- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt tensioners

Results for

Belt tensioners - Import export

NORELEM FRANCE

France

The tension meter is used to perform a pretension test on commercially available belt systems quickly and easily by means of frequency measurement. Fully electronic and equipped with stateoftheart microprocessor technology, the meter enables precise adjustment of all V, toothed and flat belts that have to be tensioned in the range from 10 to 600 Hz. The measurement must never be performed while the drive is running The meter is not permitted or certified for use in potentially explosive areas.

Request for a quote

NORELEM FRANCE

France

Housing 1.4308 stainless steel, from size 5 1.4301. Clamping arm 1.4301 stainless steel. Buffer natural rubber. Screw stainless steel A2. Version Housing and lever arm bright. Screw ISO 4017, grade 70, bright. Note Clamping element with integrated highly elastic, shaperetaining natural rubber buffer. Together with a chain tensioner set, sprocket set or a tension pulley, the clamping element makes a readytoinstall tensioning unit suitable for tensioning chain and belt drives. Suitable for both tensioning directions. The clamping elements are maintenancefree and tearoff resistant. The clamping element is fastened to the machine component through a bore. If necessary, a heavyduty dowel pin can be inserted in the positioning notch “P” for torque support.

Request for a quote

NORELEM FRANCE

France

Belt back and belt teeth CR. Tension cords Glascord. Tooth covering mesh polyamide. Note Endless toothed belts with an arched profile as per ISO 13050 with metric pitch. The rounded shape of the tooth contour provides a particularly high degree of safety against incorrect tooth interlocking, combined with a very rounded tooth mesh. Operating noise is significantly reduced by the rounded tooth mesh. The toothed belts are robust, economical and versatile. Belt speed vmax perm. 50 m/s Transmissible power up to 8.42 kW Permissible speed up to 14000 rpm Lownoise and lowmaintenance Very good chemical resistance, particularly against oils, greases and fuels Accurate positioning and angles

Request for a quote

ERO JOINT .TANALS

France

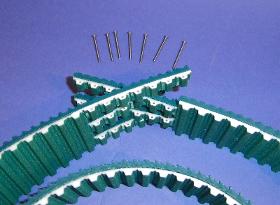

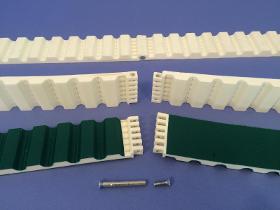

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Belt tensioners - Import exportNumber of results

6 Products