- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation control

Results for

Automation control - Import export

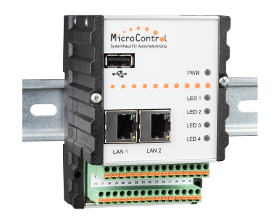

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

This pioneering controller goes far beyond the functionality of conventional PLC controllers. As an all in one IoT gateway, CANopen automation controller and top-hat rail PC, the µMIC.200 offers an end-to-end solution.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

IGUS® GMBH

Germany

- Simple automation directly using the control system without software and/or PC - Operation with limit switch or via power consumption - Left/right operation and speed control directly on the housing - Option for external switches/joysticks - Various modes of operation, such as tip operation and start to finish (semi-automatic) - Various adjustable acceleration ramps - Power supply via 24V/2.5A

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

Real-time Linux, Ethernet, CAN, USB plus custom electronics in a space-saving metal top-hat rail casing. In its µMIC.200 family, MicroControl integrates the best of the world of automation for IoT/Industry 4.0. The unit is equipped with COMBICON® connectors and offers versatile connection facilities for digital signals, CAN bus and RS-232. I/O modules with CAN interface can be connected to the unit via the integrated CANopen FD Master library. An even higher flexibility is offered through its customizable electronics. Two boards perfectly matched. CPU board and high performance standard board or – alternatively – a CPU board and a custom board tailored to your specific needs. The metal casing is able to withstand extreme operating environments. And all this at most favourable terms.2 Ethernet interfaces 2 CAN interfaces (isolated) 2 x RS-232 (isolated) CANopen Master function Cortex-A8 CPU with USB interface of 1 GHz frequency 4 GByte Flash and 512 MByte DDR3 RAM

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

OGE GROUP

Germany

Automation and Control Engineering

Request for a quote

EC AUTOMATIC GROUP-GERMANY GMBH

Germany

Our company provides a full range of services for the development and implementation of automated process control systems for industrial enterprises. We are ready to help with the design, modernization, start-up and maintenance of various production lines or individual units of technological processes. 1423 engineering projects have been completed in close cooperation with the technologists and design teams of our clients. We automate existing production facilities, participate in the development and installation of facilities under construction, supply equipment and carry out commissioning, perform further technical and service maintenance. For today, our team is more than 150 people: engineers, managers, equipment installation and maintenance specialists. Be assured – we will carefully study your tasks and provide the best solutions.

Request for a quoteResults for

Automation control - Import exportNumber of results

11 Products