- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt tensioners

Results for

Belt tensioners - Import export

PARSMEGA MAKINA

Turkey

It is used for vertical transportation of wheat. It consists of two parts: lower and upper heading. Pipe length is adjusted according to the building height. The drive of the elevator is made by the reducer motor located on the upper head. The motor stand has slides and can be easily adjusted to enable shaft center adjustments. Belt tension is provided by the tensioning mechanism connected to the bearings.

Request for a quote

PARSMEGA MAKINA

Turkey

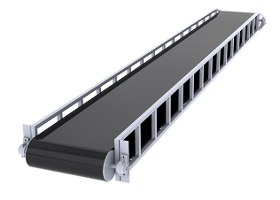

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

NORELEM FRANCE

France

The tension meter is used to perform a pretension test on commercially available belt systems quickly and easily by means of frequency measurement. Fully electronic and equipped with stateoftheart microprocessor technology, the meter enables precise adjustment of all V, toothed and flat belts that have to be tensioned in the range from 10 to 600 Hz. The measurement must never be performed while the drive is running The meter is not permitted or certified for use in potentially explosive areas.

Request for a quote

NORELEM FRANCE

France

Housing 1.4308 stainless steel, from size 5 1.4301. Clamping arm 1.4301 stainless steel. Buffer natural rubber. Screw stainless steel A2. Version Housing and lever arm bright. Screw ISO 4017, grade 70, bright. Note Clamping element with integrated highly elastic, shaperetaining natural rubber buffer. Together with a chain tensioner set, sprocket set or a tension pulley, the clamping element makes a readytoinstall tensioning unit suitable for tensioning chain and belt drives. Suitable for both tensioning directions. The clamping elements are maintenancefree and tearoff resistant. The clamping element is fastened to the machine component through a bore. If necessary, a heavyduty dowel pin can be inserted in the positioning notch “P” for torque support.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quote

HOCHRAINER GMBH

Germany

Assembly line for micro gas generator (belt tensioner) Workpiece carrier transfer system (above/below level) with multiple automation stations

Request for a quote

NORELEM FRANCE

France

Belt back and belt teeth CR. Tension cords Glascord. Tooth covering mesh polyamide. Note Endless toothed belts with an arched profile as per ISO 13050 with metric pitch. The rounded shape of the tooth contour provides a particularly high degree of safety against incorrect tooth interlocking, combined with a very rounded tooth mesh. Operating noise is significantly reduced by the rounded tooth mesh. The toothed belts are robust, economical and versatile. Belt speed vmax perm. 50 m/s Transmissible power up to 8.42 kW Permissible speed up to 14000 rpm Lownoise and lowmaintenance Very good chemical resistance, particularly against oils, greases and fuels Accurate positioning and angles

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper haul-off timing belts are made with polyurethane or neoprene timing belts that are finished with many different kinds of coatings. They are used for conveying foils in bag forming, filling and sealing machines as well as numerous other conveying tasks. The extensive range of designs offers the optimal solution for any transport task and application, e.g. with smooth or vacuum-processed surface, finished according to individual specifications, and with many different coatings. Timing belts - Polyurethane molded timing belts - or neoprene molded timing belts Tension cords - Steel - Aramid - Polyester Coatings - PU yellow - Linatex - Various elastomers - Silicone

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Increases tensile force by up to 50 % for all kinds of V-belts, round and flat belts on fans, compressors, pumps, ventilators, mills etc. Protects against drying out and wear, prevents belt squeaking and slip Advantages and benefits Increases service life Prevents squeaking Prevents slip Increases belt tension force

Request for a quote

NOVELTY STEEL

Turkey

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer. Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose. The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Request for a quote

NOVELTY STEEL

Turkey

While various idlers have been developed to perform adequately in different installations, determining the most appropriate one remains a challenging task. The primary function of an idler roll is to provide load support with minimal resistance to movement, particularly addressing radial loading from the belt and materials across specific idler spacing. This role encompasses absorbing impact at the loading point and managing belt tension in curved sections, which can be challenging to quantify. Modern conveyor design methods have enhanced our comprehension and control, providing clearer insights into idler implications. Assemblies of idler rolls are strategically designed to influence the belt profile, often forming a trough or tube. It’s essential to acknowledge that the trough’s shape, consistency, and flexibility significantly impact idler roll behaviour.

Request for a quote

KULLEN-KOTI GMBH

Germany

We can produce flat-belt brushes in any length requested, open ended or endless. They are mainly equipped with natural hairs or bristles, plant fibres or synthetic bristles. Depending on the fill material a brush surface from very soft to very hard can be obtained. As belt qualities we supply the multilayered types 5,8 mm or 7,0 mm (belt thickness) with a cover sheet and running surface made of chrome leather and an integrated polyamide insert. They are suitable for temperatures from -15°C to +80°C. When using endless closed belts, belt pre-tension is an important factor.For our types 4,8 mm to 9,5 mm we normally use a belt pre-tension of 1,5 to 2% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). Please ensure the diameters of the deflection pulleys (d) are correct in order to obtain an adequate looping of the belt. We advise you...

Request for a quote

FORBO SIEGLING GMBH

Germany

Textile Industry For decades Forbo Movement Systems has been accompanying the numerous developments in the manufacture of yarn and fabrics together with the textile machine manufacturers. The results are: Power transmission belts with thermoplastic tension members made of polyester and aramide as drive elements in yarn processing Cross-lapper belts with specially developed coatings New printing blankets for ideal printing results

Request for a quote

PIZZIRANI SRL

Italy

PCHAINS are manufactured according to the international regulation din 8187 and din 8188. They are made by top quality steel whose mechanical features are very high. During the automatized assembly the PCHAINS are put under tension to set the dimension and to avoid strain in the initial pressure. PCHAINS are lubricated in oil , packed in plastic bags and then put in cardboerd boxes. You can find in the list the most used products. We can also supply special chains upon request such as “fragmentated” and “ringclosed”. Our technical service can give yuo further information on the materials and the special treatments we are able to offer to the customer. In 6 different dimensions they are suitable for electrical motors from size 63 (kw. 0.12 – 4 poles) to size 180 (kw.22 – 4 poles). The adjustable Motor Mountings are designed to solve the problem of the belt tension in power transmission.

Request for a quote

KULLEN-KOTI GMBH

Germany

For this brush type we use standardised vee-belt profiles, made of polyester elastomers and immune to moisture, oil and grease as well as resistant to numerous chemicals. Therefore an application is possible in a temperature range from -15°C to +80°C. They can be produced in all lenghts requested, open ended or endless closed belt. Mainly natural hairs and bristles, plant fibres and synthetic bristles (PA, PP, etc.) are used, so all kinds of brush surface - from very soft to very hard - can be obtained according to the material quality chosen. For the endless vee-belt brushes you normally have to use a belt pre-tension of 3% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). You can use standardised drive pulleys to drive the belt brushes.Please ensure the diameters of the deflection pulleys are correct in order to obtain an...

Request for a quote

FERPLAST SNC

Italy

MECHANICAL/HYDRAULIC FM LIFTERS FOR FURNITURE Ideal for transporting furniture, safes, containers and machine tools. The FM series mechanical/hydraulic lifter kit for furniture is suitable for moving furniture components in furniture stores, during removals or simply when you need to move furniture safely and without any effort. The maximum load capacity of the pair is 600kg (FM60 mechanical model) and 1800kg (FM180/A - FM 180/B hydraulic models). The kit consists of 2 lifts with lifting plates with non-slip coating and a strap for fixing. Lifting is by means of a screw with crank for the FM 60 model and a practical lever with a hydraulic pump for FM 180. The lifts are equipped with non-marking pivoting rubber wheels with steering lever. RAL 1028 yellow paint for the FM 180 models and blue for the FM 60 model Operation: Position the lifting plates below the part to be lifted, adjust the upper support and tension the safety belt.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERO JOINT .TANALS

France

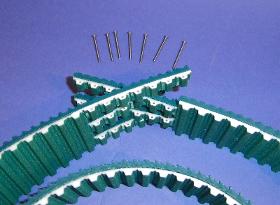

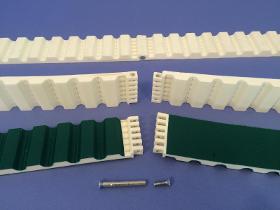

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

MAINTENANCE PARTNERS

Belgium

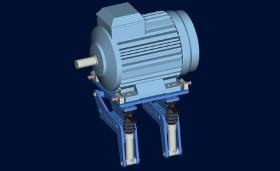

Gemex is a hydraulically adjustable and mechanically lockable motor platform, which allows technicians to check and, if necessary, to adjust the belt‘s tension in the easiest and most efficient way. In 2 minutes your belts are replaced, no realignment is needed. It will reduce your maintenance & energy costs and increase the life cycle of your equipment. Gemex Belt Tensioning System Benefits The Gemex hydraulic belt tensioning system is designed to be compatible with all designs and types of existing belt tensioning systems. The Gemex system is easy to use and comes with many benefits: Energy Savings 5 to 10% energy savings ROI of ±1 year Ease of Maintenance Improved safety for maintenance operators Belts can be adjusted during production Belt replacement within 2 minutes No alignment required Easy access and maintenance No special education necessary, everybody can use Gemex Available for all applications Installation possible on every existing frame All types of...

Request for a quote

MAINTENANCE PARTNERS

Belgium

It allows technicians to check and, if necessary, to adjust the belt‘s tension in the easiest and most efficient way. In 2 minutes your belts are replaced, no realignment is needed. It will reduce your maintenance & energy costs and increase the life cycle of your equipment. Gemex Belt Tensioning System Benefits The Gemex hydraulic belt tensioning system is designed to be compatible with all designs and types of existing belt tensioning systems. The Gemex system is easy to use and comes with many benefits: Energy Savings 5 to 10% energy savings ROI of ±1 year Ease of Maintenance Improved safety for maintenance operators Belts can be adjusted during production Belt replacement within 2 minutes No alignment required Easy access and maintenance No special education necessary, everybody can use Gemex Available for all applications Installation possible on every existing frame All types of belts Horizontal / vertical All industries that use belt applications

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The unique belt guide system allows the use of very small belt widths without the belt coming off the roller. The tensioning system ensures continual tension in the belt thus contributing to the safety of the guide system. Available in lever or rotary valve variants. Individual work through the rotatable head. Furthermore it has a protective cap for safe handling.

Request for a quote

IDEMAG

Spain

The electromagnetic separators suspended on conveyor belts are the most effective equipment for removal of ferrous contamination from other nonferrous materials. Consist of an electromagnet which creates powerful magnetic fields that are generated by electrical coils which provide the required attractive force to separate the iron pieces. The self-cleaning of the equipment is performed by a resistant rubber belt and provided with transverse projections.This facilitates the transport of material and separation of the captured contamination throwing it to one side of the conveyor. The belt is mounted on a metal frame with pulleys that rotate with its bearings and is driven by an electric motor with a speed reducer; belt tensioning is done through a deflection drum. Its main mission is the protection of crushing and grinding equipment against damage and wear caused by the presence of iron pieces.The electromagnetic overbands separate ferrous particles from other materials in recycling pr.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

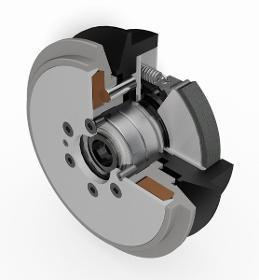

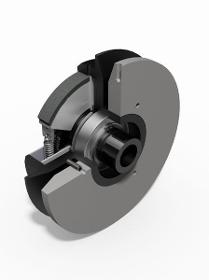

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

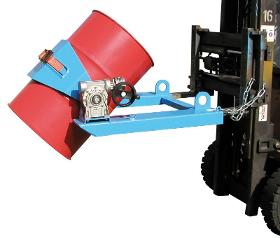

BAUER GMBH

Germany

-sturdy frame with fork sleeves -prism pick-up with tension belt and -double worm gear -can be secured to prevent slipping -load capacity 300 kg -range of rotation 360° -suitable for pick-up by a forklift truck, dumper or crane Types available -Type FLEX-HK tipping process by crank handle -Type FLEX-K tipping process by loop chain

Request for a quoteResults for

Belt tensioners - Import exportNumber of results

42 ProductsCategory

- Conveyor belts (5)

- Transmission belts (3)

- Clutches (2)

- Conveyor systems (2)

- Filtering equipment and supplies (2)

- Oils, cooking - machinery and equipment (2)

- Wood veneer - machinery and equipment (2)

- Axles, vehicle (1)

- Beverage industry - machinery and equipment (1)

- Blades for saws and cutting machines (1)

- Chains, iron and steel (1)

- Compensators (1)

- Engines & Parts (1)

- Grinding - machine tools (1)

- Handling of goods - motorized vehicles (1)

- Inductive sensors (1)

- Knives and scissors for household and professional use (1)

- Magnetic equipment (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Offshore services (1)