- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic mechanisms

Results for

Automatic mechanisms - Import export

MOBITEC

Belgium

Another new option for the Moods chair: a swivelling wooden base anchored to the centre of the seat, allowing your chair to turn through 360° with an automatic return mechanism. Very useful for taking a seat at the table without having to move your chair. Anything is possible in terms of upholstery (fabric, leather, leatherette). You can also choose the species and finish of the wooden legs. 3 good reasons to choose this chair Swivelling base Customisable Handy

Request for a quote

ROBINSON CO.

Turkey

◾ Fully PLC controlled. ◾ Precision weighing and long life with stainless steel load cells. ◾ 5/10kg.-10/25kg.and 25/50kg. weighing December. ◾ Automatic filling into bags with an open mouth. ◾ Lower and upper tolerance values that can be programmed separately. ◾ Automatic sack shaking mechanics. ◾ Separate weighing container feeding system according to the type of product to be bagged. ◾ Double coil feeding driven by separate motor. ◾ Single coil feeding driven by two-speed motor. ◾ Belt feed driven by two-speed motor. ◾ According to the product to be bagged and the desired tolerance, 13-22 tons/hour (50 kg. capacity Decoupled in bags) between. ◾ Special system panel from IP54 protection class ◾ Regulation bunker weighing unit and special vibration units in unloading bunkers. ◾ Easy calibration with keypad. ◾ Height adjustable sewing machine column.

Request for a quote

ROBINSON CO.

Turkey

◾ Fully PLC controlled. ◾ Precision weighing and long life with stainless steel load cells. ◾ 5/10kg.-10/25kg.and 25/50kg. weighing December. ◾ Automatic filling into bags with an open mouth. ◾ Lower and upper tolerance values that can be programmed separately. ◾ Automatic sack shaking mechanics. ◾ Separate weighing container feeding system according to the type of product to be bagged. ◾ Double coil feeding driven by separate motor. ◾ Single coil feeding driven by two-speed motor. ◾ Belt feed driven by two-speed motor. ◾ According to the product to be bagged and the desired tolerance, 13-22 tons/hour (50 kg. capacity Decoupled in bags) between. ◾ Special system panel from IP54 protection class ◾ Regulation bunker weighing unit and special vibration units in unloading bunkers. ◾ Easy calibration with keypad. ◾ Height adjustable sewing machine column.

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

GSW SCHWABE AG

Germany

Effortless 180° rotation via foot pedal and automatic mechanical locking Optional sensory position readout Crank Expansion via directionally stable joints, easily operable even under weight Highestquality Reel Arbor with maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability MHD Series PullOff Reel with manually adjustable brakes MHDM Series Payoff Reel with threephase motors for start / stop operation MHDR Series Payoff Reel with threephase motors and frequency inverter for continuous operation Optional Equipment MHDSeries Pneumatic hold down arms Electropneumatic brake systems Larger mandrel segments Motorized rotation Traveling feature w optional automatic centering Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc.

Request for a quote

GSW SCHWABE AG

Germany

Effortless 180° rotation via foot pedal and automatic mechanical locking Optional sensory position readout Strong plasmaburned back plate provides smooth and straight operation Removable and adjustable hub disks Fast and precise expansion via bevel gear with exceptionally wide ranges, allows clamping of all internationally common coil sizes LHD Series PullOff Reel with manually adjustable brakes LHDM Series Payoff Reel with threephase motors for start / stop operation LHDR Series Payoff Reel with threephase motors and frequency inverter for continuous operation Pneumatic hold down arms Electropneumatic brake systems Larger mandrel segments Conical mandrels Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc.

Request for a quote

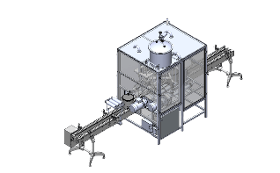

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 506D is fully automatic mechanical linear system It’s designed for filling liquid or pasty products in plastic bucket With five work stations: Adding buckets, filling, adding covers, pressing cover, Exiting

Request for a quote

LEMM MASCHINENBAU GMBH

Germany

Mechanical design Automatic load balancing Optional with external clamps for telescoping materials Capacity max. 150 / 250 kg The RWM-L reel turner allows for the problem-free changing of mandrels for various sleeve diameters.

Request for a quote

GSW SCHWABE AG

Germany

Effortless 180° rotation via foot pedal and automatic mechanical locking Optional sensory position readout Crank expansion via directionally stable joints, easily operable even under weight Highestquality arbor with maintenancefree bearing and minimal deflection Boxshaped stand with welded base plate for great stability LMHD Series PullOff Reel with manually adjustable brakes LMHDM Series Payoff Reel with threephase motors for start / stop operation LMHDR Series Payoff Reel with threephase motors and frequency inverter for continuous operation Pneumatic hold down arms Electropneumatic brake systems Larger mandrel segments Conical mandrels Traveling feature Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc.

Request for a quote

LALK GMBH &CO. KG

Germany

Professional mobile band saw with robust construction, automatic band tensioning mechanism and precisely guided folding cutting table for cutting large-sized aerated concrete blocks. The saw can be easily set up and operated by one person and is characterized by extreme cutting precision. The maximum cutting height is 650 mm.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SPIROL

Germany

SPIROL's Series LP500 Latch Pins for Plastics are designed with a barb located under the head with a barb length equal to the width of the outermost section of the assembly. The remaining length of the LP500 Latch Pin is smooth without any other retention features. This allows the LP500 Latch Pin for Plastic to easily align and freely install through all of the holes with a plastic assembly until the barb makes contact with the final hole to securely lock the pin in place. Once fully installed, the handle will pivot freely around the non-barbed end of the stationary pin. The head prevents the LP500 Latch Pin from being over-installed, and enables the pin to be mechanically oriented for automatic installation. Manufactured from lightweight, lead free aluminium, SPIROL's LP500 Latch Pins for Plastics are available in three standard diameters: 3mm, 4mm and 5mm.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

AccuBird® – Production • Developed and produced in Germany since 1992 by the inventor of the battery blind rivet setting tool Reliability • Electronic control • No mechanical switching components • Electronic temperature and overload protection • High reliability through low loss power transmission via a highly effi cient ball screw drive Freedom Cablefree tool for fl exible operation in installation jobs and industry production High performance • 10.000 N setting force • High pulling force for safe setting of blind rivets up to 5 mm diameter in all materials • High yield per battery charge • Large 20 mm stroke Versatility Blind rivets up to 5 mm Ø all materials. BULB-TITE® blind rivets 4 mm, 5,2 mm and 6,3 mm Ø alu and steel High speed • High speed of operation through automatic resetting of the jaw mechanism immediately after each setting process With Li-Ion energy • Choice of 2.0 Ah and 4.0 Ah Li-Ion batteries

Request for a quote

EMILIA FURNITURE

Poland

The BLUE collection is compact lounge furniture with a classic design. The seat structure is based on A-type wave springs covered with T-28 upholstery foam. The backrests are made of profiled upholstery foam. The collection includes: small BLUE corner sofa with a chaise lounge medium BLUE corner sofa with an ottoman large, panoramic corner sofa with an ottoman and a U-shaped chaise lounge The furniture is available in the configurations shown, with the option of choosing a left or right version. The corner sofas are equipped with a "DL" type sleeping function with a lowered backrest and a white bedding box located under the seat in the sleeping function. The seat is raised using an automatic lift mechanism.

Request for a quote

LABALABA COMPANY

Turkey

The product is manufactured using solid color elastane fabric and automatic metal mechanism. You can use the product on your braided hair, braided hair, and bun hair. It is recommended to use it by keeping away from perfume, cream, water and liquid chemicals. It requires delicate use. Product Dimension Information: 16 cm width, 28 cm length. Returns and exchanges are valid for unused and unopened products. Made in Turkey.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Move or dump more scrap with heavy-duty dumpers and industrial carts. PRAB’s line of industrial carts and automatic dumpers help move wet or dry metal chips, turnings and die scrap, safely and easily to and from scrap metal equipment. Customize the model and capacity cart you need with tow links, dumping frames, pouring baffles (contains cutting fluids), drain plugs, drain racks and casters designed to meet your floor conditions. Mechanical or automatic hydraulic dumpers help simplify the process of unloading carts. Improves housekeeping with efficient one-person operation Minimizes scrap handling costs Reduces production downtime

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CDA

France

The VST is an automatic module designed for the dispensing and pushing of headed caps. Crafted entirely from stainless steel, this linear machine is developed and produced by CDA. It efficiently dispenses T-shaped caps onto bottles and subsequently pushes them in. With a potential output of up to 1,800 corks per hour (dependent on cork type, etc.), the VST streamlines the capping process. Initially, the corks are placed in the cap lift hopper in a 'loose' manner. The lift then transfers the corks to an orientation bowl, ensuring they are correctly aligned. Subsequently, an automatic distribution mechanism on a ramp feeds the corks (oriented in the right direction) onto the bottle neck. Notably, the lift is a standard feature, enhancing autonomy and simplifying the operator's tasks. Specifically designed for T corks, commonly used in the food processing and distillery industries, the VST stands out for its adaptability and user-friendly operation and adjustment features, such as the

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Example defense project : FGMA / GM Family : Electric, hydraulics, mechanics, electronics, optic, automatism and embedded software studies and realization for a 3-D long-range Air Defense radar, offering detection from very high to very low altitudes AVE : This unit is mounted on military vehicle to detect the presence of nuclear, bacteriogolical and chimical on the ground. L’AVE is composed by the following elements : - Mechanical structure fixed on the vehicle - An arm actionned by an hydraulic actuator - A sensor box fixed at the end of the arm for analysis - A locking system to maintain the arm on folded position

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

WIND TENSIONERS Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer: Quality Means Lower Life-Cycle Costs: Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts Fully enclosed load cell eliminates debris in piston retraction mechanism Auto-Engaging Geared Nut Rotator Self-energizing, long life seals Enhanced Usability: Piston stroke limit indication High pressure swivel coupling (swivel is optional on WSS & WSL) 19,580 psi (1,350 bar maximum operating pressure) Automatic piston retraction mechanism Designed with Safety in Mind: Overstroke prevention for safe operation Anti-slip grip surface Tool lifting-strap as standard WSS & WSL FOUNDATION WIND TENSIONERS Suitable for ISO Metric threaded and all-thread bars Geared or Manual Nut Rotator Long & short stroke models Maximum operating pressure 19,580 psi (1350 bar) Uses standard system 'nut' for reaction Contact factor for op

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

WIND TENSIONERS Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer: Quality Means Lower Life-Cycle Costs: Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts Fully enclosed load cell eliminates debris in piston retraction mechanism Auto-Engaging Geared Nut Rotator Self-energizing, long life seals Enhanced Usability: Piston stroke limit indication High pressure swivel coupling (swivel is optional on WSS & WSL) 19,580 psi (1,350 bar maximum operating pressure) Automatic piston retraction mechanism Designed with Safety in Mind: Overstroke prevention for safe operation Anti-slip grip surface Tool lifting-strap as standard WSD COMPACT TOWER WIND TENSIONERS Robust Gearbox Drive Auto-Engaging Geared Nut Rotator Low height hydraulic load cell Fast application using 1/2" drive Cycle counter optional (Add “A” to end of part number) Maximum operating pressure 19,580 psi (1350 bar) Twin...

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

WIND TENSIONERS Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer: Quality Means Lower Life-Cycle Costs: Achieves 90% proof load requirement for ISO 898 Grade 10.9 bolts Fully enclosed load cell eliminates debris in piston retraction mechanism Auto-Engaging Geared Nut Rotator Self-energizing, long life seals Enhanced Usability: Piston stroke limit indication High pressure swivel coupling (swivel is optional on WSS & WSL) 19,580 psi (1,350 bar maximum operating pressure) Automatic piston retraction mechanism Designed with Safety in Mind: Overstroke prevention for safe operation Anti-slip grip surface Tool lifting-strap as standard WDD UP TOWER WIND TENSIONERS Robust Gearbox Drive Auto-Engaging Geared Nut Rotator Small diameter, high load 2-Stage hydraulic load cell Fast application using 1/2" drive Cycle counter optional (Add “A” to end of part number) Max Pressure: 19,580 psi (1,350...

Request for a quote

KEDY

Turkey

Automatic mechanical release hooks are a type of below-hook lifting equipment, which are used to secure and lift loads during material handling operations. They are typically used in industrial and construction settings, such as warehouses, factories, and construction sites, to lift and move heavy equipment, machinery, and other types of cargo. They are designed to automatically release the load when the load is lowered and grips onto the load when the equipment is lifted. They are also known as safety hooks, load release hooks, or automatic hooks. Contact us now to make your operations not only safer but also faster.

Request for a quote

KEDY

Turkey

Introducing the K4400 Mechanic Coil Lifting Tong - the cost-effective solution for handling large coils of material. With 20-ton capacity, max width & diameter of 2200mm, it's perfect for manufacturing & construction. No power required, easy to use & handle. Durable design, reliable performance & easy maneuverability. Save cost with KEDY's K4400, a cheaper alternative to electric coil tongs without compromising on performance. Equipped with advanced features that can be adjusted to lift and move coils with precision and ease. Our tong is designed to ensure safety, efficiency and productivity. The ergonomic design of the handle and lever makes it comfortable to use, reducing operator fatigue, and improving overall productivity. Trust KEDY to provide you with a high-quality, reliable, and cost-effective solution for your material handling needs. Order now and experience the difference.

Request for a quote

OMEGA AIR

Slovenia

AOK20 has been developed for fully automatic discharging of condensate or any other non-aggressive fluid from compressed air system. The unit can be installed as external drain on any application specified. Condensate accumulates in the aluminium reservoir and when the level is high enough condensate is discharged from the system without any air losses. Direct acting valve is operated by precise level controlled floater which assures reliable and efficient operation. Thanks to robust aluminium housing AOK20 is suitable for heavy duty applications. AOK20 is also equipped with separate manual drain for venting. AOK20 can be used in variety of applications. For applications not listed please contact us or your local distributor.

Request for a quote

OMEGA AIR

Slovenia

Automatic mechanical condensate drain AOK 13PA has been developed for fully automatic discharging of condensate or any other non-aggressive fluid from compressed air system. The unit can be installed as external drain on any application specified below. Condensate accumulates in reservoir and when the level is high enough condensate is being discharged from the system without any air losses. Direct acting valve is operated by precise level-controlled floater which assures reliable and efficient operation. For any other technical gas please contact us or your local dealer. Automatic mechanical condensate drain AOK 13PA can be used in variety of applications. For applications not listed please contact us or your local dealer.

Request for a quote

OMEGA AIR

Slovenia

AOK16B is designed for fully automatic discharging of condensate or any other non aggressive fluid from compressed air system. For any other technical gas please contact us or your local distributor. AOK16B is easy to install inside to the filter housing. AOK16B can be used in a variety of applications. For applications not listed please contact us or your local distributor.

Request for a quote

KEDY

Turkey

The K2950 Automatic Beam Tong from KEDY is the ultimate tool for lifting and moving heavy beams and other objects with ease and precision. Its innovative locking mechanism eliminates the need for operator intervention, ensuring a safe and efficient lifting operation. The tongs lift loads evenly, ensuring the safety of your materials. The polyamide pads protect your materials from damage while lifting. The handles provide a convenient way for operators to guide the tongs, making it easy to maneuver and position the load. Additionally, the K2950 Automatic Beam Tong is built to last, constructed with durable materials and designed to withstand the rigors of heavy-duty use. Whether you're working in construction, industrial, or manufacturing settings, this tong is the perfect solution for all your heavy-lifting needs. With its advanced features and ease of use, the K2950 Automatic Beam Tong from KEDY is the best choice for professionals who demand the highest quality and performance.

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment.As Per International Standard

Request for a quoteResults for

Automatic mechanisms - Import exportNumber of results

73 ProductsCountries

Company type

Category

- Buckets and grabs, crane (6)

- Lifting equipment (4)

- Plastics - machines and material for industry (4)

- Mechanical transmission systems and components (3)

- Metal straightening machines (3)

- Bottling and filling - machinery and equipment (2)

- Textile dyeing - machinery and equipment (2)

- Weighbridges (2)

- Automation - systems and equipment (1)

- Bakery - machinery and equipment (1)

- Bakery - machinery and equipment (1)

- Bakery ovens (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Containers, metal (1)

- Coupling, pneumatic (1)

- ELECTRIC EQUIPMENT (1)

- Finished Metal Products (1)

- Flour milling - machinery and equipment (1)

- Flour-milling (1)

- Food packaging (1)