- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation control

Results for

Automation control - Import export

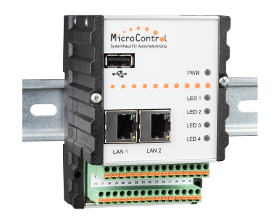

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

This pioneering controller goes far beyond the functionality of conventional PLC controllers. As an all in one IoT gateway, CANopen automation controller and top-hat rail PC, the µMIC.200 offers an end-to-end solution.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

IGUS® GMBH

Germany

- Simple automation directly using the control system without software and/or PC - Operation with limit switch or via power consumption - Left/right operation and speed control directly on the housing - Option for external switches/joysticks - Various modes of operation, such as tip operation and start to finish (semi-automatic) - Various adjustable acceleration ramps - Power supply via 24V/2.5A

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

In automation engineering, digital Controllers are used to set and stabilize the variable processes for the users pre-defined values

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

In automation engineering, digital Controllers are used to set and stabilize the variable processes for the users pre-defined values

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF CEREAL PASTE AND SUGAR BEET Lipp plans and sells storage systems for biomass such as cereal paste or sugar beet under the brand names LIGAVATOR and BETAVATOR. These systems are generally gas tight and both roof and container base (optional) are made of solid stainless steel, since the stored media can give rise to very aggressive juices and gases. With this type of storage the substances are preserved and can be used over a very long period. Automatic withdrawal and substrate delivery can also be installed in the following systems by an appropriate control system. APPLICATION EXAMPLES AND REFERENCES In addition to pure crop storage, the Lipp LIGAVATOR / BETAVATOR systems are mainly used as substrate storage for agricultural or industrial biogas plants, and are installed before the fermenter for appropriate substrate supply. They allow largely automated control of a biogas plant, as there is no need for a regular manual substrate supply.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing systems DOS: Perfectly controlled oil feed rates Thanks to automated control of the oil feed rate DOS series dosing systems offer the highest levels of efficiency and flexibility in your lubrication processes – and it does not matter if continuous lubrication is desired or just a single drop is required. The machine cycle time determines the interval at which the lubrication valves open. The following DOS dosing systems are available from us: DOS 10 MR, DOS 10 MR H: system for pneumatically operated roller lubricators WF 60 WG, WF 110 WG, WF 110 MOT. Optionally available with poppet valve DOS 40: reservoir and control unit are separate. Also available for squeeze-on lubricators, but without pressure vessel (replacement: VB 10). DOS S: version for sector lubrication; in this case the oil feed for each roller can be programmed separately (via PLC). Other configurations include, amongst others, an extension to facilitate oil supply directly from an oil drum or an option to operate

Request for a quote

CRYOSNOW GMBH

Germany

• Control cabinet with process control, inspection and monitoring for automated applications • Integrated control and safety components • Simple, ergonomic operation • For use with stationary CO2 tank (or bundles) • Modular construction, design according to customer requirements

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA shows you different ways to reduce product rejects: Increase the automation level: If the level of automation gets increased, human errors are reduced, thus avoiding rejects (e.g. digital order processing, automated quality control, immediate error messages by email, SMS, etc.). Analyse production processes: Rethink your production processes in order to increase the product usability (e.g. hardener dosing directly at the consumer). Remove contaminants: Eliminate contamination from the use of the final products.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

High-tech system for maximum process reliability. Automatic nozzle SDA 30: high-tech system for maximum process reliability The SDA 30 is an integrated system consisting of a nozzle and a control module. The nozzle is equipped with a Hall sensor that monitors and controls the position of the nozzle needle. All operational settings/adjustments (oil rate and so forth) are automated via the controller of the proprietary Eckardt control unit. This makes it possible to control up to four nozzles at the same time.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

CODESYS Control Runtime is the leading manufacturer-independent programming system according to IEC 61131-3. Programmable Logic Controllers (PLCs), ECUs / mobile controllers, visualization devices, motion controllers and additional automation devices in various industries are programmed with this automation software. The CODESYS runtime is implemented on the control platforms of Kendrion Kuhnke and can therefore be used immediately for the machine builder. Continuously improvements are being made to the programming system and enable users to continue to innovate in the future.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Error proofing for SLTC-FM preset click wrenches. The Torque Control Verifier (TCV) is ideal when the application calls for accuracy, repeatability and simplicity of the 2.4 GHz Wireless Preset Clicker-Type Torque Wrench, and only a single tool at the station needs to be controlled. The TCV-FM provides verification to the operator on the quality of each use, plus DC 24V relays and I/O port for line controller communications (PLC). The TCV-FM was created for those who desire to integrate their manual torque wrenches into their control line automation, without necessarily needing all of the features of the PTV-FM. The TCV performs the comparison and communication functions required for basic control, but without the stand-alone capabilities of the PTV.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Together with our customers, we develop scalable control and automation solutions for their assembly, laser and ECM lines to meet their requirements. In doing so, we attach great importance to the topicality and future-proof development of the technology used. Programming under SIEMENS SPS, SIEMENS NC, BECKHOFF HMI and robot technology are our specialties. We are experts in realization drive and feedback control engineering, electrical project planning, control-cabinet construction, software development and control engineering.

Request for a quote

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The weigh price labeller GLM-Ievo intelligently designed for automatic weighing and labelling of pre-packaged goods comes in different versions. The Weigh Price Goods Labelling System GLM-Ievo 170 will achieve over 170 packs per minute. Due to its modular design, it can be optimally configured for alternative products and offers exemplary performance requirements in the food production area. Thanks to the modular system of the weigh price labeller, there are no limits for todays and any future requirements you may have in the industrial food area. Besides its flexibility, this labelling system stands out in terms of robustness and an easy-to-clean design. With intelligent visual quality control and automated activation of process data via the new function Plug-In® Label operation it is easy to maintain and manage thereby reducing errors during the packaging...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENDRION KUHNKE AUTOMATION GMBH

Germany

Kendrion Kuhnke Automation relies on CODESYS as a software platform for a wide variety of applications in the automation industry. For all Kuhnke platforms, this software is available as release CODESYS V3. The IEC 61131-3 programming system offers IEC 61131-3 editors (FBD, LD, IL, ST, SFC), comprehensive debugging and online functions to optimise the application code, as well as fieldbus configurators and editors to generate visualisations. Single and multi-axis motion control all the way to the writing of curves can be projected within the well-known IEC 61131-3 development platform together with all related logic applications. Summing it up it can be said that the tool offers the user an integrated solution to support him in his everyday work and is tailored to offer real-life support to accomplish his tasks. ; EC 61131-3 programming tool for industrial control and automation technology; Integrated visualisation editor; Numerous security features (source code, communication, ...)

Request for a quote

CRYOSNOW GMBH

Germany

• For automized applications • CO2 consumption is controlled by pressure and temperature • Compact design, overall length 134 mm (5.3") • Customer-specific robot adapter • Weight without robot adapter 3.9 kg (8.7 lb) • No water condensation due to high efficient thermal insulation • Process reliable and maintenance-free in permanent operation • Cleaning width 200 mm (7.8")

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

Real-time Linux, Ethernet, CAN, USB plus custom electronics in a space-saving metal top-hat rail casing. In its µMIC.200 family, MicroControl integrates the best of the world of automation for IoT/Industry 4.0. The unit is equipped with COMBICON® connectors and offers versatile connection facilities for digital signals, CAN bus and RS-232. I/O modules with CAN interface can be connected to the unit via the integrated CANopen FD Master library. An even higher flexibility is offered through its customizable electronics. Two boards perfectly matched. CPU board and high performance standard board or – alternatively – a CPU board and a custom board tailored to your specific needs. The metal casing is able to withstand extreme operating environments. And all this at most favourable terms.2 Ethernet interfaces 2 CAN interfaces (isolated) 2 x RS-232 (isolated) CANopen Master function Cortex-A8 CPU with USB interface of 1 GHz frequency 4 GByte Flash and 512 MByte DDR3 RAM

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

The industrial CPUs from AIS Hensch Automation-Industry-Solution represent a first-class solution for controlling automated production processes in various industrial sectors. These CPUs are characterized by their technological excellence, reliability and versatility, making them an indispensable component for optimizing manufacturing processes. Thanks to their powerful processing, our industrial CPUs offer precise control that can be seamlessly integrated into a wide variety of production environments. From the oil and gas industry to mechanical engineering, these CPUs flexibly adapt to the specific requirements of different industries. The robustness and longevity of our industrial CPUs ensure reliable performance even under demanding conditions.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The MPERIA marking and coding automation platform centralizes control of your marking technology, regardless of equipment technology or vendor

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The MPERIA marking and coding automation platform centralizes control of your marking technology, regardless of equipment technology or vendor.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the convenient operation of steam boilers up to 4,000 kg/h of steam — Appealing price-performance ratio for steam boilers up to 4,000 kg/h of steam — Colour touch display for easy operation and clear visualisation of operating status — Flexible installation and small space requirement: installed on the boiler at the factory or loose control cabinet for wall mounting — Power electronics for fuel supply, feed water pump, blow-down and desalting — Optional: fully automated and conductivity-controlled blow-down and desalting

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 1436 cPos is a digital electro-pneumatic positioner with optionally integrated process controller for the control of pneumatically operated process valves. When using the optional process controller the signals from a process sensor (e.g. flow, level, pressure, temperature) are detected and the media adjusted according to the specified set value. The positioner has a solid housing with protected operating buttons and a LC display. —Digital inputs (option) for variable function control for automation —Fieldbus interfaces e.g. Profibus DP, DeviceNet (option) —No air consumption when idle —Simple mounting to various valve actuators —Access rights via different user levels

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ThermoView TV30 thermal imaging camera provides a rich feature set of automation and control capabilities along with the expected durability to meet the demanding industrial applications that FPI product need to survive in. TV30 can interface directly to factory automation equipment, 3rd party software such as Labview, or Fluke Process Instruments ThermoView software. By incorporating a built-in I/O for automation applications in a small foot print, you can expand your field of view by providing continuous infrared images, recording, and actionable analytics right at your fingertips. To meet the factory automation needs of today, TV30 cameras utilize edge technology to provide analytics calculations and on board I/O, multiple fieldbus protocol capabilities to interface to a variety of factory automation equipment, along with high-speed GigE vision capability for the most demanding applications.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quoteResults for

Automation control - Import exportNumber of results

62 ProductsCountries

- Germany (62)

- Berlin and region (4)

- Bonn, Düsseldorf and North Rhine and Westphalia (11)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (1)

- Hannover and Lower Saxony (4)

- Kiel and Schleswig-Holstein (3)

- Leipzig and Saxony (1)

- Munich, Nuremberg and Bavaria (13)

- Stuttgart, Freiburg and Baden-Wurtemberg (19)

- Weimar and Thuringia (3)

Category

- Water extraction - systems and equipment (4)

- Connectors, electronic (3)

- Internal transport systems (3)

- Magnetic equipment (3)

- Electronic data processing - microcomputers (2)

- Measurement - Equipment & Instruments (2)

- Precision measuring instruments (2)

- Printers - computer (2)

- Valves for pneumatic equipment (2)

- Automation - systems and equipment (1)

- Electrical & Electronic Components (1)

- Food Industry - Machines & Equipment (1)

- Industrial valves, operating equipment (1)

- 3D software (1)

- Blast cleaning equipment (1)

- Boilers, industrial (1)

- Construction - Machines & Equipment (1)

- Data analysis (1)

- Disks, magnetic (1)

- Electrical engineering - portable power tools (1)