- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transfer of machines

Results for

Transfer of machines - Import export

FEMIA INDUSTRIE

France

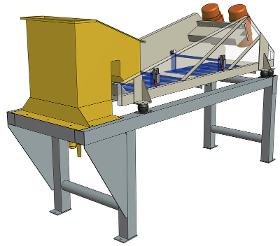

The conveyor provides the product transfer to the machine located downstream. The distributor evenly and continuously transfers your products to several machines downstream. Several outlets and fully adjustable deflector flaps guarantee ideal distribution of your products between the various outlets. Can be adapted and customised according to your needs and capacities (length, width, number of outputs).

Request for a quote

NORELEM FRANCE

France

Metal parts, steel grade 5.6. Elastomer, natural rubber, medium hardness, Shore 60. Version: Steel electro zinc-plated. Note: These machine feet have proven themselves to be universally applicable elements for the elastic support of all types of machine. They are commonly used wherever large horizontal movements are to be avoided. The horizontal rigidity is higher in all directions than the vertical rigidity. If used correctly they are excellent at preventing the transfer of vibration and noise. Machine feet with shear protection are available for situations where tensile forces are to be expected. The indicated load data are reference values for static loads by rubber hardness of Shore 60A. In contrast to those in the drawing, the holes D2 can also be elongated holes.

Request for a quote

NORELEM FRANCE

France

Steel, housing plastic, adhesive anchor steel. Note: Suitable for adjustment loads up to 12 tonnes. The heavy-duty anchors apply the centre double wedge principle. With the centre double wedge principle, the machine support height is adjusted by two wedges instead of one. The wedge movements are consistent and free of play. With the double wedge, the force acting on the lifting mechanism is halved and the central support point always remains rigid and stable. The spherical machine support on rounded discs can compensate for unevenness in the floor. Horizontal movements are prevented by the centring sleeve which holds the floor bolt in the form of an adhesive anchor. Application: Example applications of the levelling wedge are for levelling heavy machine tools, high-speed milling machines, and transfer machines

Request for a quote

MICROCERTEC

France

This technology was implemented as part of a transfer of technology from ONERA – National Laboratory for Aerospace Research – who developed it for its own needs. The technology contributed amongst other things to the manufacturing of electrode plates in silica for space accelerometers – GOCE project from ESA. Principle The principle is based on an electrical current – at a given frequency that fits within the field of ultrasounds –converted into a mechanical vibration that is transferred to a machining tool. The vibration frequency of the tool corresponds to the frequency of the electrical signal – in this case 20 KHZ. Our ultrasonic machining process differentiates itself from other processes because machining is carried out without contact between the tool and the part. Equipment A resonating block made up of piezoelectric ceramics transfers the vibration to the tool through the sonotrode. The mechanical expansion of the tool – so-called tool elongation – can be adjusted and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Transfer of machines - Import exportNumber of results

4 Products