- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transfer of machines

Results for

Transfer of machines - Import export

STARRAG GMBH

Germany

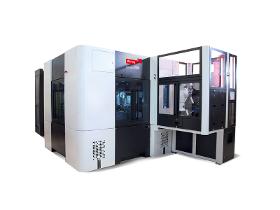

A 4station transfer machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g 4 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quote

IMOBERDORF AG

Switzerland

The imo-smart is a highly-flexible, versatile rotary transfer system. 4 to 16 machining stations with up to 22 or more spindles ensure fastest setup times. The imo-smart provides you with a ready-to-use machining solution, tailored to your specific requirements and with a wide range of applications. The parts feed is carried out from bar stock, by means of load handling, robot or manually. With a reproducibility of ± 0.003 millimetres, the imo-smart is one of the most precise rotary transfer machines in the world. The imo-smart is designed to be a highly flexible and versatile solution. The excellent accessibility allows adjustments to be made in record time. The 3-axis E-80-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-compact and the imo-space

Request for a quote

IMOBERDORF AG

Switzerland

Due to their flexible construction and virtually unlimited machining variants, Imoberdorf rotary transfer systems are suitable for the manufacture of the most diverse small and miniature parts. Please contact us − we are glad to help you identify the opportunities that will be opened up for you with an Imoberdorf rotary transfer system.

Request for a quote

IMOBERDORF AG

Switzerland

On an area of only 9 square metres at a height of 2.30 metres, the imo-compact unites to form a complete, highly-productive rotary transfer system: The imo-compact controls 4 to 8 machining stations with up to 14 spindles per CNC. The parts feed is carried out optionally from bar stock, by means of load handling, robot or manually. The reproducibility of ± 0.003 millimetres makes the imo-compact one of the most precise rotary transfer machines in the world. The imo-compact unites all the elements of a rotary transfer machine. Even the smallest platform offers optimum accessibility. The 3-axis E-97-CNC unit meets the most common needs: drilling, milling, reaming and tapping. It can be equipped with two spindles and installed horizontally or vertically. This unit can also be used on the imo-smart and the imo-space The imo-rot corresponds to the 4th axis: the C-axis

Request for a quote

FEMIA INDUSTRIE

France

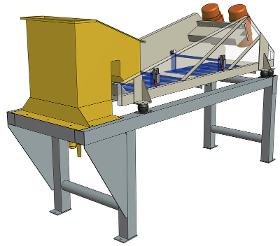

The conveyor provides the product transfer to the machine located downstream. The distributor evenly and continuously transfers your products to several machines downstream. Several outlets and fully adjustable deflector flaps guarantee ideal distribution of your products between the various outlets. Can be adapted and customised according to your needs and capacities (length, width, number of outputs).

Request for a quote

DEKORTECH GMBH

Germany

Discover the TURBOTRAN 6.1, the fully automatic heat transfer machine for textile printing with up to 600 pcs./hour. ✔ Efficiency and speed: The machine does it all, from transfer placement to pressing, peeling and giving out the finished textile ✔ Reliable support: Dedicated service team by phone, email or on-site. ✔ Features: Automatic start, a panic button, membrane platens, laser guides, and more This fully automatic heat transfer carousel is the most modern heat press in the market. With 1 operator you can decorate up to 600 t-shirts per hour. Even the application of several transfers at once is possible. The easy to change platens come in any size you need. The TURBOTRAN can be used to apply any kind of transfer but works best with hot peel DTF or screen-printed ones. An outfeed conveyor belt allows an easy integration into your process. Speed up your textile printing business for work wear, sportswear, t-shirts, hoodies, bags and more.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for PP plastics - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Adhere to untreated Polypropylene ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. These unique transfers are finished to adhere to untreated PP plastics and make them easy to use for cosmetics, promotional products, and other applications. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for packaging applications - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Adhere to many materials ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. With a range of adhesives, these transfers can be produced to stick to PP, ABS, paper, glass, ceramics, varnishes, Tritan and many other materials. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

HOCHRAINER GMBH

Germany

Different systems can achieve the objective depending on product requirements: Machine tools for type VSMH rotary transfer machining (hydraulic) Machine tool for type VSMK rotary transfer machining (cam-controlled) Type NBM finishing machines for stamped, moulded, and cold extruded parts Our years of experience in complete machining of serial parts passes to the next generation in constructive and innovative cooperation.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for beauty and cosmetic packaging - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Easy to apply ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. Make use of this product for your beauty and cosmetic primary packaging. From cosmetic tubes to airless dispensers or mascara bottles. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for pens & pencils - printed roll to roll. ✔ No MOQ ✔ For all materials ✔ Easy to apply ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. These transfers are made to adhere to a range of pens and pencils. From plain wood to coated pencils up to PP and ABS pen barrels. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

NORELEM FRANCE

France

Metal parts, steel grade 5.6. Elastomer, natural rubber, medium hardness, Shore 60. Version: Steel electro zinc-plated. Note: These machine feet have proven themselves to be universally applicable elements for the elastic support of all types of machine. They are commonly used wherever large horizontal movements are to be avoided. The horizontal rigidity is higher in all directions than the vertical rigidity. If used correctly they are excellent at preventing the transfer of vibration and noise. Machine feet with shear protection are available for situations where tensile forces are to be expected. The indicated load data are reference values for static loads by rubber hardness of Shore 60A. In contrast to those in the drawing, the holes D2 can also be elongated holes.

Request for a quote

NORELEM FRANCE

France

Steel, housing plastic, adhesive anchor steel. Note: Suitable for adjustment loads up to 12 tonnes. The heavy-duty anchors apply the centre double wedge principle. With the centre double wedge principle, the machine support height is adjusted by two wedges instead of one. The wedge movements are consistent and free of play. With the double wedge, the force acting on the lifting mechanism is halved and the central support point always remains rigid and stable. The spherical machine support on rounded discs can compensate for unevenness in the floor. Horizontal movements are prevented by the centring sleeve which holds the floor bolt in the form of an adhesive anchor. Application: Example applications of the levelling wedge are for levelling heavy machine tools, high-speed milling machines, and transfer machines

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Roller bearings support and guide rotating or oscillating machine elements such as shafts, axles or wheels and transfer loads between machine components. They provide high precision and low friction and therefore allow high rotation speeds while reducing noise, heat, energy consumption and wear. Roller bearings are cost-effective and replaceable machine elements that generally comply with national or international dimensional standards.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNELL SPA

Italy

Automatic plant for the production of calendered bars from Ø 12mm to Ø 40mm. The bars are automatically selected, positioned, transferred to the calendering machine, calendered and then unloaded without the need for operator intervention. The calendering center COMPASS 40 guarantees the insertion of the bars always oriented in the same way; automatic control of the bending radius; an automatic manufacturing process; greater safety for the operator. COMPASS 40 can operate in 3 ways Automatic with single bar it allows automatic feeding of the bar and electronic check of the produced bar bending radius; Automatic with multiple bars it allows the automatic feeding of the bars without checking the bending radius; Manual with the same features of a CER40 calendering machine. Bars calendering is mainly used in the construction of foundations for wind turbines or tunnels (those not made with prefabricated elements).

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Solcut QLB2 is a versatile solution suitable for a broad spectrum of applications. Whether you’re engaged in brass and aluminum machining within large transfer systems or tackling steel machining in smaller, single sump machines, Solcut QLB2 has you covered. This semi-synthetic biostable machining and grinding fluid forms transparent emulsions, which can become semi-translucent when used with hard water. Solcut QLB2 brings together the cleanliness and detergency typically associated with synthetic products while avoiding the sticky residues often encountered with such alternatives. It’s a reliable choice for various machining operations.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Accumulator, the transfer machine is a device that plays an important role in the production processes of toilet paper and kitchen towel rolls, increasing the efficiency of production lines. This equipment automates the storage, sorting and dispatching of rolls, ensuring that the production process is uninterrupted and orderly. This device which is widely used in modern toilet paper production facilities, significantly increases the efficiency of the production line and product quality. The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process. This accumulator is designed to prevent possible disruptions in the production line and to ensure a continuous production flow. It facilitates the organised processing and packaging of the rolls in the production process and allows the glue to dry before the rolls are cut to the desired size.

Request for a quote

FORMEX MAQUINARIA

Spain

• Provide precise positioning and centring of the mould for dosing operations. • Easy loader loading without interrupting production. • The same capping machine can be used for several types of paper/moulds with an easy and fast magazine change. • If the customer has, or is installing, an automatic dosing line, we can design the machine around the conveyor system ready for docking. • For when you want to get rid of tray transfer and paper placement. • The machine's on-board computer monitors all movements and functions such as: o Can feed. o Tray detection when placing paper. o Independent feeding function. o Parameter adjustment: - Type of suction. - Type of paper cassette. - Tray centring. - Speed regulation. • To achieve a higher degree of automation, a tray loader module can be included.

Request for a quote

ACEMAL NV

Belgium

The automatic line allows an automatic cooking for all kind of pastry. Our equipments deal with all of the industry’s stages from the pastry to the cooling of the product. Our production lines are made of the following elements: Automatic line for Liege waffle : - a divider, - a fermentation chamber, - a machine for transferring automatically the lumps of paste in the irons, - the oven, - a robot for the removal of waffles after the cooking, - cooling bands. Automatic line for all kind of products : - divider/injector, - the oven, - a removal system, - cooling bands. Every production line is adapted to the customers’ needs.

Request for a quote

ISIM GELISIYOR CONSULTANCY

Turkey

CLICHE HOT STAMPING PRESS, DTF PRINTING SYSTEMS, SCREEN PRINTING

Request for a quote

OMNITRACK

United Kingdom

Our Medium Duty ball transfer units are machined from solid steel bar which is heat-treated to provide a hemispherical wear-resistant chamber within which the recirculating balls can support the protruding, load-bearing main ball. This robust, low-noise design is engineered for applications requiring conventional (ball ‘up’) orientation. Additional options for this range include impact-absorbing top cap options, and additional drain channels where required, making these transfer units the air cargo industry standard.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5106 combined the advantage of the GWE 5104 Servo-Insert Coupling with an easy installation. The clamping hubs in split hub design can be mounted lateral at the aligned shaft extensions. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5106 Servo-insert coupling with clamping hubs in split hub design Characteristics Hubs made of aluminum, from size 55 made of steel Standard elastomeric spider with 98° A...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5107 is a compact designed backlash-free Servo-Insert Coupling with an expanding clamp and a clamping hub. Due to the expanding clamp the GWE 5107 can used for examples in hollow shafts. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5107 Servo-insert couplings with clamping hubs and expanding clamps Characteristics Hubs made of aluminum Expanding mandrel and inner cone made of steel Elastomeric spider...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

GERWAH's Servo-Insert Couplings from the production series 'GWE 5103.1' impress with their compact design. The compensating elements are slotted once and mounted by means of a clamping hub. GWE 5103.1 couplings are electrically insulating, installation-friendly and absolutely fail-safe. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5103.1 Miniature servo-insert Coupling with clamping hubs and single...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5103 Servo-Insert Coupling impresses with their compact design and a reduced moment of inertia. Due to the elastomeric spider the GWE 5103 is backlash-free, vibration-damping and electrically insulating. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5103 Servo-insert couplings with clamping hubs, short length and single slit Characteristics Hubs made of aluminum Elastomeric spider sizes 7 and 9 with...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

GWE 5102 miniature is a compact miniature coupling constituting the perfect solution for confined spaces or areas which are difficult to access. The element is connected to the shaft by means of radial set screws instead of a clamping hub. The coupling is available with elastomeric spiders of different degrees of shore hardness. But regardless of the chosen features: GWE 5102 miniature is always electrically insulating and vibration-damping. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying...

Request for a quoteResults for

Transfer of machines - Import exportNumber of results

48 ProductsCountries

Category

- Metals - Machines & Equipment (6)

- Silk-screen printing (5)

- Food industry - machinery and equipment (3)

- Embossing machine tools (2)

- Machine tools, metal machining - parts and accessories (2)

- SMALL METAL PARTS (2)

- Accumulators and batteries (1)

- Battery chargers (1)

- Cakes and pastries, factory-baked (1)

- Cheese-making machinery (1)

- Confectionery - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Conveyor systems (1)

- Foundries, aluminium (1)

- Goods handling systems, continuous (1)

- Greases, industrial (1)

- Import-export - mechanical engineering (1)

- Industrial cutting machine tools (1)

- Machine tools, cutting - parts and accessories (1)

- Marking - diverse products (1)