- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire welding

Results for

Wire welding - Import export

WDM DEUTENBERG GMBH

Germany

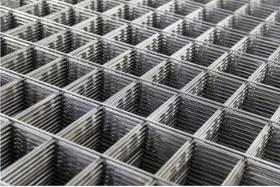

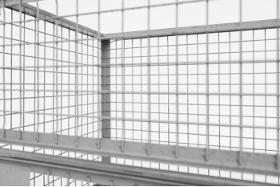

The central product of WDM Deutenberg are spot-welded wire meshes according to individual specifications. There are four different wire materials used to produce our wire meshes and wire mesh elements: bare wire, galvanized wire, aluminium galvanized wire and stainless steel wire. Our spot-welded wire meshes have different sizes from 300 x 250 mm to 8,000 x 2,400 mm depending on mesh width and wire diameters. Mesh widths between 20 mm x 20 mm minimum and 150 mm x 150 mm maximum and diameters from 2.0 mm to 18.0 mm are possible. The scope of application of our spot-welded wire meshes is very diverse. They are used in industries such as landscaping, agriculture, engineering, shopfitting, metalworking, food industry, electrical industry, construction industry or retail. Please call us for further questions under +49 (0) 38789 / 879-0 an or write us an e-mail to info@wdm-wolfshagen.de.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Sealing bar type BS for sealing and closing bags: - From PE - From PP - From soft PVC - From polyamide PVC Features: Equipped with a potentiometer for setting the welding time and a high-quality welding rod. The BS...C models are equipped with a manual cutting blade. The BS...CF models are equipped with a round welding wire cutter.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

A new generation of bright welding wires With the development of WDI PLATINARC, we have succeeded in combining the good properties of copper-plated and non-copper-plated welding wires. The Platinarc welding consumables are characterised by therefore by: Low contact tip wear Best wire feeding properties Minimal silicate precipitation in the weld sea Low splash formation Low copper content in welding fumes Stable electric arc

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

WDI's welding wire production at the Hamm/Westf. and Rothenburg/Saale /Wettin.Löbejün) sites can look back on a history of almost 50 years. Unalloyed and low-alloyed inert gas and submerged arc wire electrodes have been manufactured at WDI's main plant in Hamm/Westphalia since 1975 and at WDI in Rothenburg in central Germany since 1993. Production at both sites was gradually expanded and today, with a production capacity of up to 60,000 tonnes p.a., is one of the largest production facilities for welding wires in Europe. There is hardly a steel processing company in Germany or Europe that is not familiar with the wire electrodes from Hamm and Rothenburg. Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

ORBITEC GMBH

Germany

With tube-to-tubesheet weld heads, it is possible to achieve consistently high-quality, reproducible welding of tubes to tubesheets, with or without additional wire. The tubes to be welded can be flush with the tubesheet, offset, protruding or behind the tubesheet. The RBK 38 S and the RBK 60 S are our two new tube-to-tubesheet weld heads. The RBK 38 S is a small, handy water-cooled head for welding tubes to tubesheets up to an ID of 36.7 mm, without additional wire. Package includes: — Weld head — Water-cooled hose package, 6 m — Pull bar B — Gas hood ID 35 mm — 0° electrode holder — Transport case Optional: — Div. electrode holders for RBK 38 S — Div. gas hoods for RBK 38 S — Div. spring sleeves and pull bar sets for RBK 38 S

Request for a quote

WDM DEUTENBERG GMBH

Germany

Spot-welded wire meshes from WDM Deutenberg offer the required stability, sustainability and safety regarding production, further processing and usage of your transport equipment.

Request for a quote

KÖSTER & CO. GMBH

Germany

Ideal for shear studs and threaded studs High repeatability Hydraulic plunge damper Standard support with 2 legs Body Polyamid Compensation for stud length variations up to 8mm Control cable plug (4 wire) Stud welding with shielding gas: optional

Request for a quote

KÖSTER & CO. GMBH

Germany

The model K 24 is a robust stud welding gun, especially for studs ø 19 - 22 mm Ideal for welding shear connectors Ideal for through-deck-welding td High repeatability Hydraulic plunge damper Standard support with 2 legs Body made of fibre-glass reinforced polyamide Compensation for stud length variations up to 8mm Control cable plug (4 wire) Stud welding with shielding gas: optional

Request for a quote

KÖSTER & CO. GMBH

Germany

Best for stud welding using shielding gas ø 3 – 16 mm High repeatability Standard support with 2 legs Body made of fibre-glass reinforced polyamide Compensation for stud length variations up to 8mm Control cable plug (4 wire) Stud welding with shielding gas: optional

Request for a quote

ALPHA LASER GMBH

Germany

The ALFlak systems offer you many options in the field of mobile laser and repair welding. With an extended range and increased travel range, welding positions in deep, complex shapes can be processed easily thanks to the long laser arm - even in deep, bulky shapes. Deposition welding with wire or powder is possible with this laser machine. Likewise, automated welding tasks. The laser device is equipped with a fiber source that guarantees high efficiency and a special beam quality. Both pulsed and CW mode can be used. The integrated performance monitoring ensures reproducible welds. This system is available with laser powers of 300/450/600 and 900 watts.

Request for a quote

ALPHA LASER GMBH

Germany

This laser system is quickly set up for the welding task. The flexible laser arm can be rotated 360 ° and offers a very high or low working position. The laser head can be rotated to the left and right and the tilt-swivel lens directs the laser beam to the point desired by the operator. The robust housing has stable aluminum handles at the corners for increased impact protection of the edges. Integrated fastening options are available here for easy lashing during transport. The gas bottle can be transported during welding with a small trailer, the 5th wheel on the laser. Generous storage areas and special brackets on the machine sides ensure that tools, welding wire and whatever else is always within reach. Operation is intuitive via a touch display. Some apps help to weld surfaces, shafts and circular welds. The 450 W fiber laser can be used for pulsed welding or for welding in CW mode.

Request for a quote

EWM AG

Germany

— MMA inverter welding machine with degaussing function and reversing switch — MMA /MMA pulse — TIG lift arc / pulse — GMAW (MIG/MAG) welding with Pico drive 4L or Pico drive 200C wire feeder — Arcforce, Hotstart, Antistick — CC / CV characteristics — Suitable for flux cored wire welding — Welding polarity can be reversed by pressing the button polarity reversing switch — Stick electrode/MMA cellulose electrodes: 100% safe for vertical-down welding

Request for a quote

EWM AG

Germany

Compact inverter welding machine with integrated wire feed mechanism. Available with 3 different control variants: LP, HP, Expert 2.0. Can be retrofitted with optional modular water block Cool 50 U40 or tool box for storing welding accessories, e.g. welding torch. — Excellent Multimatrix welding characteristics — Equipped at no extra charge with Synergic characteristics for GMAW welding of steel/CrNi/aluminium — Equipped at no extra charge with EWM Synergic characteristics for forceArc, forceArc puls, rootArc, rootArc puls and superPuls — Suitable for MMA welding, TIG welding and gouging at no extra charge — 16 individually configurable programs for each welding task (JOB) — Large power reserves thanks to high duty cycle with all components heating up less as a result, guaranteeing a longer service life for machines when in use — Adjustable start and end crater functions — Synergic or manual welding mode

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== Copper Wire Scrap. grade 1 copper scrap not mixed with specification C11000 Electrolytic tough pitch Berry Copper (ETP) Content 99.9%. Cu%: 99.9% Element...0.005... (%) Copper..99.99... % (Min.) Lead...0.005.... % (Max.) Bismuth...0.5.. % (Max.) Total impurities...0.3.. % (Max.) Copper No. 2 kinds of alloy Wire cooper without lines, containing impurity, contain Copper quantity for 96% (minimum content 94%). Shall not contain excessive lead and tin change of copper wire, welding of copper, brass and bronze line, excessive oil, prohibition and nonmetal,crisp, burning line, utterly margin of fine copper and excessive sexual yarn. Need appropriate means to remove dirt. Birch Shall consist of clean, untinned, uncoated, unalloyed copper wire and cable, not smaller than No. 16 B & S wire gauge, free of burnt wire which is brittle

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

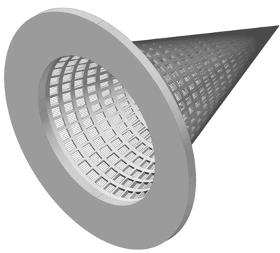

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quoteResults for

Wire welding - Import exportNumber of results

38 ProductsCountries

Company type