- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- emergency stop

Results for

Emergency stop - Import export

LIVAN PLEKSI

Turkey

For futher details, please contact us and visit our website

Request for a quote

BERNSTEIN AG

Germany

Whether on the conveyor belt or on the machine – when maximum safety is required, BERNSTEIN rope pull switches provide a proven and reliable technical solution.The switches can be deployed flexibly, are easy to install and convenient to handle.And most importantly: they offer maximum safety when it is needed. The SR series of safety rope pull switching devices are designed and approved in accordance with the standards IEC 947-5-5, DIN EN 60947-5-5 and ISO 13850. On actuation or in the event of cable breakage, the emergency stop switching device locks automatically and can only be reset to its initial setting by using the resetting device on the switch. • Protection class IP67 • Stable and durable plastic housing (PA 6 GV) • Can be deployed at temperatures between –25 °C and +70 °C • Flexible handling with three M20 x 1.5 cable entries • Easy installation due to the maximum connection space • Up to four positively driven NC contacts

Request for a quote

BERNSTEIN AG

Germany

BERNSTEIN AG manufactured SR and SRM safety cable pulling switch devices as per IEC 947-5-5, DIN EN 60947-5-5 and ISO 13850 standards. These technical demand that when 'actuation' or the act of the breakage of the cable, there is automatic lock out as the switch moves to stop position, and reset for further use.

Request for a quote

BERNSTEIN AG

Germany

When it comes to maximum safety on the assembly line, in the production line, or directly at the machine, the Safety Rope Pull Switches from BERNSTEIN AG are a reliable and proven solution. BERNSTEIN has added a particularly small and compact version to the product family of safety rope pull switches. Thanks to its modular design, the SRO (Safety Rope Pull) is extremely space-saving as well as being highly versatile. The modular principle has the advantage of always being able to offer exactly the right product for a specific customer application.

Request for a quote

BERNSTEIN AG

Germany

Unlike standard suspension system solutions with individual screens or IPCs, the CS-4000 neXt meets the requirements of the Machinery Directive by the possibility of integrating emergency stop devices. Due to its two-chamber design and clever construction, an IP65 solution can be achieved. • Flexible concept as console or column configuration • High protection class IP65 at area of closed column chamber • Internal cable routing • IPC and keyboard shelf holder can be positioned individually • IPC holder with graduated tilt control • Optional integrated control elements (to fulfil the Machine Directive 2006/42/EG) • Column of high-quality extruded aluminium sections (naturally anodised, 2-chamber column) • Customer-specific length of the column possible

Request for a quote

BELGOMILK IA SA

Greece

Total width 600mm Total length 500mm Guides latéraux réglables en acier inoxydable, Central Operation Panel, start – stop – emergence Central Operation Panel, start – stop – emergence Capability for dosage adjustment up to 10 liters Oil storage tank and float controlled transfer pump with ballcock Connection with the factory CIP

Request for a quote

EC PLAZA

South Korea

The elevator emergency stop device is a device that automatically operates and safely stops the elevator when an emergency occurs inside or outside the elevator. This device is an essential part to protect the safety of life and property, and is one of the devices that must be installed compulsorily in the elevator safety regulations. Generally, the elevator emergency stop device is attached to the elevator cable, and operates on the principle of automatically stopping the elevator by detecting when the cable moves at a rapid speed. This is controlled by a control device installed inside the elevator, which stops the elevator and opens the door to allow passengers to escape. Donggwang Sau provides safe and reliable elevator emergency stop devices using the latest technology and equipment, contributing to the safety and development of the elevator industry.

Request for a quoteSTÄHLE GMBH

Germany

Safety switch for detection of un-usual motions of vehicles on chassis dynamometer. Integration into local Quick stop and emergency stop loops. A safety switch which is sensitive in push, pull, vertical and horizontal excitations, mounted to a flexible arm on a solid base plate, is simply placed closed to the vehicle. Potential free NO and NC contacts. Different versions with different fixture sizes can be offered.

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Some key features of the IBC weighing filling machine may include: High-precision load cells Automatic tare and gross weighing functions Product-specific filling programs Easy-to-use touchscreen interfaces Automatic valve control for precise filling Automatic IBC positioning and clamping A range of safety features, such as emergency stop buttons and safety guarding Overall, the IBC weighing filling machine is an excellent investment for any business that requires accurate and efficient filling processes for intermediate bulk containers.

Request for a quote

NORELEM FRANCE

France

Suitable for emergency stop and continual use. Energy reduction: 25% to 45%. Dynamic force absorption: 218 N to 3730 N Impact velocity: max. 5 m/s. The profile dampers are maintenance-free and are supplied ready to install with a special fastening screw. Environment: Resistant to microbes, sea water, chemicals and with very good UV and ozone resistance. No water absorption or maceration. Application: Linear slides and linear guides, pneumatic cylinders, furniture industry, machines and plants.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The horizontal Pump Set is suitable for emptying highly aggressive, aqueous to slightly viscous media from IBC containers or tanks and is the perfect alternative to the vertical Drum Pumps. Perfectly suited for the discharge of concentrated acids and alkalis. * Optionally with leakage detection (Safety Box) * Horizontal connection at the bottom of the container Features & Advantages * Optionally with electric or compressed air drive * Low loss of medium when disconnected * Simple installation * Easy to dismantle * Small footprint * Automatic emergency stop function of the motor in case of leakage detection

Request for a quote

LUTZ PUMPEN GMBH

Germany

The horizontal Pump Set is suitable for emptying highly aggressive, aqueous to slightly viscous media from IBC containers or tanks and is the perfect alternative to the vertical Drum Pumps. Perfectly suited for the discharge of concentrated acids and alkalis. * Optionally with leakage detection (Safety Box) * Horizontal connection at the bottom of the container Features & Advantages * Optionally with electric or compressed air drive * Low loss of medium when disconnected * Simple installation * Easy to dismantle * Small footprint * Automatic emergency stop function of the motor in case of leakage detection * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic drum liquid weighing filling machines are designed to fill drums with liquids using weight sensors and speed control technology. Some of the features of these machines include: Accuracy: These machines use weight sensors to ensure the accurate and consistent filling of drums with liquids. Speed control technology: The machines are equipped with speed-control technology, which allows for the precise and efficient filling of drums with liquids. Ease of use: The machines are designed to be user-friendly, with easy-to-use controls and quick changeover times. Versatility: These machines can handle a wide range of liquids from oils, solvents, chemicals, and other high-value liquids. Safety: The machines have built-in safety features, such as emergency stop buttons and guarding, to ensure operator safety. Low maintenance: Automatic drum filling machines are often designed for low maintenance

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Accurate weighing system: This machine is equipped with a highly accurate weighing system that ensures precise filling of liquids into drums. Easy to operate: The semi-automatic filling machine is user-friendly and easy to operate. It requires minimal training for operators to handle it. High filling speed: The machine has a high filling speed that helps save time and increase productivity. Durable construction: The robust construction of the machine ensures its longevity and stability. It is made of high-grade stainless steel, which makes it resistant to corrosion. Flexible design: This semi-automatic machine is highly adaptable to different sizes and shapes of drums. It can accommodate a wide range of container sizes and volumes. Low maintenance: The machine is designed for ease of maintenance and requires minimal upkeep. The components are easily accessible for routine cleaning and maintenance. Safe and reliable: With safety features such as emergency stop buttons and door sensors

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

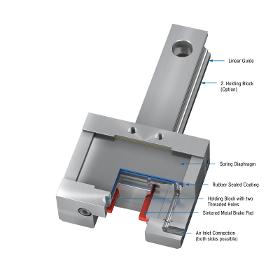

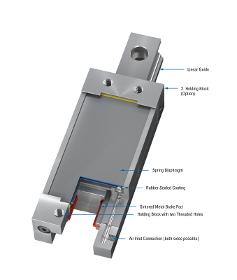

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

High Rack Damper, Optimized Characteristic Energy capacity 14,500 Nm/cycle Stroke 100 mm Intelligent protective measure: The safety shock absorbers from the SDH38 to SDH63 series are also designed for emergency-stop applications. Strokes of up to 1,200 mm are possible with these maintenance-free and ready-to-install dampers. Low support forces result due to the large strokes. The characteristic curve or damping characteristics of all safety shock absorbers from ACE is individually adjusted to the respective application, specific to the customer. The metering ori?ces for the respective application are specially calculated and produced. These tailor-made machine elements are the ideal protection because they are less expensive than industrial shock absorbers and are effective with up to 1,000 maximum full load emergency cycles possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating or Optimized Characteristic Energy capacity - Nm/cycle Stroke 48.6 mm Effective emergency stop: The ACE safety shock absorbers from the SCS33 to SCS64 product family are based on the innovative technology of the successful industrial shock absorbers from the MAGNUM-Series. They are also maintenance-free and ready-to-install. Due to the optimised characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating or Optimized Characteristic Energy capacity - Nm/cycle Stroke 23.1 mm Effective emergency stop: The ACE safety shock absorbers from the SCS33 to SCS64 product family are based on the innovative technology of the successful industrial shock absorbers from the MAGNUM-Series. They are also maintenance-free and ready-to-install. Due to the optimised characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating or Optimized Characteristic Energy capacity - Nm/cycle Stroke 23.2 mm Effective emergency stop: The ACE safety shock absorbers from the SCS33 to SCS64 product family are based on the innovative technology of the successful industrial shock absorbers from the MAGNUM-Series. They are also maintenance-free and ready-to-install. Due to the optimised characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications.

Request for a quote

NORELEM FRANCE

France

Suitable for emergency stop and continuous use Energy reduction: 58% to 73% Dynamic force absorption: 870 N to 35190 N Impact velocity: max. 5 m/s. The profile dampers are maintenance-free and are supplied ready to install with a special fastening screw. Environment: Resistant to microbes, sea water, chemicals and with very good UV and ozone resistance. No water absorption or maceration. Fastening screws: Special cap screws with hex sockets, material 44SMn28 (free-cutting steel SAE 1144) electro zinc-plated: M6x9, M6x10, M8x14, M12x18, M16x26 ISO 4762 cap screws with hex sockets - 8.8 steel, black: M3x6, M4x8**, M5x10** ** With DIN 125 washer, electro zinc-plated steel. Application: Linear slides and linear guides, pneumatic cylinders, handling equipment, machines and plants

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Robust and extremely low maintenance Optimal access All-round bundle guide Integrated safety concept ASLF 'Anti-Strap-Loss-Function' Constant strap control Pusher (bundle accelerator and bounce back function) Strap width 5 - 9 mm, adjustable Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp Additional operating buttons, opposite to terminal (Start/Stop/Emergency Stop) DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Upstream and downstream interlocks EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' OPTIONAL: Stacker adapter for existing stacker Bundle stops, no contact with bundle when clearing the bundle, with quick adjustment Bundle press Protection covers at feed and discharge side, hinged Lateral bundle guide, adjustable Side...

Request for a quote

LUTZ PUMPEN GMBH

Germany

The horizontal Pump tube is suitable for emptying highly aggressive, aqueous to slightly viscous media from IBC containers or tanks and is the perfect alternative to the vertical Drum Pumps. Perfectly suited for the discharge of concentrated acids and alkalis. * Optionally with leakage detection (Safety Box) * Horizontal connection at the bottom of the container * IBC connection: S60 x 6 Features & Advantages * Optionally with electric or compressed air drive * Low loss of medium when disconnected * Easy to install * Easy to dismantle * Small footprint * Automatic emergency stop function of the motor in case of leakage detection * The maximum flow rate is a value determined by means of a test bench and measured with water at a liquid temperature of approx. 20 °C . The measurement is taken at the pressure joint of the pump, without hose, nozzle or flow meter.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The hydraulic industrial shock absorber of the C-series (COMPENSER®) is the ideal hydraulic buffer for storage and retrieval machines or smaller conveyor systems, crane systems, test stands etc. in light to medium mechanical engineering. Due to its short design, this hydraulic buffer (COMPENSER®) can be used in a spacesaving manner as limitation of the end position (as emergency end stop) in industrial applications. In addition, the low reset force allow operational pushin cycles at creep speed. Design & Function: The piston rod 2 enters the metering tube 3. The damping medium flows from the pressure chamber 6 through the throttle orifices 4 of the metering tube 3 into the volume balance chamber 5. The nitrogen gas between the outer tube 7 and the metering tube 3 is compressed and stores the energy required for the reset of the piston rod. When the piston rod 2 returns to the initial position, the damping medium flows back into the pressure chamber 6.

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

APD MAQMASTER

Spain

350mm diameter cutting disc included. 2HP motor. 2x pneumatic pusher. Saw speed 3000 rpm. Shaft diameter 32 mm. Max cutting height 125 mm. Moveable turret to increase cutting capacity. Manual lubrication system. Manual disk upload. Cut at any angle between -45º/90º/+45º. Emergency stop. CE standards. OPTIONS Swivel cabinet/base. PACKAGING AND DIMENSIONS 480 x 780 x 850 mm (68 Kg). Standard wooden cage packaging.

Request for a quote

GRAVOTECH

France

TOUCH SCREEN Just press the touch screen and the LW2 takes care of the rest! The door closes automatically, the laser is positioned at the right focus height, the marking is done in a few seconds and the door opens. This laser station does not require training. Just prepare your marking jobs and load them into your industrial marking solution via the USB port. COMPLETE SAFETY This laser marking system is certified as class 1 laser products, allowing use in unrestricted environments: integrated fail-safe relay, protective glass, door closure security, emergency stop, door fitted with sensors and anti-pinch system, integrated extraction and filtration solution to protect users from dust and smoke. Mechanic and electronics are fully protected in a sealed box. Integrated alarms and controls. FLEXIBILITY Large marking area with 3 sided door, marking of a wide variety of parts, from small to big parts, from simple to complex shapes. The LW2 is compatible with most of our laser sources.

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

The robust and reliable multi-touch monitor is designed to meet the increased demand for machine visualisation. With its full HD widescreen and multi touch technology, it guarantees first-class user-friendliness. Thanks to the flexible support arm and VESA mounting, the monitors can be easily integrated into machines and systems, customised to the specific installation situation. The additional key module allows variable operation and can be customised, including the integration of an emergency stop function.

Request for a quote

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quoteResults for

Emergency stop - Import exportNumber of results

102 ProductsCountries

Company type

Category

- Cutting - steels and metals (6)

- Hoists and elevators, construction (6)

- Forming, rubber - machinery (4)

- Gears (4)

- Bottling and filling - machinery and equipment (3)

- Harvesting machinery and equipment (3)

- Pumps (3)

- Safety shields for machines (3)

- Switches (3)

- Alarms - security devices (2)

- Automation - systems and equipment (2)

- Conveyor systems (2)

- Embossing machine tools (2)

- Nuts and bolts (2)

- Package sealing machinery (2)

- Audio-visual - production and distribution (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Batteries (1)

- Beauty salons - equipment (1)

- Bending machine tools (1)