- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt transporters

Results for

Belt transporters - Import export

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper belt coatings The coatings for timing belts, V-belts, flat belts and transport belts always are selected so that they are optimally suited for the product to be transported and/or the intended transport purpose. Many innovative and structural tasks, which may call for pacing, separating and positioning in the material flow, can be realized by adding profiles and entraining elements.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU wide timing belts are made of abrasion-resistant polyurethane and high-strength aramid cords in widths up to 600mm. These timing belts are specially designed for synchronous transport applications. In view of the production width as well as outstanding mechanical and chemical properties, they can be used for many applications. Moreover, it is possible to use special materials such as, for example, polyurethane that is suitable for contact with foodstuffs, or a nylon coating on the tooth facing and back side. Properties and special features: High-strength aramid tension cords Parallel arrangement of tension cords for even distribution of tension Form-fit, synchronous running Low-noise, high abrasion resistance and flexibility Applications: As a substitute for transport belts for synchronous positioning Applications in the foodstuffs industry Sausage, meat and cheese processing Conveying of bulk goods

Request for a quote

IFA TECHNOLOGY GMBH

Germany

We consider your individual requirements and build customised batching plants for you. Batching plants are an important component in the system processes for the delivery, storage, dosing and mixing of raw materials and form the basis for a high-quality end product. In addition to the storage of raw materials, this also includes the processing of individual components or the finished product. IFA Technology offers you turnkey and customised complete plants in various designs, which are specially manufactured for the chemical and building materials industries. We design batch plants as tower plants that make predominant use of gravity transport or as series plants with belt transport.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Different types of films and cushion types can be produced on our low-cost AirBoy nano3. Therefore you have the best flexibility for your transport protection, even with low throughput.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 Standard starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions. The Metzner ST-OB is for cutting cables & strands up to 30 mm diameter. Thanks to the gentle adjustment of the pressure between the transport belt also optimal for cutting rubber seals. WIDE SPECTRUM The cut-to-length machines of the ST-OB range have convincing precision, compact construction and processing spectrum for products such as cables, wires, braided cables, shrink-fit tubes, and numerous other materials.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

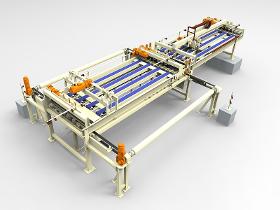

The Gronemeyer aluminium system has stood the test of time for transporting general cargo across long distances. The design allows for non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer serpentine conveyor has stood the test of time for transporting general cargo vertically. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. The chain is optionally equipped with rubberised elements so that large gradient angles can be overcome. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. By connecting a serpentine conveyor that conveys upward and one that conveys downward, the machine can be used as a storage system. Technical data —Conveyor body material: stainless steel —Gradient angle: up to 6° —Chain widths: 82.5 mm, 114.3 mm, 190.5 mm —Conveying speed: up to 50 m/min —Product weight: up to 5 kg Optional equipment —Moving deflecting pulleys —Product guides,design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —accessories: sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygienic system has stood the test of time for transporting general cargo across long distances. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data —Conveyor body material: stainless steel —Conveyor body width: 106 mm, 131 mm, 206 mm —Chain width: 82.5 mm, 114.3 mm, 190.5 mm —Conveyor speed: up to 80 m/min Optional equipment —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium compact system has stood the test of time for transporting small products in very tight spaces. The design allows for a mostly non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is possible to reliably remove reject boards without aecting the cycles in the rejects area. Acceptable boards continue to be transported towards the cooling turner. The rejected board stack may optionally be equipped with batch and package forming systems. These are for optimising the cooling turner utilisation and are explained in greater detail in the chapter about the ‘Cooling section’. The rejected board stack is equipped with a variable length adjuster or board lifter for the batch and package forming options. Reject boards are removed by lifting the rst belt conveyor. The rejected board stack may be optionally equipped with a buer for forming the reject stacks or with an additional belt conveyor that transports the rejects to the board breaker.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

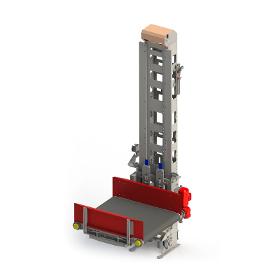

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules. The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible. Any Height Requirements Low overall height possible with integrated belt tracking device. Floormounted version or suspension from the ceiling incl. individually adjustable height and angle are also available.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

requires little space uncomplicated change of replacement brushes Edging nylon, wire, nylon/wire mixture, rubber, other edgings possible upon request. Areas of use belts with profile, cleat belts, old and damaged belts, belts for the transporting of glass etc

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SELECTIO Selective soldering systems for automatic single point soldering and multiple point soldering It is not always possible to use mass soldering processes such as wave soldering to perform a certain soldering task. Individual soldering steps are often necessary. To automate this process and to lower the costs while maintaining the high quality requirements, STRECKFUSS SYSTEMS has developed the selective soldering system SELECTIO. Just like our wave soldering system TITANIUM, SELECTIO too is equipped with the corrosion and tin resistant agent titanium and therefore works perfectly for lead free soldering. Product characteristics – an overview: x/y/z- axes system with precision toothed drive belt transport system and assembly carrier standard stand- alone- system (offline system): optional transportation belt connection as inline system printed circuit board transportation with assembly carrier soldering processes: single point nozzle and surface nozzle as well as dip soldering via mask technique fluxing out of vendor's flux container with multi- drop- fluxer nozzle short wave IR- quartz- radiators for preheating of printed circuit boards pyrometer for contact- free temperature check of printed circuit boards easily exchangeable soldering nozzles Microsoft© Windows user surface and process visualization: - BDE for documentation complying with DIN ISO 9000 ff - management data organization - optional real- time video surveillance

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This patented system equipment allows the workpieces to protrude beyond the curve dimension. Gentle and smooth running transport is guaranteed, from the small part to large surface workpieces. The picture shows a VEN TRANS CURVE application for the targeted and space saving return of large format workpieces by means of a 180° conveyor belt curve. The transport curves are available in various dimensions and angles (20 - 200°). VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Venjakob has combined – for the first time in the industry – a robot with a surface spray painting machine. VEN SPRAY VARIO offers the flexibility of an industrial spray coating robot and the high output of an automatic surface spray coating machine. The outer edges of the parts are precisely coated by the robot, and the surfaces are sprayed "inline" at a constant throughfeed speed without any stopping or stop and go by the spray guns of the downstream linear axis. In comparison to the usual Cartesian robot systems on the market, this leads to an approx. 50 % higher lacquering performance(surface|minute). In addition, the new system technology optimises the surface quality, as it leads to visibly better results by linking the paint film at transitions from surfaces to outer edges. Another decisive system advantage of the VEN SPRAY VARIO is the ongoing guarantee of reproducible production qualities. The perfect finish of 3D workpieces is particularly impressive. For coating complex 3D parts as a stationary batch we recommend using the optionally available paper belt transport system. In addition to the described flexibility, the plant technology can also be used for surface coating only. As an alternative to a manual spraying station a single robot can be used for complex geometries. The technically sophisticated paint recovery system achieves maximum efficiency. The recyclability of the recovered overspray and the considerably reduced use of cleaning agents provide an impressive energy balance. In addition, the efficient ventilation technology noticeably reduces the resulting energy costs. The modular design ensures a safe investment in the long term. The integration of additional robots and other adjustments to meet the continuously growing demands on our customers' production processes are possible at any time.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The VEN BRUSH system technology is based on high pressure at low speed. Special hold-down brushes with wide support brushes or narrow support brushes for processing profiled workpieces, ensure the required pressure. For the pretreatment of workpieces of varying shapes or extremely fluctuating sizes, maximum perfection and flexibility are provided by the motor-driven height adjustment of each individual unit as well as by the infinite rotational speed setting. The high-performance vacuum transport belt ensures reliable transport and holds both small as well as large format workpieces in place. A Molton roller is built in to ensure constant cleaning of the conveyor belt. Unit diversity results in a wide performance spectrum and generates a high economic effect. The basis version of VEN BRUSH allows a selection of 2 unit positions to up to 5 unit positions. To be prepared for possibly changing requirements in your production process, you can also select the next larger variant and equip the free unit position as required at a later date. System examples for possible operating widths from 600 to 3,500 and operating lengths from 2,000 to 5,500 mm. Depending on your production requirements, you can individually select from: Short change times and high operating comfort are possible thanks to the quick-exchange brush system using a push-in system together with a coupling. The optional infinite angle setting of the round brushes permits impeccable edge processing. The use of the structured brush unit is intended for special surface processing. This brush is used to structurise furniture parts, hardwood and softwood, flooring boards or to provide an antique look of up to 1 mm deep at a throughfeed speed of 10 m/min. Where required, the VEN BRUSH can be extended by a dust removal system with rotating blow nozzles and ionisation system. Following a brushing or sanding/grinding effect, this complementary function ensures optimum workpiece cleanliness to meet high requirements. As an individual solution, VEN BRUSH convinces as a station in a Venjakob machine line or when integrated in an existing machine line. As such, control system configuration takes all interfaces into account, through to higher ranking control and monitoring. The high-performance system technology can be easily operated directly using a control panel or a touch panel.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 HighSpeed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157 Operational Safety High level of operational safety through the strip design. Smooth Transfer Closed belt surface for a smooth package transfer. Belt Tracking Integrated Automatic belt track fittings integrated. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low structural height. (approximately 250mm)

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Cleats with heights from 20 mm to up to 280 mm Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials We produce cleats in 4 different designs: T, C or TC cleats as well as multi-part cleats. Our germanWell® cleats for corrugated sidewall conveyor belts are available in standard quality and in oil or grease resistant quality and with or without biased fabric. Please see our product brochure for more details on weights, dimensions and qualities.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanWell® Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials We use self-produced sidewalls with profile heights from 40 mm to up to 300 mm. In combination with our cleats, which we also manufacture ourselves, we can design and produce the optimal corrugated sidewall belt whatever the individual case. Our germanWell® corrugated sidewalls for sidewall conveyor belts are available in standard quality and in oil or grease resistant quality and with or without biased fabric. Please see our product brochure for more details on the germanWell® corrugated sidewall conveyor belt product range.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanWell® Corrugated Sidewall Conveyor Belts for Inclined Transport of Bulk Materials In inclined transport with germanWell® corrugated sidewall conveyor belts we use laterally stable conveyor belts - the germanCross basic belts. This lateral stability makes it possible to change horizontal to vertical direction of travel to vertical and vice versa. Laterally stable germanCross basic belts are available with 1 or 2 transversely rigid breakers and in strengths from 315 N/mm to up to 6000 N/mm. Just as sidewalls and cleats, germanCross basic belts are also available in highly abrasion-resistant and oil-resistant versions. We meet the customer requirements for corrugated sidewall conveyor belts. Get in touch with us.

Request for a quoteResults for

Belt transporters - Import exportNumber of results

36 ProductsCountries

Category

- Conveyor belts (11)

- Furnishings, cushioned (5)

- Conveyor systems (3)

- Packing and packaging - machinery and equipment (2)

- Goods handling systems, continuous (2)

- Mechanical engineering - custom work (1)

- Metal brushes (1)

- Package stamping machinery (1)

- Palletising machinery (1)

- Sandblasting equipment (1)

- Wood veneer - machinery and equipment (1)