- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dosing system

Results for

Dosing system - Import export

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ Valve sizes from DN 15 - DN 50 ■ up to 16 mixtures fully automatically in unattended night-time operation ■ Scale size: 1500 kg; 20 g indicated scale resolution ■ Dosing accuracy +/- 20 g ■ Parallel dosing on several scales ■ Barcode-supported dosing ■ quick adaptation to dosing containers between 150 l and 1500 l ■ customised container transport systems ■ integrated, environmentally friendly extraction at the current dosing point ■ optional: Pipeline planning and design ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Our systems dose in parallel into stationary and mobile tanks. The systems work with mass flow meters or measuring cells and scales. Dosing cluster ■ Dosing of large components for mixtures up to 12 tonnes ■ Stationary or mobile tanks ■ Flow rate: 30 - 250 litres/min ■ Parallel dosing with several scales or with mass flow meters ■ Barcode-supported dosing ■ Unattended operation ■ Integrated suction on the dosing cluster ■ Different weighing ranges ■ Explosion protection according to Atex The advantages are obvious: simply add the remaining large components to your premixes - in a single additional work step - and of course with barcode support and fully automatically. With our modern storage systems, you can remove large components from several drums simultaneously at any time. Labour and cleaning-intensive pumping from drums into mixing containers is a thing of the past.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Duplex dosing system - optimised utilisation thanks to two scales 2 Scales in a single dosing system? A demand evaluation of dosing statistics from medium-sized perfume and aroma manufacturers as well as of similar demands from smaller sites of the top 10 F&F producers pointed to exactly that. 2 Scales because downtimes can thus be reduced to a minimum and a larger weight range can be covered. From fully automatic dosing on a small scale (up to 50 litres) to larger batches with up to 600 litres. As usual with FRICKE, the modular dosing units of the Duplex can also be flexibly expanded. OverView of performance data ■ 30 or 60 kg scale ■ 600 or 1.500 kg scale ■ Smallest pour 0,5 g ■ Batch sizes from 5 to 600 litre ■ Fully automatic container container intake ■ Flexible storage desing for raw materials ■ Fast mixing container exchange ■ Unsupervised machine operation ■ Optionally: Mixing station and powderdosing ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing systems for production mixtures up to 1500 kg batch size Our machines offer a wide range of options for process optimisation. Equipped with valves of different sizes, they ensure maximum speed and accuracy. The use of several scales in one system significantly increases productivity, creates free capacity and enables on-time production with a 50% increase in output. ■ up to 16 fully automatic mixing recipes during the unattended night shift ■ scale sizes: 300/600 kgs; 1 g / 2 g indicated scale resolution ■ dosing accuracy: +/- 5 g / +/- 6 g ■ parallel dosing on several scales ■ valve sizes from DN 15 to DN 50 ■ fast adaptation to dosing containers between 75 litres and 600 litres ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound extraction system directly at the dosing point ■ Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 mixes automatically in night mode ■ 2000 doses per day ■ Liquid dosing up to 25 kg batch size ■ Scales with 30 kg or 60 kg capacity and 10 mg or 20 mg indicated scale resolution ■ 50 mg or 60 mg dosing accuracy ■ DN 8 valves ■ Parallel dosing for high speed ■ Barcode-supported dosing ■ Customisable system sizes and container transport systems ■ Integrated environmentally friendly extraction system ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Dosing system for laboratory and small scale production mixes up to 6 kg batch size Space-saving this system combines all advantages of a laboratory dosing system to the production capacity of the larger systems Concordia II – V (C 2 – 5). ■ batch sizes up to 6 kg ■ more than 130 fully automatic mixing recipes during the unattended night shift ■ 7000 dosing cycles per day ■ dosing precision on the 6 kg scale: +/- 5 mg ■ smallest dosable quantity on the 6 kg scale: 20 mg ■ modular design for up to 1000 components ■ barcode assisted dosing ■ high dosing speed through parallel dosing on several scales ■ individual container transport Systems ■ various raw material storage Systems ■ Ex protection according to Atex

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The Dosing Star is characterised by its very high dosing accuracy at maximum dosing speed. The design is modular. Each module has its own scale. In addition to the variable number of dosing modules with the valve containers, the Dosing Star has a linear gantry for distributing the batch containers to the individual modules. Up to 25 mixing containers are each placed on a tray trolley. Four trolleys can now be conveniently pushed into the system. Thanks to the modular design of the dosing system, it is possible to connect up to 8 dosing modules to the linear gantry. A maximum of 128 valve containers can be stored in each of the dosing modules. ■ Fast dosing in containers with an opening diameter from approx. 15 mm ■ Gripping system for time-optimised distribution of the mixing containers to up to 8 dosing modules ■ Fixed and flexible barcodes can be used ■ Rush orders are optimally integrated into the production process

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Creative and sampling laboratories are familiar with the problem: cramped premises with no alternatives, hardly any space for the extensive ingredients and tight deadlines. Specially developed for office buildings, the modular and space-saving laboratory systems can automate up to 600 components with maximum precision. From now on, fast presentations of mixtures will be a further advantage for your company. ■ 34 mixtures fully automatically in unattended night-time operation ■ Optionally up to 54 mixes ■ 2,000 doses per day ■ Barcode-supported dosing ■ Dosing accuracy with 6 kg scale: ±3 mg ■ Smallest dosing quantity with 6 kg scale: 5 mg ■ Mixtures up to 1 000 ml ■ Quick presentation of dosing results ■ cooled and heated components ■ Modular design for different sizes (100-500 components) ■ Integrated storage system

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

FRICKE dosing systems make it possible to integrate rush orders into the ongoing production process without interruption, allowing schedules and workflows to be adhered to. Thanks to extensive accumulation sections for mixing containers and multi-pot mixtures, unattended night-time operation is also possible. The batch management software ensures that all orders are processed safely and efficiently. ■ 40 fully automatic mixing recipes during the unattended night shift ■ 2000 dosing cycles per day ■ for liquid dosing up to 120 kg batch size ■ 150 kg scale, 0.1 g indicated scale resolution ■ dosing accuracy +/- 0.5 g ■ DN 8/15 valve ■ high dosing speed through parallel dosing on several scales ■ barcode assisted dosing ■ individual container transport systems ■ integrated, environmentally sound ■ extraction system directly at the dosing point ■ optional: Pipe system engineering and execution ■ Ex protection according to Atex

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Dosing systems for all common lubricants. With the Jerko concentration calculator you get always the right mixture no matter what density the medium has. The dosing systems are available as stand alone solutions or as an optimal addition to our systems or existing spraying system.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige has years of expertise in continuous granulation. Nowadays, continuous ringlayer mixers are established systems for continuous granulation in many industries. However, until now the Lödige product range was missing a suitable dryer. The continuous fluid bed dryer closes this gap. Together with the ringlayer mixer CoriMix® and the customer-specific dosing system, this dryer provides a complete continuous granulation line: GRANUCON®. Dryer operation is based on the fluid bed process. A general disadvantage of continuous fluid beds is the wide retention time distribution within the machine. Lödige’s developers have looked into this problem and have found a solution: integrating a screw in the fluid bed dryer. This has a limiting effect on the retention time distribution. — Exchangeable floor — Quick screw removal — Integrated WIP cleaning — Individual purging of filter elements

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The DK32/34 is a variable area (VA) flowmeter for measuring low flow rates of liquids and gases. The tried and tested meter is particularly suitable for flow monitoring and dosing in gas analyser systems or on purge panels. Due to its robust all-metal design it can also be used in difficult process conditions with temperatures up to +200°C / +392°F or pressures up to 400 barg / 5800 psig. It is available with a metering valve as standard to accurately set the flow value. The DK32/34 operates without auxiliary power supply. The device just features a local indication with two optional MIN/MAX limit switches (NAMUR) or a reed contact. To provide constant flow rates in case of variable inlet or outlet pressures, the VA meter is also available with flow regulators. It comes with horizontal or vertical process connections for NPT or G thread and many other connection options. The VA meter has various approvals for hazardous areas.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Until now, the perfume and flavouring industry had hardly any satisfactory solutions for the exact mixing of powdery substances, which often led to weighing errors, blocked valves and production downtimes. The FRICKE PD1 powder dosing system was specially developed to meet these challenges. With a 6 kg scale (1 mg resolution), it automates the dosing of 20 powder components, which are stored in sealed stainless steel containers (10 litres). Various dosing elements and stirrers enable lump-free and dust-free processing. The advantages include high accuracy, reproducibility and simple software integration into the batch management system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIXACO MASCHINENBAU

Germany

The MIXACO discharge stations are used for dust free emptying of the product into the further processing step (e.g. dosing system into an extruder). The container is fixed in place when moved into the discharge station. Two different executions are available: Type Guide fork Type Platform Differentiated by the way of feeding the container. Type Guide fork The movable container is pushed by means of its own wheels into the discharge station type guide fork and is locked in place. A pneumatic coupling is used to connect the discharge pipe to the container discharge valve. Type Platform The container is placed onto the emptying station with the aid of a lifting device (crane or forklift). Equipment Positioning of the container Pneumatic coupling between container and the further production step Pneumatic rotary cylinder for automatic opening / closing of the container discharge valve (0/90°)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

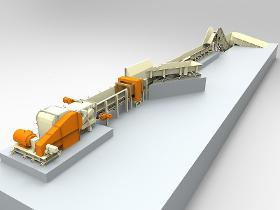

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

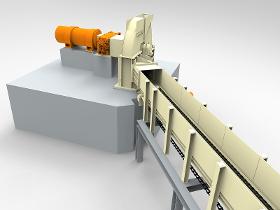

The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-ecient disc and drum chippers as well as the mills for the preparation of bark, the production of highquality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Dosing step conveyor for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Depending on the debarking demand, use of drum or rotor debarker Disk or drum chipper Advantages Robust, highly controllable wood feed Debarker adapted to the debarking demand Minimal ne material content High lling level and high utilization of chipper capacity High operational safety

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quoteResults for

Dosing system - Import exportNumber of results

23 ProductsCompany type

Category

- Weighing and dosing equipment (10)

- Wood veneer - machinery and equipment (4)

- Foams, rubber (2)

- Pharmaceutical industry - machinery and equipment (1)

- Dosing - machines and equipment (1)

- Plastics - machines and material for industry (1)

- Bottling and filling - machinery and equipment (1)

- Flowmeters (1)

- Transport, indoor - rolling equipment (1)