- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt transporters

Results for

Belt transporters - Import export

ROBINSON CO.

Turkey

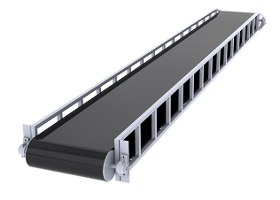

It transports the bagged product from one place to another, the combined belt conveyor supports the belt conveying process. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

PARSMEGA MAKINA

Turkey

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper belt coatings The coatings for timing belts, V-belts, flat belts and transport belts always are selected so that they are optimally suited for the product to be transported and/or the intended transport purpose. Many innovative and structural tasks, which may call for pacing, separating and positioning in the material flow, can be realized by adding profiles and entraining elements.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU wide timing belts are made of abrasion-resistant polyurethane and high-strength aramid cords in widths up to 600mm. These timing belts are specially designed for synchronous transport applications. In view of the production width as well as outstanding mechanical and chemical properties, they can be used for many applications. Moreover, it is possible to use special materials such as, for example, polyurethane that is suitable for contact with foodstuffs, or a nylon coating on the tooth facing and back side. Properties and special features: High-strength aramid tension cords Parallel arrangement of tension cords for even distribution of tension Form-fit, synchronous running Low-noise, high abrasion resistance and flexibility Applications: As a substitute for transport belts for synchronous positioning Applications in the foodstuffs industry Sausage, meat and cheese processing Conveying of bulk goods

Request for a quote

STATEC BINDER GMBH

Austria

Our product portfolio includes three manual bagging machines for open-mouth bags: SCALPAC-G, SCALPAC-B, SCALPAC-S. All three bagging systems are designed for up to 1200 bags per hour and differ only in the used net weighers. Depending on the product to be filled, a net weigher with gravity, belt or screw feeding is used. Prefabricated open-mouth bags made of woven PP, PE or paper are attached to the filling clamp and fixed by an employee. As soon as the bag is fixed, the weighed product flows into the bag. A conveyor belt transports the filled bag to a bag closing machine, which sews, seals or hot-glues the bag depending on the material. For free-flowing bulk materials, a net weigher with gravity feeding is selected. Moderately flowing products are fed via a belt feeder. For fine and powdery products, the screw feeder is best suited.

Request for a quote

STATEC BINDER GMBH

Austria

As the name suggests, the FFS-Combi Version of the open-mouth bagging machines has an additional FFS module, allowing bags not only to be used from the bag magazine but also to be produced from tubular film. The CERTOPAC and PRINCIPAC open-mouth bagging machines are available as FFS-Combi Versions. The additional FFS module is also available for the CIRCUPAC bagging carousel. The changeover from the bag magazine to the production of bags from the tubular film is simple and convenient on the operating panel. The filling process is identical for both variants. The bags are either separated from the bag magazine or produced from tubular film and conveyed to the pick-up station. There the bag is put onto the filling spout, filled, and placed on the conveyor belt. From there it is transported to the bag closing machine, which sews, seals, or glues the bag depending on the material.

Request for a quote

STATEC BINDER GMBH

Austria

The Twin Version of the open-mouth bagging machine combines two bag placers and two filling stations in one machine. Two STATEC BINDER high-performance net weighers ensure that the product is precisely dosed and weighed. When the required weight is reached, the weigh hopper opens and the product flows into the attached bag at the filling spout. A high-performance bag closing machine enables fast sewing, sealing, or gluing of the bags. The high performance of the Twin Version is achieved by always separating two bags simultaneously, transporting them to the pick-up station, fixing them onto the filling spout, filling them, and placing them on the conveyor belt. The bags are then transported one after the other to the bag closing machine. For example, the PRINCIPAC-Twin can handle up to 2400 bags per hour with a filling weight between 10 kg and 50 kg.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Metalworking’s most versatile belt conveyors for transporting a broad range of materials. More versatile than other types of conveyors. PRAB steel belt conveyors can be used to handle any type of wet or dry metal scrap- from bushy material and die scrap, to chips and turnings. This heavy-duty scrap conveyor can process wet or dry metal material in any volume and is available in a wide variety of paths

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

CARBOMECH SP. Z O.O.

Poland

People's platforms are designed to enable safe boarding or alighting on or off the conveyor belt while transporting people by belt conveyors. The platforms are adapted to be installed on belt conveyors of any parameters. Additionally, with the platforms, a structure is used to install limit switches, sensors and elements of electrical equipment necessary to maintain safety.

Request for a quote

MAFDEL

France

Ridge-top v-belts allow minimizing the contact between the belt and the transported product. They are particularly adapted to tiles, bricks, ceramics… MAFDEL proposes 2 types of ridge-top v-belts: - Standard ridge-top belts: Made in a single material, they are available in DEL/FLEX red and SOUPLEX white aramide reinforced. - TOPGRIP ridge-top belt: Flexible and resistante, the TOPGRIP ridge-top can be bonded to all the range of v-belts (except DEL/ROC).

Request for a quote

DOREY

France

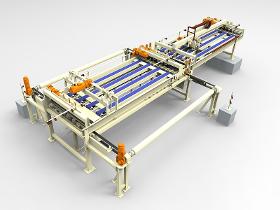

Extraction of individual cards from two removable loading magazines The timing belt transporting system moves the cards from one workstation to another in a synchronizes manner Card thicjness measuring station ensuring only one card is fed CNC cavity high speed milling head for up to 60,000 RPM and dust extraction Hot melt tape spoller, puncher, laminating and peel off system to laminate with chip module tape Chip module punching station and pick & places system for chip module implanting in the cavities Bonding on chip into the card cavity Cooling press qtation Data input device Sorting of cards into good and reject magazines PC based control for easy operation Production capacity of up to 3,000 cards per hour Smooth, low impact operation reduces the noise level of hot melt adhesive Modular design Integrated hot melt lamination system Very stable ans consistent production process

Request for a quote

DOREY

France

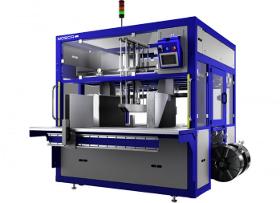

The machine is fully automatic punching and stacking system for GSM cards (Global System for Mobile Communications). It is designed to punch the Subscriber Identity Module (SIM) and scribe a break out line according to the GSM 11.11 standard. BENEFITS Extraction of Individual cards from two removable loading magazines. The timing belt transporting system moves the cards from one workstation to another in a synchronized manner. SIM punching operation is driven by hydraulic system. Scribing of break out lines with pneumatic driven tool knife edge. Removal of waste material into an external container. Automatic stacking of the finished cards in two output removable magazines. Complete CE safety guards. The touch screen monitor makes the machine easy to operate and self diagnostic trouble shooting makes the machine user friendly.

Request for a quote

PKO-SURA COMPANY

Russia

The СУРА-СП forming machine is designed for molding sugar cookies onto a belt with a further transportation to a wire-mesh plate of tunnel oven. The forming drum is one of the main units of the forming machine. It is a part of this machine and used for forming one type of cookies that have defined shape and pattern. At the request of the Customer, we can manufacture any number of drums with any pattern and shape of cookies. The patterns and shapes are chosen according to the catalogue.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Different types of films and cushion types can be produced on our low-cost AirBoy nano3. Therefore you have the best flexibility for your transport protection, even with low throughput.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 Standard starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions. The Metzner ST-OB is for cutting cables & strands up to 30 mm diameter. Thanks to the gentle adjustment of the pressure between the transport belt also optimal for cutting rubber seals. WIDE SPECTRUM The cut-to-length machines of the ST-OB range have convincing precision, compact construction and processing spectrum for products such as cables, wires, braided cables, shrink-fit tubes, and numerous other materials.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium system has stood the test of time for transporting general cargo across long distances. The design allows for non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer serpentine conveyor has stood the test of time for transporting general cargo vertically. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. The chain is optionally equipped with rubberised elements so that large gradient angles can be overcome. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. By connecting a serpentine conveyor that conveys upward and one that conveys downward, the machine can be used as a storage system. Technical data —Conveyor body material: stainless steel —Gradient angle: up to 6° —Chain widths: 82.5 mm, 114.3 mm, 190.5 mm —Conveying speed: up to 50 m/min —Product weight: up to 5 kg Optional equipment —Moving deflecting pulleys —Product guides,design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —accessories: sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygienic system has stood the test of time for transporting general cargo across long distances. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data —Conveyor body material: stainless steel —Conveyor body width: 106 mm, 131 mm, 206 mm —Chain width: 82.5 mm, 114.3 mm, 190.5 mm —Conveyor speed: up to 80 m/min Optional equipment —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium compact system has stood the test of time for transporting small products in very tight spaces. The design allows for a mostly non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is possible to reliably remove reject boards without aecting the cycles in the rejects area. Acceptable boards continue to be transported towards the cooling turner. The rejected board stack may optionally be equipped with batch and package forming systems. These are for optimising the cooling turner utilisation and are explained in greater detail in the chapter about the ‘Cooling section’. The rejected board stack is equipped with a variable length adjuster or board lifter for the batch and package forming options. Reject boards are removed by lifting the rst belt conveyor. The rejected board stack may be optionally equipped with a buer for forming the reject stacks or with an additional belt conveyor that transports the rejects to the board breaker.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

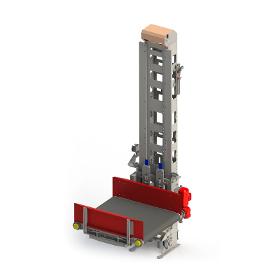

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quoteResults for

Belt transporters - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Conveyor belts (11)

- Furnishings, cushioned (5)

- Packing and packaging - machinery and equipment (5)

- Conveyor systems (3)

- Cutting - machine tools (2)

- Goods handling systems, continuous (2)

- Automation - systems and equipment (1)

- Bakery - machinery and equipment (1)

- Flour-milling (1)

- Food Industry - Machines & Equipment (1)

- Games and toys (1)

- Industrial cutting machine tools (1)

- Internal transport systems (1)

- Mechanical engineering - custom work (1)

- Metal brushes (1)

- Mining and quarrying - machinery and equipment (1)

- Moulding, rubber - machinery (1)

- Oils, cooking - machinery and equipment (1)

- Package stamping machinery (1)

- Packaging recycling (1)