- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- alloy ores

Results for

Alloy ores - Import export

ALUMINIUMWERK UNNA AG

Germany

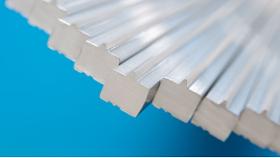

With the unique extrusion process, ALUnna has the capability to produce continuous lengths of extruded profiles. Unlike the conventional extrusion process, the continuous extrusion process does not use billets. Instead, raw material is fed into the process from a coil. This process is especially useful for the production of small extrusion profiles used as spacer bars in alloys EN AW-1050A / 1350A or EN AW-3103/3003. If necessary, there is an option to apply a draw pass to the spacer bar profile using an in-line Schumag continuous drawing machine in order to achieve the final dimension and the most demanding of tolerances.

Request for a quote

INFICON GMBH

Germany

SIMPLE OPERATION FOR MANY APPLICATIONS STM-2XM is a two channel rate/thickness monitor that combines high accuracy with flexible programming and easy operation at an affordable price. STM-2XM is equipped with five operation modes to accommodate processes from simple to complex. For example, use simple mode to monitor just one single sensor for the simplest process or use alloy mode for codeposition monitoring. Independent mode allows STM-2XM to function as two completely separate monitors. Two sensor inputs allow for the use of two single or one dual quartz crystal sensor. 10 measurements are taken per second while achieving a resolution of 0.037 Å per measurement (density of 1). FEATURE PACKED STM-2XM has eight programmable digital inputs, eight programmable digital outputs, and four analog outputs allowing for a level of integration usually reserved for more expensive instruments. Programmable features include shutter delay, time/power monitoring, and rate sampling. Use...

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Good formability and conductivity make our products useful for condenser case products produced via drawing processes. Manufacturers of these aluminum case applications rely on Novelis to provide high-quality aluminum coils or sheet in alloys such as 1050 and 3004. Novelis produces pre-painted aluminum for scales, dials and nameplates in laser engraving quality, in the form of a surface-treated coil or sheet. Specialized coatings are applied by rollers. Printing is possible via standard commercial inks and paints with no special materials required.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

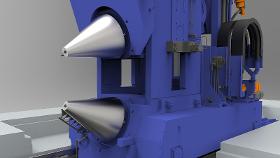

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MINEON HANDEL GMBH

Germany

Black Powder Coated Zinc Alloy or PA6 Housing and Handle,90 degree handle rotation combines with rod latch to open or close,Easy Installation,ROHS compliance

Request for a quote

MINEON HANDEL GMBH

Germany

Black Powder Coated or Anodizing Aluminum Alloy Handle,different Lengths available,with L=100mm handle,can bear a maximum static load 2500N.Easy Installation,ROHS compliance.

Request for a quote

MINEON HANDEL GMBH

Germany

Black Powder Coated Zinc Alloy Housing and Handle,with or without button,Quick Open,Easy Installation,ROHS compliance

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quoteResults for

Alloy ores - Import exportNumber of results

10 ProductsCompany type