- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt transporters

Results for

Belt transporters - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

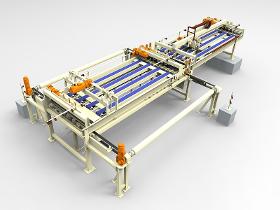

It is possible to reliably remove reject boards without aecting the cycles in the rejects area. Acceptable boards continue to be transported towards the cooling turner. The rejected board stack may optionally be equipped with batch and package forming systems. These are for optimising the cooling turner utilisation and are explained in greater detail in the chapter about the ‘Cooling section’. The rejected board stack is equipped with a variable length adjuster or board lifter for the batch and package forming options. Reject boards are removed by lifting the rst belt conveyor. The rejected board stack may be optionally equipped with a buer for forming the reject stacks or with an additional belt conveyor that transports the rejects to the board breaker.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

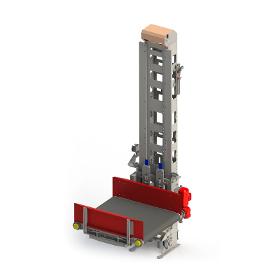

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules. The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible. Any Height Requirements Low overall height possible with integrated belt tracking device. Floormounted version or suspension from the ceiling incl. individually adjustable height and angle are also available.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

requires little space uncomplicated change of replacement brushes Edging nylon, wire, nylon/wire mixture, rubber, other edgings possible upon request. Areas of use belts with profile, cleat belts, old and damaged belts, belts for the transporting of glass etc

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Venjakob has combined – for the first time in the industry – a robot with a surface spray painting machine. VEN SPRAY VARIO offers the flexibility of an industrial spray coating robot and the high output of an automatic surface spray coating machine. The outer edges of the parts are precisely coated by the robot, and the surfaces are sprayed "inline" at a constant throughfeed speed without any stopping or stop and go by the spray guns of the downstream linear axis. In comparison to the usual Cartesian robot systems on the market, this leads to an approx. 50 % higher lacquering performance(surface|minute). In addition, the new system technology optimises the surface quality, as it leads to visibly better results by linking the paint film at transitions from surfaces to outer edges. Another decisive system advantage of the VEN SPRAY VARIO is the ongoing guarantee of reproducible production qualities. The perfect finish of 3D workpieces is particularly impressive. For coating complex 3D parts as a stationary batch we recommend using the optionally available paper belt transport system. In addition to the described flexibility, the plant technology can also be used for surface coating only. As an alternative to a manual spraying station a single robot can be used for complex geometries. The technically sophisticated paint recovery system achieves maximum efficiency. The recyclability of the recovered overspray and the considerably reduced use of cleaning agents provide an impressive energy balance. In addition, the efficient ventilation technology noticeably reduces the resulting energy costs. The modular design ensures a safe investment in the long term. The integration of additional robots and other adjustments to meet the continuously growing demands on our customers' production processes are possible at any time.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The VEN BRUSH system technology is based on high pressure at low speed. Special hold-down brushes with wide support brushes or narrow support brushes for processing profiled workpieces, ensure the required pressure. For the pretreatment of workpieces of varying shapes or extremely fluctuating sizes, maximum perfection and flexibility are provided by the motor-driven height adjustment of each individual unit as well as by the infinite rotational speed setting. The high-performance vacuum transport belt ensures reliable transport and holds both small as well as large format workpieces in place. A Molton roller is built in to ensure constant cleaning of the conveyor belt. Unit diversity results in a wide performance spectrum and generates a high economic effect. The basis version of VEN BRUSH allows a selection of 2 unit positions to up to 5 unit positions. To be prepared for possibly changing requirements in your production process, you can also select the next larger variant and equip the free unit position as required at a later date. System examples for possible operating widths from 600 to 3,500 and operating lengths from 2,000 to 5,500 mm. Depending on your production requirements, you can individually select from: Short change times and high operating comfort are possible thanks to the quick-exchange brush system using a push-in system together with a coupling. The optional infinite angle setting of the round brushes permits impeccable edge processing. The use of the structured brush unit is intended for special surface processing. This brush is used to structurise furniture parts, hardwood and softwood, flooring boards or to provide an antique look of up to 1 mm deep at a throughfeed speed of 10 m/min. Where required, the VEN BRUSH can be extended by a dust removal system with rotating blow nozzles and ionisation system. Following a brushing or sanding/grinding effect, this complementary function ensures optimum workpiece cleanliness to meet high requirements. As an individual solution, VEN BRUSH convinces as a station in a Venjakob machine line or when integrated in an existing machine line. As such, control system configuration takes all interfaces into account, through to higher ranking control and monitoring. The high-performance system technology can be easily operated directly using a control panel or a touch panel.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 HighSpeed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157 Operational Safety High level of operational safety through the strip design. Smooth Transfer Closed belt surface for a smooth package transfer. Belt Tracking Integrated Automatic belt track fittings integrated. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low structural height. (approximately 250mm)

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

Beam machine for irradiating a glass sheet conveyor belt Transport device supporting roller guide, motor nozzle movement, infinitely variable, attached dust filter system and electronic Control. Max. Lens height for automatically rays 1.200 mm Max. Lens height for manually rays 1.500 mm

Request for a quoteResults for

Belt transporters - Import exportNumber of results

10 ProductsCompany type