- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- working process

Results for

Working process - Import export

JOBO BORSTELFABRIEK BV

Netherlands

Technical brushes are specific brushes that are used in the industry to optimize certain work processes. Dimensional tolerances, skews, static charge, special fiber hairs or minimum tensile forces often have to be taken into account.

Request for a quote

MALAIKA TEXTILE AGENCY IMPORT EXPORT

Turkey

Our collaboration network consists of professionals with diverse talents and skills. This diversity enables the emergence of creative ideas and allows us to utilize the best talents at every stage of our work processes.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Logistics software solutions to optimise your work process The software house of Lödige Industries LogIT GmbH, the software house of Lödige Industries, has 30 years of experience in data processing and host systems in the field of logistics. Based on standardized software modules, we develop solutions tailored to the specific projects of our customers. Experience, practical knowledge and competent handling are guaranteed by specialists in data and information processing. Storage management, material flow and transport technique, data base applications are implemented in state of the art logistics software. LogIT GmbH realizes and optimizes business processes within the logistic chain, from primary production to recycling. Our products include: Manual consignment solutions for distribution centers (MAN-Log) Truck dock management (TRUCK-Log) Air cargo systems (Cargo Professional)

Request for a quote

BORNEMANN GMBH

Germany

Roller die Roller die for the roller process of round work pieces with or without starting slope. These dies can be given flexible texts from individual insert milling or wire-cut excavations. The selection of materials depends on the relevant use. During production, we are guided by your drawings or data.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This inline thermocouple is especially invented for using under humid conditions. Compared with normal wire production this wire isolation is made in one work process, both conductors get moulded in Teflon at the same time. With this wire the measurement equipment is protected from capillary rising moisture through the wire. gas-, steam- and watertight Temperature range: -75°C to +250 °C, short-duration to + 300 °C Wire type: Teflon,0.38 mm, solid, Tmax: +300 °C

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

DRESSLER GROUP

Germany

The result of our work? Powders ready for processing. Fully packed in sacks, cartons, Big Bags and other containers prepared for dispatch in our (GMP) warehouses.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dry cleaning systems The dry alternative for cleaning Easy on the material & thorough Many years of experience with the working processes and requirements of our customers led us to develop an alternative cleaning system. The term alternative is appropriate, because in contrast to using conventional washing machines we have taken a completely different path. Whereas they work with wash emulsions everything remains dry on our cleaning system equipped with a linear brush unit – but it is just as thorough! Features & benefits • Clean coils/blanks economically without “washing agents” • Best cleaning performance • Rugged steel construction suitable for press shops • Low maintenance For all sheet metals and blanks Our dry cleaning system is suitable for material widths from 500-4500 mm. It cleans individual profiled sheets of metal, galvanised blanks, tailored blanks and much more. The system not only effectively removes interfering particles, but at the same time it also homogeniz

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

Resource-saving, sustainable and future-oriented. In addition to a well-working recycling process, a functioning circular economy also requires extensive possibilities for using the recycled material. The use of mechanically recycled post-consumer recycled material is not yet feasible in the food industry at the present time and is prohibited by law. Outside the food industry, however, there are already various areas of application. Your desired article geometry can be developed individually.

Request for a quote

EC PLAZA

South Korea

Seunggwang's challenge to consider safety and eco-friendliness for the future of autonomous vehicles continues. "Seunggwang's challenge for molds that consider safety and eco-friendliness continues." All employees cooperate with each other, and we have received a lot of favorable reviews and trust from customers through win-win management with our partners based on a proactive work attitude, good quality, compliance with delivery, and credit transactions. We hope to become your trustworthy partner as a company that focuses on developing high-quality molds by practicing ESG management, becoming smart by building a smart factory, building a quick work process, standardizing molds by CAD/CAM, and automating process work.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The smart solution: Fully-automatic defatting machine ASD 460 enables removal of fat layers from loins and cutlets in predefined strengths. Advantages Fully-automatic recognition of the fat strength using Weber camera technology, with programmable controlled movementalong longitudinal profile Continuous work process Sensor-controlled electronic spring for perfect pressure application Uniform fat layers Considerable minimisation of reworking (trimming) Back bacon instead of small trimming cuts Clearly improved product image for cooking after slicing Product-specific blade holders Combinable with pre-installed derinder Options: Special Weber transport rollers Product-specific blade holders Product-specific pressure devices for products withand without bones Fixed or adjustable guide plates for supply and output belts

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

An efficiently sharpened saw blade is essential for productive and safe work processes. Tyrolit offers an extensive range of grinding tools for various saw blades, including chain saws, circular saws, band saws, and gang saws. Our abrasives are precisely matched to different grinding machines and tooth pitches for optimal sharpening results, featuring vitrified-bonded grinding wheels and resin-bonded diamond and CBN wheels for special applications. Tyrolit’s decades of experience are evident in our tools' grit qualities and innovative bond systems, ensuring optimal cutting edge quality. Our grinding tools for automatic chain saw sharpening machines promise extended service life and perfect tooth base radius matching. We also offer resin-bonded diamond wheels for special applications and CBN tools for grinding HSS and high-alloyed steels.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

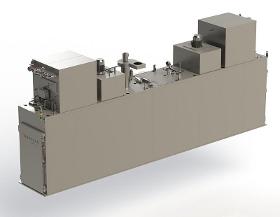

The ASCO Dry Ice Pelletizer P55i is one of the most powerful dry ice machines from ASCO's iSeries line. Having a production capacity of 550 kg/h (1'212 lb/h) it meets the demands for high dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P55i is driven by two powerful hydraulic units, which are running independently by the push of a button. This allows the production of identical or different pellet sizes in combination with the offered extruder plates at the same time.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

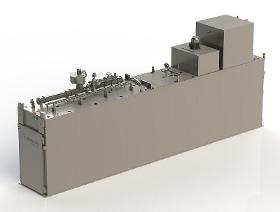

The ASCO Dry Ice Pelletizer P28i is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 280 kg/h (617 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P28i is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

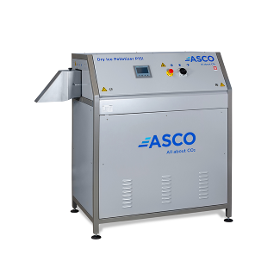

The ASCO Dry Ice Pelletizer P15(i) is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 150 kg/h (331 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As an optional model of ASCO's iSeries, it can be equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Whether for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P15(i) is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

HOVMAND A/S

Denmark

The battery-powered IMPACT 70 lifter is incredibly versatile. With its wide range of applications, it makes work processes more efficient, ergonomic and safe across many industries. It effortlessly moves, lifts and transports goods weighing up to 70 kg. Its "Commander" push-button control unit is easy to understand and can be operated from any position. For increased safety, the IMPACT 70 is additionally equipped with overload protection and safety clutch, and you can combine it with four different leg types, three mast heights and more than 15 different tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

SIKO GMBH

Germany

Incremental, miniature design, analog interface 1 V SS Profile LS100: Repeat accuracy max. ±1 μm Output circuit sin/cos 1 V SS Signal period 1000 μm (analog) Real-time signal processing Works with MB100/1 magnetic tape

Request for a quote

SIKO GMBH

Germany

Repeat accuracy max. ±1 μm. Output circuit sin/cos 1 VSS. Signal period 1000 μm (analog). Real-time signal processing. Works with MB100/1 magnetic tape.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Dynamic Spur Gearboxes MS-Graessner produces customer-specific spur gearboxes of a helical or straight-toothed design. The design of the toothing is carried out using KISSsoft and our own design and calculation programs. In addition to the provision of technical support and advice to our customers, we also take over the entire engineering process. By working closely together with our customers, we guarantee the development and production of the optimum drive solution in each case. Advantages: economical production simple mechanical movement and power transmission high level of efficiency high running smoothness high axial and radial loads low circumferential backlash broad range of applications long service life

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

The Planetary Gearbox for Power and Precision Full power with the highest levels of precision. The PlanetGear has the necessary power reserves available for the most challenging power transmission requirements. Advantages: compact design high level of efficiency high torsional rigidity low mass moment of inertia torque high overload capacity high dynamics large transmission ratios MS-Graessner offers innovative, customised gearbox solutions in a helical or straight-toothed design. The design of the toothing is carried out using KISSsoft and our own design and calculation programs. In addition to the provision of technical support and advice to our customers, we also take over the entire engineering process. By working closely together with our customers, we guarantee the development and production of the optimum drive solution in each case.

Request for a quote

HOVMAND A/S

Denmark

If there's something heavy to lift somewhere, the IMPACT 130 is certainly a reliable help. The IMPACT 130 is a powerful lifter that easily lifts loads of up to 130 kg for a variety of lifting tasks. Not for nothing is it the most popular lifter in our entire product range – and a great support in day-to-day work and manufacturing processes. For added protection and comfort, the IMPACT 130 is equipped with overload protection, a safety clutch and a soft start function for easy operation. For more specific requirements, the IMPACT 130 can be customised with a choice of five mast heights, different leg types and different wheels.

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Low effort and rapid processing • Especially for working with injection mortar cartridges • Ergonomic, non-slip handle • Sturdy, metal design • High quality alternative to the Profi model • Transmission ratio up to 1:18 Description & Area of Application • Guidance of the feed rod: The plastic in the core guarantees smooth gliding • Feed Plate: 2 thin metal layers with a plastic interlayer for problem-free dosing of the injection mortar • Riveted frame: Sufficient robustness to meet normal requirements • For the use of injection mortar with coaxial cartridges.

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

With our modern lathes and milling machines we can process thermoplastics according to the highest quality standards. We are using 3-axis as well as 5-axis milling machines. Example for our processing options: 3-axis machining up to a thickness of 80 mm and 1500 x 1000 mm format 5-axis machining up to a thickness of 700 mm and 2500 x 3000 mm format We manufacture according to provided drawings and CAD-data. Our programming stations are equipped with the latest CAD-CAM systems. Direct communication between job preparation and CNC work ensure a smooth process.

Request for a quote

TEPROSA GMBH

Germany

TEPROSA GmbH has specialized for many years in the manufacture of sophisticated, precisely fitting laminated cores of exceptionally high quality. In the field of electrical steel sheet, we manufacture individual laminations and sheets for stators and rotors, as well as entire sheet packages stator- or rotor packages) from various steel grades. We process grain oriented electrical steel for generators, transformers and other electrical machinery. Our most common method for packaging the individual laminations is baked enamel technology. Alternatives are welding or bolting of laminations. As a long-standing supplier to various OEMs, the quality of our work is particularly important to us. Therefore, we work according to uniform processes and thus ensure consistent quality and complete traceability of each individual production step.

Request for a quote

FÖHRENBACH GMBH

Germany

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

All stamping terminals and pins Hai Tong manufacture are customized and all rights will be reserved and non-disclosed to third party without written agreement from customer, this phosphorous bronze terminal is needed 6 million per year. Designed for application in automotive, we stamped this terminal from phosphorous bronze coil that was 0.5mm thick and apply tin plating as a finish and bulk packed for delivery. Our tolerances were maintained at ±0.02mm throughout the processes and we worked with the inventory to keep a schedule for just-in-time delivery, our production is 120000pcs daily with progressive die stamping, very cheap production cost to keep us competitive in the market and long term business relationship with customers.

Request for a quote

SACFORM/AGMLINE

Turkey

SACFORM/Agmline’s Specially Designed Double-Head Hydraulic Decoiler, By Means of Its Double Mandrel Design, Provides an Opportunity to Start Decoiling at The First Mandrel, While Placing the Second Coil. Thus, It Can Provide the Fastest Work with Eliminating the New Coil Loading Time Need Without Interrupting the Working Process.

Request for a quoteResults for

Working process - Import exportNumber of results

147 ProductsCountries

Company type

Category

- Knives, industrial (14)

- Finishing of surfaces - machinery (4)

- Internal transport systems (4)

- Laser - cutting and welding machines (4)

- Magnetic equipment (4)

- Medical Equipment (4)

- Cooling and lubrication pumps (3)

- Information systems - advice (3)

- Lifting equipment (3)

- Machine tools, metal machining - parts and accessories (3)

- Medical and surgical instruments (3)

- Milling - machine tools (3)

- Cooking and smoke-curing equipment for delicatessens (2)

- Food Processing (2)

- Gear pumps (2)

- Measurement and control instruments (2)

- Mechanical engineering - custom work (2)

- Mechanical transmission - components (2)

- Pharmaceutical industry - machinery and equipment (2)

- Welding robots (2)