- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial maintenance

Results for

Industrial maintenance - Import export

PLUGTITE

Belgium

For use in operations such as Electrostatic lines, die casting etc. where restistance to hightemperatures is required. Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Greater resistance to most oils and chemicals Can be used in situations up to 230°C (445°F) Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

PLUGTITE

Belgium

This plug is specifically produced for use in the food and beverage processing industry. The use of the plugs helps to ensure that sensitive working areas are kept free of contamination from oils and other fluids by preventing leakage when cleaning and servicing machinery and equipment Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Greater resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

PLUGTITE

Belgium

Helps prevent the leakage and contamination of various fluids, including hydraulics, and chemicals, during the service, maintenance, and storage of machinery and equipment. Small (2mm - 14mm) Medium (5mm - 24mm) Large (15mm - 45mm) Resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and release The compressed rubber ensures a tight fit

SDT ULTRASOUND SOLUTIONS

Belgium

CONMONSense delivers precise, repeatable data about the health of your assets and electrical systems also in the most challenging environment. Its resonant piezo element is optimized for ultrasound driven lubrication, mechanical fault detection, and monitoring the health of valves, steam, hydraulic systems and electrical defects. Ultrasound is a true measure of the FITness of your facility. Most assets produce FRICTION, IMPACTING, and TURBULENCE as defect indicators. CONMONSense hears these phenomena at their inception and delivers an analog signal response to your connected measurement system. With an output range from 4-20mA or from 0-10V, CONMONSense mounts permanently to any asset to provide continuous condition monitoring data. Avoid unplanned downtime and put the safety of your plant and colleagues first.

Request for a quote

POWER LUBE CONTROL SRL

Belgium

The patented Power Lube Sensor system can be installed on all lubrication points of the machine. It can be adapted to all kinds of oil and grease pumps installed upstream of the system (supplied via a central lubrication system or automatic lubricators or even gas system lubricator or manual pump, etc.). Description of the Power Lube Sensor ® Precise control and mastered alerts: The Power Lube Sensor Technology cleverly developed for data collection of up to 100 Power Lube Sensor units. Design and functional description: The Power Lube Sensor allows both to control the quantity / volume of lubricant as it passes through the electromechanical system and the remote transmission of alarms related to poor lubrication faults. It also controls the various alarms (battery level fault alarm, lubricant volume fault alarm, operating alarm, etc.) while adapting to all lubrication systems and industrial machine lubrication points system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POWER LUBE CONTROL SRL

Belgium

Power Lube IT Management is a powerful software for managing alarms and faults related to remote lubrication control never before designed and intended for maintenance professionals. It is an instrument for fault diagnosis and preventive maintenance technology developed specifically for the application of Improve your maintenance process. Increase productivity, reduce malfunctions, reduce maintenance costs ... How can Power Lube IT Management really help you? Automation of lubrication and maintenance controls Efficient planning and management Rationalization and efficiency of lubrication Real-time machine lubrication anomalies recording Reporting of malfunctions, alarms etc. Standardization of lubrication controls ...

Request for a quote

POWER LUBE CONTROL SRL

Belgium

The Power Lube Box Recorder (outdoor) provides for a solid out of the box experience for quick deployment in outdoor and harsh industrial environments. With its industrial grade components, it achieves a high standard of reliability. Power Lube Box Recorder is a gateway collecting and recording data sent remotely by Power Lube Sensors. Our Power Lube Box Recorder can record all data sent up to 100 Power Lube Sensor units. It allows you to connect LoRa wireless network to IP network via WiFi, Ethernet, 4G cellular. LoRa wireless allows users to send data and achieve extremely long ranges at low data rates. The Power Lube Box Recorder has pre-configured to use for different countries.

Request for a quote

LAMBIOTTE & CIE

Belgium

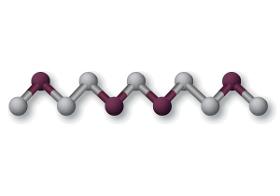

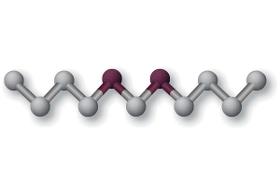

Molecular formulaC7H16O4 Molecular weight164.2 CAS number4431-83-8 EC number224-631-8 IUPAC name2,5,7,10- Tetraoxaundecane EC name2,5,7,10- Tetraoxaundecane

Request for a quote

LAMBIOTTE & CIE

Belgium

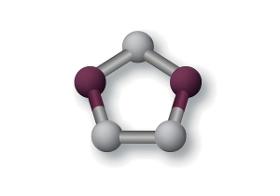

Molecular formulaC3H6O2 Molecular weight74.1 CAS number646-06-0 EC number211-463-5 IUPAC name1,3-Dioxolane EC name1,3-Dioxolane

Request for a quote

LAMBIOTTE & CIE

Belgium

Molecular formulaC9H20O2 Molecular weight160.3 CAS number2568-90-3 EC number219-909-0 IUPAC name1-(Butoxymethoxy)butane EC name1.1'-[Methylenebis(oxy)]dibutane

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Detect, Trend, and Analyze Ultrasound and Vibration. Detect, trend, and analyze asset health by viewing the ultrasound and vibration time signal and spectrum directly on the SDT340. A reliable asset delivers its engineered value when it is most needed. And while the responsibility for reliability belongs to everyone, it is the maintenance team who is called upon first, when things go wrong. For this reason, the SDT340 connects maintenance to reliability in ways we never imagined possible. Manage the results and organize your condition monitoring strategy by uploading them to the Ultranalysis® Suite 3 software (UAS3). Control any combination of assets and tasks thanks to its flexibility. SDT340 keeps inspectors connected to their assets. Live timewave and spectral views allow inspectors to perform in-the-field diagnosis and analysis, a job previously performed in the office.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Unlock a new era of industrial maintenance with the CRYSOUND Acoustic Imager. Our portable condition monitoring solution is designed to deliver unparalleled accuracy and adaptability in detecting compressed air leaks and partial discharges in the most challenging environments. The CRY2624 is certified with an explosion-proof level II 3G Ex ic IIC T5 Gc rating. It’s your trusted companion in chemical plants housing hazardous flammable gases and areas with strict explosion protection requirements. Our ultrasound camera features 128 state-of-the-art MEMS sensors, ensuring ultra-sensitive detection of compressed air leaks. It covers distances of up to 120 meters and displays the exact defect distance on the camera screen. The CRYSOUND Range caters to all your needs, offering solutions from basic (CRY2620) to superior (CRY2623), including the ATEX-certified CRY2624. User-friendly with just two parameters for most tests, it supports camera mode, video mode, and on-site data recording.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Detecting mechanical faults before they stop production Bearing and Machine Maintenance Industry runs on machinery. Bearings, pumps, electric motors, compressors, presses, gearboxes and much more. All of which can break unexpectedly, causing production to stop. When production stops your organization loses money. Few bearings make it to the end of their engineered lifecycle. This is due to poor workmanship, bad lubrication practices and neglect. Problems can even arise right after installation due poor installment of the machine. No two machines are the same. Across industry, machines operate under different loads, climates and conditions, making their maintenance requirements unpredictable. Many machines are still maintained on calendar based PM’s, while others are run-to-failure. Both strategies are wasteful.

Request for a quote

AUTOMATIC SYSTEMS

Belgium

The BL 53 barrier is the high security version of the BL 52 barrier. It is equipped with a boom and a reinforced arm, making any forcing attempt impossible, this passage can have a width of up to 8 meters. Robustness Operates even in the most difficult conditions Is suitable for industrial environments Barrier requires little maintenance Reinforced security Severely restricted passage Applications: Perimeter access (commercial, industrial, hospitals, sensitive sites ) Car parks

Request for a quoteResults for

Industrial maintenance - Import exportNumber of results

15 ProductsCompany type

Category

- Industrial maintenance (11)

- Cleaning and maintenance products, industrial (3)

- Rubber products (3)

- Chemicals - import-export (2)

- Ultrasonic measuring equipment (2)

- Chemistry, organic - raw materials and derivatives (1)

- Monitoring and control equipment (1)

- Scientific and technical monitoring (1)

- Sensors (1)