- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt tensioners

Results for

Belt tensioners - Import export

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quote

HOCHRAINER GMBH

Germany

Assembly line for micro gas generator (belt tensioner) Workpiece carrier transfer system (above/below level) with multiple automation stations

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper haul-off timing belts are made with polyurethane or neoprene timing belts that are finished with many different kinds of coatings. They are used for conveying foils in bag forming, filling and sealing machines as well as numerous other conveying tasks. The extensive range of designs offers the optimal solution for any transport task and application, e.g. with smooth or vacuum-processed surface, finished according to individual specifications, and with many different coatings. Timing belts - Polyurethane molded timing belts - or neoprene molded timing belts Tension cords - Steel - Aramid - Polyester Coatings - PU yellow - Linatex - Various elastomers - Silicone

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Increases tensile force by up to 50 % for all kinds of V-belts, round and flat belts on fans, compressors, pumps, ventilators, mills etc. Protects against drying out and wear, prevents belt squeaking and slip Advantages and benefits Increases service life Prevents squeaking Prevents slip Increases belt tension force

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer. Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose. The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Request for a quote

KULLEN-KOTI GMBH

Germany

We can produce flat-belt brushes in any length requested, open ended or endless. They are mainly equipped with natural hairs or bristles, plant fibres or synthetic bristles. Depending on the fill material a brush surface from very soft to very hard can be obtained. As belt qualities we supply the multilayered types 5,8 mm or 7,0 mm (belt thickness) with a cover sheet and running surface made of chrome leather and an integrated polyamide insert. They are suitable for temperatures from -15°C to +80°C. When using endless closed belts, belt pre-tension is an important factor.For our types 4,8 mm to 9,5 mm we normally use a belt pre-tension of 1,5 to 2% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). Please ensure the diameters of the deflection pulleys (d) are correct in order to obtain an adequate looping of the belt. We advise you...

Request for a quote

FORBO SIEGLING GMBH

Germany

Textile Industry For decades Forbo Movement Systems has been accompanying the numerous developments in the manufacture of yarn and fabrics together with the textile machine manufacturers. The results are: Power transmission belts with thermoplastic tension members made of polyester and aramide as drive elements in yarn processing Cross-lapper belts with specially developed coatings New printing blankets for ideal printing results

Request for a quote

KULLEN-KOTI GMBH

Germany

For this brush type we use standardised vee-belt profiles, made of polyester elastomers and immune to moisture, oil and grease as well as resistant to numerous chemicals. Therefore an application is possible in a temperature range from -15°C to +80°C. They can be produced in all lenghts requested, open ended or endless closed belt. Mainly natural hairs and bristles, plant fibres and synthetic bristles (PA, PP, etc.) are used, so all kinds of brush surface - from very soft to very hard - can be obtained according to the material quality chosen. For the endless vee-belt brushes you normally have to use a belt pre-tension of 3% of the distance between the pulleys (a). In order to obtain this we recommend that an adjustment device (such as a slot) is used with an adjustment range of 5% of the distance between the pulleys (a). You can use standardised drive pulleys to drive the belt brushes.Please ensure the diameters of the deflection pulleys are correct in order to obtain an...

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The unique belt guide system allows the use of very small belt widths without the belt coming off the roller. The tensioning system ensures continual tension in the belt thus contributing to the safety of the guide system. Available in lever or rotary valve variants. Individual work through the rotatable head. Furthermore it has a protective cap for safe handling.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

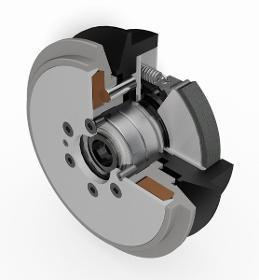

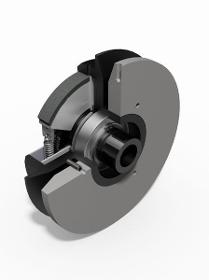

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

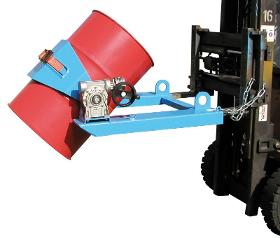

BAUER GMBH

Germany

-sturdy frame with fork sleeves -prism pick-up with tension belt and -double worm gear -can be secured to prevent slipping -load capacity 300 kg -range of rotation 360° -suitable for pick-up by a forklift truck, dumper or crane Types available -Type FLEX-HK tipping process by crank handle -Type FLEX-K tipping process by loop chain

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections. With its high flexibility, it can easily adapt to conditions on-site. The simple assembly operation is performed by means of tensioning belts. The system’s adaptation to the internal diameter is possible.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

IBK WIESEHAHN GMBH

Germany

Fabric compensators are highly flexible and usually made of multi-ply fabric, offering excellent temperature resistance and chemical resistance depending on the particular design. Mainly used in pipe and conduit systems to compensate for axial, lateral and angular movements. One major advantage of this type of compensator is the low restoring forces. Special fabric materials permit temperatures of up to 1,000°C. Additional insulation can be used to resist temperatures of up to 1,600°C . Applications: Chemical plants, refineries, metallurgical industry, ventilation systems, chimney construction, industrial furnace construction, power stations, boiler systems, waste incineration plants, acoustic decoupling. Materials: Kevlar, fibre glass, glass needle felt, stone mineral wool mats, ceramic fabric, ceramic fibre mats, silicate felt mats, silicate fabric, Teflon Connection types: Continuous screws and screwed counter flange, clamping bars, tensioning belts straps

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is of vital importance that the oriented mat be conveyed precisely from the forming line into the infeed head of the ContiRoll®. Otherwise a dependable production process and a symmetrical heating of both surfaces could not be guaranteed. We therefore use an intermediate belt, which is perfectly tuned to the exible infeed head of Siempelkamp’s ContiRoll® and which adjusts automatically to the respective recipe and process Parameters. Features Basic frame including belt drive Belt tracking unit Tensioning device Motorised slide table, swivelling and moving in production direction Pulley unit Advantages Preassembled unit, modular design integrated in the forming line Positioning of the slide table in the press infeed in dependence on the recipe Options Belt cleaning brush Seamless, endless belt

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Belt tensioners - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Conveyor belts (3)

- Clutches (2)

- Wood veneer - machinery and equipment (2)

- Beverage industry - machinery and equipment (1)

- Compensators (1)

- Grinding - machine tools (1)

- Handling of goods - motorized vehicles (1)

- Knives and scissors for household and professional use (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Shearing machine tools (1)

- Silicones (1)