- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire welding

Results for

Wire welding - Import export

PEMAT S.C.

Poland

WELDING WIRE with weaving SG2 Copper-clad welding wire for the MAG method for welding low-alloy and fine-grained steels. Application in steel structures and building reinforcements. Diameter: 0.8 mm Spool: D200 Weight: 5.0 kg AWS: A5.18-ER70S-6 EN ISO 14341-A G42 4 M21 3Si1

Request for a quote

PEMAT S.C.

Poland

WELDING WIRE SG2 1KG 0.8MM VOGELMANN SG2 copper-plated welding wire intended for welding low-carbon and low-alloy steels in carbon dioxide (CO²) shielding or a mixture of argon and dioxide (Ar + CO²) gases. TECHNICAL DATA : Wire diameter: 0.8mm Roll weight: 1 kg Quality standard: SG2 / ER70S-6 Roll Type: D100 Total diameter of the spool: 100 mm Tensile strength: 540 MPa

Request for a quote

PEMAT S.C.

Poland

Copper solid wire with the addition of manganese and silicon, intended for MIG / MAG (GMAW) welding of non-alloy steels, such as general structural steels, steels for pressure vessels and marine steels, as well as for welding fine-grained carbon-manganese steels for the same purpose , with a minimum yield strength of less than 420 MPa. When welding with OK Autrod 12.51 filler wire, Ar / 20CO2 or pure CO2 can be used as the shielding gas. OK Autrod 12.51 wire in ESAB's unique Octagonal Marathon Pac packaging is perfect for mechanized welding processes. TECHNICAL PARAMETERS Wire diameter: 0.8 mm Roll weight: 5 kg Spool diameter: 200mm Shielding gas used: CO2, Ar / CO2 mixture

Request for a quote

PEMAT S.C.

Poland

One piece spool adapter for welding wire D300 Vogelmann Brand new spool adapter for MIG wires on a metal 300mm spool. The adapter enables efficient installation of the spool in the welding device.

Request for a quote

PEMAT S.C.

Poland

WELDING WIRE SG2 5KG 0,8MM VOGELMANN Mild steel welding wire designed for welding low-carbon and low-alloy steels in the carbon dioxide (CO²) shield or a mixture of gases of argon and dioxide (Ar + CO²). TECHNICAL DATA: Diameter: 0,8 mm Weight: 5 kg Quality standard: SG2 / ER70S-6 Roll type: D200 Total diameter of the spool: 200 mm Tensile Strenght Rm (Mpa): 540 MPa

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

aluminum welding wire MIG/MAG (GMAW) Welding | ED701763 General purpose filler alloy for 5XXX and 6XXX series alloys The most widely used soldering alloy High strength filler metal

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Copper-plated wire for structural welding of carbon steel and C-Mn with mixed shielding gases based on CO2 and Ar. Used for general applications. Good power and soldering ability Standard production process and standard certifications

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Copper clad solid wire used in general purpose, single or multipass soldering for use with CO2 shielding gas or Air/CO2 mixture. MIG/MAG welding (GMAW)

Request for a quote

SINOP SMP

Czech Rep.

For high volume production, but also for smaller batches MIG/MAG welding TIG (WIG) welding with wire feeding MIG soldering with an additional material CuSi Fixture design and development in house

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our weld wire sheathing material is used in both flux cored wire and metal cored welding wire processes. The wire sheathing is formed into a tubular product by our customers and the center of the tube contains the ‘fill’ (flux, metal powders, etc) to bring the wire to the desired chemistry. The finished wire is used across a wide breadth of industries in processes such as: Submerged Arc Welding (SMAW) Gas Metal Arc Welding (GMAW) Wire Arc Thermal Spray Flux cored welding wire producers use our metal sheathing materials to prepare finished wire for thermal spray and in surfacing applications, in high temperature and corrosive environments. Cobalt Our Ductile Cobalt Alloys are used to produce wire to hardface applications in the construction, mining, and oil and gas industry. Our proprietary process allows us to offer high Cobalt containing products (91% Cobalt or more) while maintaining a highly ductile strip for wire forming.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Wire rod is an excellent consumable for the production and manufacture of knitting, spring, welding wire; electrodes for electric arc welding; hardware products; masonry and other mesh; ropes (cable) ; formwork manufacturing; concrete structures; metal structures . Wire rod can be either hot or cold rolled carbon steel. It is drawn on special drawing machines by drawing to a thickness of 5 to 15 mm onto special winding spools. The weight of one coil of wire rod is on average from 160 kg, depending on the initial diameter, order or consignment of goods. A circle of small diameters is made from rolled hot rolled wire by cutting; the product can also be supplied in bars. Quality The quality of the wire rod corresponds to GOST 30136 and is confirmed by certificates. Steel grade 3PS, 1PS, 2PS, 1KP, 2KP, 3KP, 1SP, 2SP, 3SP. Rolled wire is produced with the following strength classes B standard; B increased. You can contact us by mail - marketing@stalevar.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

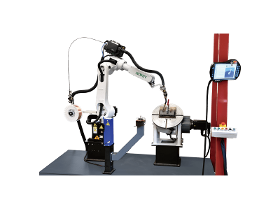

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WDM DEUTENBERG GMBH

Germany

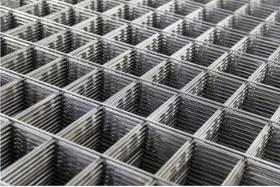

The central product of WDM Deutenberg are spot-welded wire meshes according to individual specifications. There are four different wire materials used to produce our wire meshes and wire mesh elements: bare wire, galvanized wire, aluminium galvanized wire and stainless steel wire. Our spot-welded wire meshes have different sizes from 300 x 250 mm to 8,000 x 2,400 mm depending on mesh width and wire diameters. Mesh widths between 20 mm x 20 mm minimum and 150 mm x 150 mm maximum and diameters from 2.0 mm to 18.0 mm are possible. The scope of application of our spot-welded wire meshes is very diverse. They are used in industries such as landscaping, agriculture, engineering, shopfitting, metalworking, food industry, electrical industry, construction industry or retail. Please call us for further questions under +49 (0) 38789 / 879-0 an or write us an e-mail to info@wdm-wolfshagen.de.

Request for a quote

MÃO DE FOGO

Portugal

For Artists who want to carry out their own finishing on the sculptures after casting, we offer our facilities for finishing. A workstation will be available with compressed air tools, electrical tools, a TIG and MIG welding machine and a cleaning machine. by sandblasting. Consumables such as cutting discs, drills, welding wire and rods, etc. can be purchased at our foundry or brought by yourself.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 200 °C Ni Temperature Sensor Series offers an excellent long-term stability and simple linearization within a temperature range of -60 °C to +200 °C. The sensors are offered with Ag-wire (Ø 0.25 mm), with Au-coated Ni-wire or flat wire and with Cu/Ag-wire with PTFE-insulation in various standard lengths. The directly welded wires offer outstanding robustness and are optimal for soldering, welding and crimping. The nickel temperature sensors are vibration and temperature shock resistant with simple interchangeability and small dimensions. Furthermore, the 200 °C Ni Temperature Sensor Series can be customized to fit application-specific requirements. The IST AG nickel temperature sensors up to 200 °C are also available with: — Wire lengths fitted to application-specific requirements — Insulated wires — Flat wires — Metallized backside

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 400 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +400 °C. The sensors are vibration and temperature shock resistant and offer excellent solderability. The standard 400 °C Pt Temperature Sensor Series is supplied with Ag-wires. Due to the wire material characteristics, the long directly welded Ag-wire shows very little impact on the sensor accuracy. Furthermore, the 400 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. PTFE-insulation tubes. The IST AG Pt temperature sensors up to 400 °C are also available with: — Paired and grouped sensors — 1/5 IEC and 1/10 IEC accuracy — 2-, 3- and 4-wire configuration — Grain-stabilized Ag-wire

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 150 °C Pt Temperature Sensor Series offers excellent long-term stability and fast response time with low self-heating within a temperature range of -50 °C to +150 °C. The sensors are developed with an insulated enameled Cu-wire, which enables easy integrating into applications. The insulation is additionally removed at the end of the wire to enable easy welding or soldering. Due to the small diameter of the enameled Cu-wire (Ø 0.2 mm), the temperature sensor is offered with extremely small dimensions (see "characteristics" for more information about small dimensions) and with long, directly welded wires. Furthermore, the 150 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths. The IST AG Pt temperature sensors up to 150 °C are also available with: — Metallized backside — Long insulated wires (enameled) — 2-, 3- and 4-wire configuration

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 150 °C Pt Temperature Sensor Series offers excellent long-term stability and fast response time with low self-heating within a temperature range of -50 °C to +150 °C. The sensors are developed with an insulated enameled Cu-wire, which enables easy integrating into applications. The insulation is additionally removed at the end of the wire to enable easy welding or soldering. Due to the small diameter of the enameled Cu-wire (Ø 0.2 mm), the temperature sensor is offered with extremely small dimensions (see "characteristics" for more information about small dimensions) and with long, directly welded wires. Furthermore, the 150 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths. The IST AG Pt temperature sensors up to 150 °C are also available with: — Metallized backside — Long insulated wires (enameled) — 2-, 3- and 4-wire configuration

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 150 °C Pt Temperature Sensor Series offers excellent long-term stability and fast response time with low self-heating within a temperature range of -50 °C to +150 °C. The sensors are developed with an insulated enameled Cu-wire, which enables easy integrating into applications. The insulation is additionally removed at the end of the wire to enable easy welding or soldering. Due to the small diameter of the enameled Cu-wire (Ø 0.2 mm), the temperature sensor is offered with extremely small dimensions (see "characteristics" for more information about small dimensions) and with long, directly welded wires. Furthermore, the 150 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths. The IST AG Pt temperature sensors up to 150 °C are also available with: — Metallized backside — Long insulated wires (enameled) — 2-, 3- and 4-wire configuration

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 200 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +200 °C. The sensors are offered in various standard lengths with Cu/Ag- single or stranded wire with PTFE -insulation. The directly welded wires offer an outstanding robustness and are optimal for connector assemblies or for soldering, welding and crimping. Additionally, the 200 °C Pt temperature sensors are also available with Ag-wire (Ø 0.25 mm) and metallized backside. Furthermore, the 200 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. different insulation materials or lead wire diameters. The IST AG Pt temperature sensors up to 200 °C are also available with: — Metallized backside — Wire lengths fitted to application-specific wire lengths — Ends stripped to optimize welding processes — 2-, 3- and 4-wire configuration

Request for a quote

EUROWIRE LDA

Portugal

Stainless Steel Welded Wire Mesh Fencing

Request for a quote

EUROWIRE LDA

Portugal

Safe and solid, it offers rigidity and security to the different areas to be fenced.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Sealing bar type BS for sealing and closing bags: - From PE - From PP - From soft PVC - From polyamide PVC Features: Equipped with a potentiometer for setting the welding time and a high-quality welding rod. The BS...C models are equipped with a manual cutting blade. The BS...CF models are equipped with a round welding wire cutter.

Request for a quoteResults for

Wire welding - Import exportNumber of results

150 ProductsCountries

Company type

Category

- Wires and cables, steel (24)

- Wire mesh, welded (17)

- Steels and metals - welding and brazing (10)

- Gases, compressed and liquefied (7)

- Copper and copper alloys (6)

- Sensors (6)

- Aluminium and aluminium alloys (5)

- Ceramics (4)

- Fences (4)

- Wire mesh (4)

- Containers, metal (3)

- Fencing - equipment and supplies (3)

- Harvesting machinery and equipment (3)

- Laser - cutting and welding machines (3)

- Welding work - steels and metal (3)

- Chains, wire - with non-welded links (2)

- Gas, compressed (2)

- Gratings, metal (2)

- Sheet metal and strips, tinplate (2)

- Welding, electric - equipment and supplies (2)