- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- work stations

Results for

Work stations - Import export

LÖDIGE INDUSTRIES GMBH

Germany

For non-mechanized terminals, slave pallets are an essential tool for handling and transporting ULDs. The pallets are equipped with four rows of 16 non-powered rollers. There is a non-slip treadplate between the rollers that allows the pallet to be walked on. Slave pallets can be transported using powered conveyor systems or the Lödige Mini and Lödige Robby, as well as using our slave pallet mover. Flexible setup of work stations Flexible storage options Flexible transportation option IATA-compliant handling of ULDs Stackable to save space.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Quality at every level Safe transport and short throughput times — Lödige‘s material handling solutions easily accommodate all the demands made on them whether within the paint shop or in provision and intermediate storage after the painting process. Your advantages using Lödige solutions in the paint shop: Materials handling in multiple dimensions Connection to intermediate store Connection to body shell store Work stations Internal and external materials handling systems Materials handling systems and control technology from one source

Request for a quote

KW HYDRAULIK GMBH

Germany

Bus Bar Working Stations for Bus Bars and Flat Material

Request for a quote

KW HYDRAULIK GMBH

Germany

Bus Bar Working Stations for Bus Bars and Flat Material Punching Tools for Bus Bars and Flat Material Cutting Tools for Bus Bars and Flat Material Bending Tools for Bus Bars and Flat Material Brochure Tools for Control and Switchgear Cabinets Tools for Laminated and Flexible Bars and Earthground Sheet Metall Hole Puncher DIN Mounting Rail Cutting Devices Wiring Duct Cutting Tool Punching Tools for Sheat Metall

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

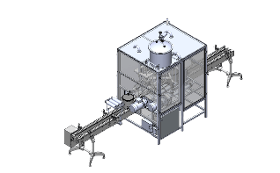

Challenger 506D is fully automatic mechanical linear system It’s designed for filling liquid or pasty products in plastic bucket With five work stations: Adding buckets, filling, adding covers, pressing cover, Exiting

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

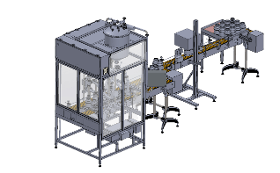

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

WEBER ULTRASONICS AG

Germany

This space-saving Plug & Play system is preconfigured and ready to use. The Saphir Manual Station offers a multitude of uses and configuration possibilities. It can be operated as an individual work station or in semi-automatic mode and is equipped with quality components of Weber Ultrasonics.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Wireless Error Proofing System. The Global 400 performs as a station dedicated process controller that organizes, directs workers, tools, and tasks. It also brings a powerful networking capability not previously available in the Global 8 and the Global 100 series. Mixed Model Manufacturing Mandates Flexibility Sturtevant Richmont specializes in solving the most complex assembly challenges. The Global 400 is designed to organize work stations where highly customized products are assembled. It can work with 16 primary torque tools, 8 holding tools, and an additional 8 I/O tools. It has the capacity for 100 sets of parameters that can be grouped allowing 4 operators to work as a team. These parameters or groups can be formed into jobs containing a fixed build sequence of put to 35 steps. Mixed Model Manufacturing Mandates Communication The Global 400 communicates with the operators, the tools, and your network in multiple ways. [...]

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Space-saving The AGO-Wipe collecting tray is characterized by functional design, superb styling and an attractive range of colours. The space-saving waste collector is guaranteed to bring organization and order to any kitchen environment. Universal usability for a wide variety of strip handles and finger grips on drawers plus the compact shape and size give rise to the unmistakable and practical AGOFORM design. Integration The hygienic waste collector made of high-resistant plastic is easily integrated into the kitchen and takes up very little space. It fits on all standard-sized drawers. The collecting capacity of 2.6 l makes it easy to keep kitchen work stations clean and tidy.

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Space-saving The AGO-Wipe collecting tray is characterized by functional design, superb styling and an attractive range of colours. The space-saving waste collector is guaranteed to bring organization and order to any kitchen environment. Universal usability for a wide variety of strip handles and finger grips on drawers plus the compact shape and size give rise to the unmistakable and practical AGOFORM design. Integration The hygienic waste collector made of high-resistant plastic is easily integrated into the kitchen and takes up very little space. It fits on all standard-sized drawers. The collecting capacity of 2.6 l makes it easy to keep kitchen work stations clean and tidy.

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

Space-saving The AGO-Wipe collecting tray is characterized by functional design, superb styling and an attractive range of colours. The space-saving waste collector is guaranteed to bring organization and order to any kitchen environment. Universal usability for a wide variety of strip handles and finger grips on drawers plus the compact shape and size give rise to the unmistakable and practical AGOFORM design. Integration The hygienic waste collector made of high-resistant plastic is easily integrated into the kitchen and takes up very little space. It fits on all standard-sized drawers. The collecting capacity of 2.6 l makes it easy to keep kitchen work stations clean and tidy.

Request for a quote

FERPLAST SNC

Italy

PORTABLE INKJET MARKER MOD. FPA2-SMART MOB - MAXIMUM PRINTING HEIGHT 12.7 mm New portable inkjet marker, suitable for marking on porous, semi-porous (boxes, cardboard boxes) in different work stations. Allows to print alphanumeric texts, logos, date/time, codes, counter, lot and 1D & 2D barcode, distributed on 4 lines with a total height of 12.7 mm. The marking speed is set directly on the marker keypad and you can always write accurately and without deformation of the characters. The cartridges are independent and directly in contact with the print head. The marker is equipped with an automatic nozzle cleaning system so in case of very long machine stops, there is no danger of blocking, but simply replace the exhausted cartridges without further maintenance. The message to be printed can be set by PC in any Word font format. To use it, simply save it on the SD card included in the machine.

Request for a quote

BÜRKLE GMBH

Germany

Mini eyewash station ideal for the lab, filling stations or all work places where aggressive substances are used. Eyes Fresh can be attached to any standard cold water tap. For normal use of the tap, just press the button and the function changes back from the eye wash (returns automatically to eyewash-function when the tap is closed). Can be fitted onto taps with M22x1, 1/2" or 3/8" outer thread. With sufficient water pressure provided, performance according to DIN EN 15154-2.

Request for a quote

LITAN - ESTANTES METÁLICAS, LDA

Portugal

These shelves make the most of the useful height of a given location, doubling or tripling its surface and transforming it in a storage area. The installation of a platform is the best solution to make the most of the available space. There´s the option of using all the available surface or using only the highest areas of the facility. USE The installation of a platform allows allocating that surface to different applications: work stations, components assembly, requests preparation area, storage, etc., even office space. The installation is formed by a raised floor. In the ground floor there could be shelves to store small and medium size merchandise and with largest number of Picking operations. The upper floor can be used to store the bigger volume and less consumed items. The platform can also be united to a Picking warehouse with footbridges as a reception and order preparation area and a lift platform to transport the merchandise up and down from the different levels.

Request for a quote

MARTIN GROUP SRL

Italy

preparation and loadins systemwith non running belt cold belt for a better comfort of the work station start impulse through knee bandage so that the operator's hands are always free electronic self-adjustment off speed according to the fusing machine belt matheable other also for an easy working of big pieces selector for utilization of always non running belts or of some non running and some running belts ALSO ADJUSTABLE TO ALREDY AXISTING FUSING MACHINES BOTH MARTIN AND OF OTHER BRANDS Avaible in the following patterns: 1 SINGLE BELT - 1 DOUBLE BELT 2 NASTRI DOPPI - 3 DOUBLES BELTS other combinations on request

Request for a quote

GEDA GMBH

Germany

The permanently installed GEDA 1200 ZP P transport platform is the strong and versatile partner for heavy loads and efficient working. People and materials are transported quickly, but – most importantly – safely. The wide range of industrial applications include asphalt mixing systems, power stations, cement works, chemical plants as well as the warehousing and logistics sector. With the flexible system, the GEDA 1200 ZP P transport platform can be adapted to individual customer requirements and on-site conditions. In addition to the three different speed variants, there is also an extensive range of platform versions. The highlight: Despite the high load capacity of 1,500 kg, the GEDA 1200 ZP P transport platform is guided on only one mast, thanks to the low anchoring forces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERGOSWISS AG

Switzerland

Elegant and stable The system TU is ideal for assembly work stations with high load and stability demands. The crossbars are fixed to the welded mounting plate. In combination with crossbars of different lengths, the system enables the height adjustment of table tops of various sizes. The system is driven by a hand crank or an electric drive unit. Accessories

Request for a quote

ERGOSWISS AG

Switzerland

Elegant and flexible The system TQ is perfect for assembly work stations made of aluminium profiles and for undermounting in multi-line conveyor systems. The T-slots (8 mm wide) allow the addition of crossbars, shelves, attachments and mountings along the entire length of the leg. The TQ leg consists of an extruded aluminium profile with a plain anodised finish. The stainless-steel tube is mounted on slide guides. The lifting movement is provided by hydraulic cylinders. Accessories

Request for a quote

ERGOSWISS AG

Switzerland

High loads with small dimension The housing of the linear units SLA and SLG are made out of colorless anodized aluminium profiles with dimensions 35x35 mm (SLA) or 45x45 mm (SLG). Up to 4 linear units can be connected to one control box and are operated synchronous with a hand switch. The systems SLA and SLG are used in applications which need ergonomic height adjustable work surfaces. Especially existing work stations can be retrofitted with linear units. The dimensions 35x35 mm and 45x45 mm fit perfectly in steel profiles 40x40 mm or 50x50 mm, which are often used as carriers and legs for work stations. Compared to to the linear unit SLA, the SLG can withstand higher bending moments and is more stable. We recommend the SLA and SLG linear unit for industry, furniture and catering. The following accessories are available: mounting plates adjustable rubber foots aluminum feet castors tube fitting (only for SLA)

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

ERGOSWISS AG

Switzerland

High loads with small dimension The housing of the linear units SLA and SLG are made out of colorless anodized aluminium profiles with dimensions 35x35 mm (SLA) or 45x45 mm (SLG). Up to 4 linear units can be connected to one control box and are operated synchronous with a hand switch. The systems SLA and SLG are used in applications which need ergonomic height adjustable work surfaces. Especially existing work stations can be retrofitted with linear units. The dimensions 35x35 mm and 45x45 mm fit perfectly in steel profiles 40x40 mm or 50x50 mm, which are often used as carriers and legs for work stations. Compared to to the linear unit SLA, the SLG can withstand higher bending moments and is more stable. We recommend the SLA and SLG linear unit for industry, furniture and catering. The following accessories are available: mounting plates adjustable rubber foots aluminum feet castors tube fitting (only for SLA)

Request for a quote

LVD

Belgium

MOVit Tower Automation System (TAS) is a single or double tower storage system for integration with one or two laser cutting machines in 3015, 4020 or 6020 formats. Available in 16 possible configurations, TAS offers a continuously-ready material supply to keep machine output at its peak. An optional direct unload station allows processed work pieces to be offloaded for sorting or secondary processing. KEY FEATURES Efficient storage and retrieval of raw materials Continuous material flow for uninterrupted and lights-out production Optimized use of floor space Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) tower station 16 possible system configurations MODELS Available for Phoenix and Electra series (TAS 3015, TAS 4020 and TAS 6020) Specifications 3-ton capacity per pallet (5-ton for 6020) Up to 63 pallets, depending on system configuration Stack height of 90 mm

Request for a quote

NANOSYSTEC GMBH

Germany

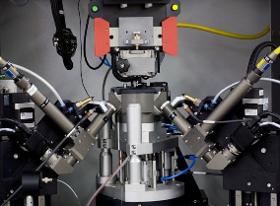

The NanoWeld stations provide the ideal platform for the development and production of opto-electronic components, like singleand multi-channel transmitters and receivers. The station works with exchangeable trays and grippers accepting all device housing types and lenses, optical fibers or receptacles to be aligned and attached. Cycle times for the rapid mass production of TOSA type assemblies reach less than 25 seconds while it takes several minutes for complex devices.All components and subassemblies to build the NanoWeld station are of highest quality and performance. Even customized systems start from a common platform which minimizes development time and cost. By using device-specific trays and grippers, the time to change between different batch processes or device types is reduced to the minimum. Loading and unloading of these trays is performed on a separate loading station outside of the automated NanoWeld. The automated alignment starts from a known reference position.

Request for a quote

RUHLAMAT GMBH

Germany

Are you looking for a flexible means of increasing your production and would thereby like to find out about a proven investment? Manual workstations from ruhlamat based on the Chaku Chaku principle provide the best solution to support you here. The worker assumes only the transport of workpieces from station to station for solutions based on the Chaku Chaku principle. The stations themselves work fully, or at least semi-automatically, where cycle time differences between the stations are absorbed by buffers. Manual workstations can be an ideal solution particularly in the case of uncertain part quantity forecasts since it can be the most flexible method of responding to fluctuations in part numbers thanks to different deployment of personnel (single or multi-station operation). The manual workstations from ruhlamat can be planned jointly with the customer taking into account the prospective issue of quantities. As a result, subsequent expansion with linear transfer systems or...

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Packing and working table electrically height-adjustable Overhead unit light at the packing station With electric lifting axle for easy change of the roll at the overhead unit Mouse and keyboard tray Small rear wall board cardboard magazine Swiveling TFT arm signal lamp Holder for waste bin and tape dispenser AirWave1 Air Cushion Machine

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Packing and working table electrically height-adjustable Overhead unit light at the packing station With electric lifting axle for easy change of the roll at the overhead unit Mouse and keyboard tray Small rear wall board cardboard magazine Swiveling TFT arm signal lamp Holder for waste bin and tape dispenser AirWave2 Air Cushion Machine

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The solid machine design of the h-frame press with section steel frame structure is the basis for integration of multi-head tools. Equipment with up to 16 ultrasonic generators allows for cycle time-optimized process sequences in one processing station. The weld tools are moved far up by means of a pneumatically operated H-frame so that large-volume plastic components can be comfortably loaded into the work station. Additional solutions available for quick and safe tool change.

Request for a quoteResults for

Work stations - Import exportNumber of results

62 ProductsCountries

Category

- Packing and packaging - machinery and equipment (10)

- Shoes - industrial machinery (6)

- Automation - systems and equipment (3)

- Laser - cutting and welding machines (2)

- Sanitation (2)

- Advertising studios (1)

- Clothing industry - machinery and equipment (1)

- Extrusion of rubber and plastic (1)

- Foundry machines - centrifugal (1)

- Hoists and elevators, construction (1)

- Hospital furnishings (1)

- Hydrometers (1)

- Import-export - electrical and electronic equipment (1)

- Induction heating systems (1)

- Injection moulding of rubber and plastic (1)

- Ink jet printing (1)

- Laboratory equipment and instruments (1)

- Lighting, street, industrial and commercial (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Mechanical engineering - custom work (1)