- europages

- >

- MICROCERTEC

- >

- Ultrasonic machining

Ultrasonic machining

Description

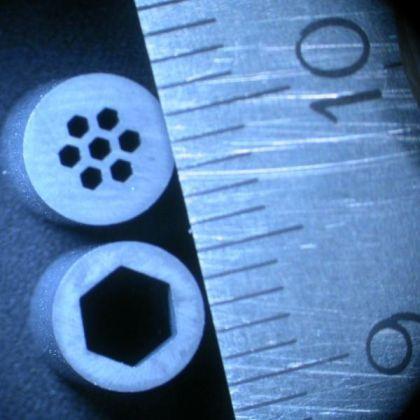

This technology was implemented as part of a transfer of technology from ONERA – National Laboratory for Aerospace Research – who developed it for its own needs. The technology contributed amongst other things to the manufacturing of electrode plates in silica for space accelerometers – GOCE project from ESA. Principle The principle is based on an electrical current – at a given frequency that fits within the field of ultrasounds –converted into a mechanical vibration that is transferred to a machining tool. The vibration frequency of the tool corresponds to the frequency of the electrical signal – in this case 20 KHZ. Our ultrasonic machining process differentiates itself from other processes because machining is carried out without contact between the tool and the part. Equipment A resonating block made up of piezoelectric ceramics transfers the vibration to the tool through the sonotrode. The mechanical expansion of the tool – so-called tool elongation – can be adjusted and...

Documents

Similar products

AMBER ELECTROMECHANIC

Turkey

18UT ProD model 18 litre Ultrasonic Cleaning Machine is microprocessor controlled and has automatic memory. It has internal heaters and is controlled by digital panel. It is your biggest helper in cleaning difficult dirt with its reinforced ultrasonic cleaning performance. As a desktop model, 18UT ProD is easy to use and easy to carry. Areas of Use Hospital Equipment Surgical Instruments Veterinary Surgeons Disinfection Applications Laboratories Optical Sector Pharmaceutical Industry Hairdressers and Barbers

Request for a quote

BRIO ULTRASONICS

Spain

Manual ultrasonic cleaning equipment with a capacity of 150 L. Exclusive BRIO technology three times more efficient than conventional systems. MANUAL Series Manual ultrasonic cleaning machines that optimise time and consumption. Composed of a simple and efficient control panel, with general switch, safety button, digital thermostat with temperature control and buttons to activate heating and ultrasound. They also have a manual work basket made up of a stainless steel tray that protects the bottom of the tank and in which the objects to be cleaned are placed inside the main tank. Robust construction with high thickness and AISI 304/316 stainless steel. Available from 60L to 7500L to cover all the needs of each sector.

Request for a quote

LOUISON INDUSTRIES

France

Industrial fabric cutting process Louison Industries offers custom cutting and cutting of textile fabrics produced by us. We offer made-to-measure industrial textile cutting for a wide variety of textiles. Whether for composite materials, reinforced technical fabrics or special textiles, our tailor-made approach guarantees professional-quality results that perfectly meet the specific needs of each project. Our industrial textile cutting skills encompass three main techniques: - Hot cutting - Cold cutting - Ultrasonic cutting We can produce a professional quality cut, adapted to the composition of the chosen textile, for all materials, small and large widths, from 10 to 1600 mm. The idea is to provide you with a finished product that can be used straight away.

Request for a quote

ATS-TANNER BANDING SYSTEMS AG

Switzerland

Energieeffiziente und produktschonende Banderoliermaschinen mit UltraschallKaltverschweissung für Banderolen aus Papier und Folie.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free