- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sensor control

Results for

Sensor control - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in Hydraulic valve assembly.

Request for a quote

IGUS® GMBH

Germany

Initiator cables, also referred to as sensor/actuator cables, connect control units and different sensors, or, in the case of reversal of the measurement principle, actuators. Frequently used abbreviations include ini or ini cable (plural: inis). Sensor or measurement transducers transform physical quantities such as rotation, speed, distance or length into analogue electric impulses. In the case of an actuator, the measured electric current (symbol: I, unit: ampere; A) or voltage (symbol: U, unit: volt; V) is transformed into temperature, pressure or torque. The connection cable consists of at least three cores with a small cross-section of between 0.14mm² and 0.34mm². In the simplest case, two cores are required for supplying the voltage, while the last core transmits an I/O signal. For sensitive applications, there are shielded versions in addition to the traditional ini cables to avoid EMC disruptions (electromagnetic compatibility).

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Temperature controllers and temperature sensors from Klöpper Therm are used in all electric heating systems in which the temperatures of the heated areas must be reliably measured and controlled with precision.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Thermo Sensors are needed in any controlled heating process. For various applications different types of thermocouples are obtainable. Most common are thermocouples (TC) and resistance sensors (RS). Both types are available in the same executions as a matter of princible. For non-contact measuring infrared sensors are the rights choice, either in stationary executions or as portable measuring instrument.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Bentley-Harris® Textalu 1202 is an insulative fiberglass sleeving with a heavy aluminum coating designed to protect components in high temperature areas. It provides superior insulation to components that must maintain stable temperatures to assure performance efficiency. Textalu 1202 is used on wire harnesses, sensor control wiring and cable assemblies in close proximity to engines and exhaust systems. Due to its elastic structure, Textalu 1202 conforms well to the variable profiles of the components it protects. Its braided construction allows good flexibility in temperatures as low as -50°C. The infra-red emissivity rating of Textalu 1202 heavy aluminum coating, combined with its fiberglass braid, ensures temperature stability inside the Textalu sleeving despite frequent external temperature fluctuations due to radiant heat.

Request for a quote

VKF RENZEL GMBH

Germany

Our sensor-controlled wall disinfectant dispenser "Sensor-Wall II" is a flexible and extremely user-friendly dispenser for hygienic dispensing of hand disinfectants. The operation is contactless thanks to the integrated sensor. Simply hold your hands under the sensor for 2 seconds and your hands will be moistened with liquid disinfectant. In addition, the dosage quantity can be adjusted in 3 steps. Especially practical is that our dispenser "Sensor-Wall II" has an integrated but removable tank with a capacity of 1,000 ml. The hygiene dispenser is therefore not dependent on any particular bottle size or shape. As an option, an A4 click frame can also be mounted above the wall dispenser. This stand is operated with the mains adapter included in the scope of delivery or optionally with 6 AA batteries (not included).

Request for a quote

GSW SCHWABE AG

Germany

A stationary production aid everywhere where bigger loads have to be lifted or lowered, e.g. as loading table behind compact feed lines Stroke from 800 1600 mm Electrohydraulically driven lifting and lowering, controlled via hand sensor device (Totmann) on a 3m cable.

Request for a quote

INFICON GMBH

Germany

Powerful Yet Compact Solutions for Deployment of FabGuard FabGuard Controllers provide powerful compact solutions for deploying FabGuard integrated process monitoring solutions. These reliable industrial controllers connect with tools and sensors through FabGuard to perform real-time data acquisition and analysis, whether for detailed chamber-specific analysis or as part of a fabwide SPC & FDC system. FabGuard Controllers support INFICON sensors, third-party sensors as well as the variety of tools found throughout fabs. Even the demanding requirements of high-speed applications can be met using the FabGuard High Speed Controller.

Request for a quote

INFICON GMBH

Germany

Process Characterization Software For The Transpector Gas Analysis System With one-click access to the two most popular RGA functions: monitor and leak check modes, FabGuard Explorer provides you with easy to interpret data showing the most frequently monitored gases (hydrogen, water vapor, nitrogen, oxygen, argon, etc.) in a convenient trend display. FabGuard Explorer is Windows® 8 ready, providing comprehensive RGA software with no concerns about operating system compatibility. The single-sensor version of FabGuard Explorer is a cost-effective solution to operating one Transpector ® RGA. With the software’s multi-sensor version, you can control multiple, different types of Transpector RGAs from a single computer. FabGuard Explorer allows for control of both Transpector MPH and Transpector 2 RGAs from the same software. For connecting multiple Transpector MPH sensors, INFICON offers routers and network switches, while the TCA485 Transpector Communications Adapter is used for...

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Format 96 x 96 mm Two/three step, continuous controller Sensor monitoring Up to 5 outputs 1 Analogue input (universal) 1 Binary input 1 Relay output (closing contact) Self-optimization (autotuning) for exact PID control Manual/automatic mode Configurable limit monitoring (alarms) Setpoint switching Level/keyboard locking RS485 interface (Modbus RTU) Ramp and timer function Firing curve for ceramic furnaces Plug-in controller module Setup interface (USB Mini-B)

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Format 48 x 96 mm, portrait Two/three step, continuous controller Sensor monitoring Up to 5 outputs 1 Analogue input (universal) 1 Binary input 1 Relay output (closing contact) Self-optimization (autotuning) for exact PID control Manual/automatic mode Configurable limit monitoring (alarms) Setpoint switching Level/keyboard locking RS485 interface (Modbus RTU) Ramp and timer function Firing curve for ceramic furnaces Plug-in controller module Setup interface (USB Mini-B)

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Format 48 x 48 mm Two/three step, continuous controller Sensor monitoring Up to 5 outputs 1 Analogue input (universal) 1 Binary input 1 Relay output (closing contact) Self-optimization (autotuning) for exact PID control Manual/automatic mode Configurable limit monitoring (alarms) Setpoint switching Level/keyboard locking RS485 interface (Modbus RTU) Ramp and timer function Firing curve for ceramic furnaces Plug-in controller module Setup interface (USB Mini-B)

Request for a quote

GSW SCHWABE AG

Germany

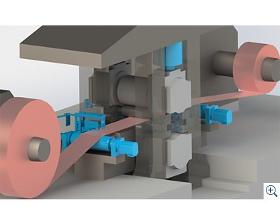

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

CAN (Controller Area Network) is a network concept that has been developed for the automotive industry originally. Today, CAN is especially used in networking industrial control systems, sensors and actuators based on the field bus technology. In our CAN-bus training you will learn about the physical properties of a CAN-bus system as well as protocol structure. The participants will look into the theory of hardware and software design and improve their knowledge in practical units. This CAN-bus training course forms the basis for our advanced-level workshops on CANopen and J1939. Target group CAN-bus training The target group of the CAN-bus workshop is development engineers who are looking for a quick start into the ISO standard 11898-1:2015 (Road vehicles – Controller Area Network). Also, we address decision makers and product managers to enable them to assess the suitability of the CAN-bus standard for their applications.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Digital pH sensor SMARTPAT analytical sensors from KROHNE are the first and only sensor line in the market with integrated transmitter technology. The complete circuitry is miniaturised and fits into the sensor head. This technical achievement cuts the price in half compared to all measurement systems without integrated transmitter technology. KROHNE is the only company who offers a real open standard without additional external transmitter and with a direct connection via standardised fieldbus from the sensor to the process control system. The SMARTPAT sensor stores all data and sends these as bidirectional digital signals with 4...20 mA / HART® 7 protocol to the control and asset management systems, handhelds, PC and other peripherals.

Request for a quote

TEST GMBH

Germany

The modernization of an existing testing machine provides a cost-effective alternative to a new acquisition. The use of existing accessory can be continued in most cases. Through the exchange of sensor, measuring and control technology as well as the installation of new safety devices an older testing facility can be brought to the current state of technology. We offer you a free assessment of the feasibility by our service or sales staff and ask you about the desired extent. On this basis you will receive our offer.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller. The device consists of an acceleration sensor, a controller unit and three types of output interface. The main feature is two safety switching contacts (potential-free), which can be used e.g. in the safety chain to undertake safety shut-off in the event of excessively high acceleration values. Data output is carried out via the CANopen interface. The standard or the safety profile can be selected. There are additionally two analogue outputs 4 ... 20 mA, which can be optionally assigned to two of the three measurement axes. Thanks to its high resistance to vibration and shock, the sensor is suitable for use in areas with rough environmental conditions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller.The device consists of an acceleration sensor, a controller unit and the output interface PROFIsafe over PROFINET for output of the acceleration values. Thanks to its high resistance to vibration and shock - more than the defined measuring range -, the sensor is suitable for use in areas with rough environmental conditions.Electrical connection is carried out using three connectors.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller. The device consists of an acceleration sensors, a controller unit and three types of output interface. Data output is carried out via two analogue interfaces with 4 ... 20 mA plus CANopen and via 4 relay contacts (currently 1 error relay contact). The NVA is parameterised via the CANopen interface. This is not galvanically separated. The sensor is equipped with a filter circuit to protect against fast transients and surge voltages of up to 2 kV in the supply. The protection types are IP 69K (housing) and IP 67 (connector/socket). With its good vibration and shock values, the sensor is suitable for use in areas with rough environmental conditions.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The O-forming press applies a press force of 4,000 metric tons per meter of pipe. This is necessary to form today’s material grades above X100 to the desired round shape at the optimum level of reduction. The control concept with (patented) multi-cylinder parallelism control ensures that the moving beam maintains a position parallel to the press table with a tolerance of +/-1 mm/m over the entire length. Combined with our tools, this results in a precise pipe gap which leads to signicant time and material savings for the subsequent welding process. The intelligent sensor and control concept of all main cylinders ensures that dierent sheet lengths (e.g., residual lengths) can be processed. The press is powered by either conventional drive concepts or via frequencycontrolled drive concepts. Our ECO Drive uses the high moving load of the moving beam to generate energy during the controlled quick lowering of the beam. This energy is fed back to the power network.

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

BlueVis: Unified Bioprocess Management. With BlueVis software bioprocesses can be monitored and controlled in an easy way. Sensors and probes can be connected independently from brand. All data will be logged and visualized in real-time. BlueVis processes the data and automatically calculates key parameters (like OUR, CTR, RQ etc.) via integrated soft sensors. Actuators like pumps, stirrers, cryostates or thermostats can be operated and controlled to optimize the process. The software offers all data to process lead systems via integrated OPC server. This way BlueVis is open in both directions. BlueVis is fair and professional solution for all paramteres and applications in bioprocessing. BlueVis: one solution for all parameters and applications.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

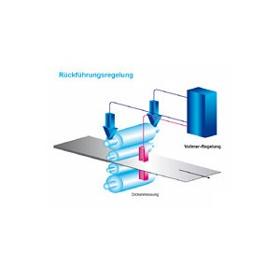

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Efficiency thanks to flat strip The use of flatness measurement alone without control already achieves a noticeable increase in productivity because strip breaks can be effectively prevented or the mill can be operated at the maximum possible speed for the particular unflatness. If the mill has the necessary adjusting elements, the Automatic Flatness Control (AFC) results in an effective improvement in quality. Control results of ± 4 I-units referred to the respective nominal curve are realistic. With our detailed know-how of the interplay between measurement, control and rolling mill we are on of the few manufacturers able to supply complete control systems for the strip shape – from the sensor through to the control of the adjusting elements From the pivoting of the rolls through to the combination of pivoting, bending, shifting of the intermediate rolls and zone cooling and far more – we have a command of the whole spectrum of shape control.

Request for a quote

TKD KABEL GMBH

Germany

TKD | 03 BUS, LAN, FO-, coaxial & video cables in the field of production automation for reliable data and energy transmission (e.g. between sensors, actuators and controllers), for high flexible applications (e.g. power chains, gantry robots, pick&place units, conveyors, machine tools, automated production systems, etc.) - BUS | FIELDBUS technology – for industrial, process & building automation - LAN | ETHERNET-Technologie –for structured industry & building cabling - FO BUS-Technologie – optical data transmission - Coaxial & video cable Excerpt of versions: > shielded, unshielded > UV-resistant, Oil-resistant > UL/CSA recognized, listed > for fixed installation > for high flexible drag chain & robotic applications Excerpt of products: PROFIBUS - MULTIBUS - INTERBUS - CAN BUS - DeviceNet - FoundationFieldbus - ASi-BUS - SafetyBUS - EIB/KNX BUS - PROFINET - INDUSTRIAL ETHERNET Cat.5e...Cat.7A - POF - SIMPLEX, DUPLEX

Request for a quoteResults for

Sensor control - Import exportNumber of results

25 ProductsCompany type

Category

- Sensors (5)

- Measurement - Equipment & Instruments (3)

- Temperature sensing devices (3)

- Electric cables (2)

- Industrial valves, operating equipment (1)

- Electroheat - machines and equipment (1)

- Electronic data processing - microcomputers (1)

- Forming - steels and metals (1)

- Induction heating systems (1)

- Machine tools, metal shaping - parts and accessories (1)

- Metal straightening machines (1)

- Plate glass and mirrors (1)

- Software, technical and scientific (1)

- Thermal insulation materials (1)

- Water distribution (1)