- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire cutting

Results for

Wire cutting - Import export

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

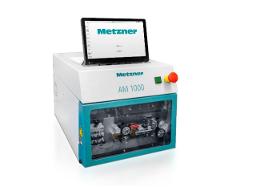

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® SD rounded cut wire shot is mainly used for cleanblasting and shot peening. Depending on the quality of the raw material used, different hardness classes are obtained. We supply non-corrosive cut wire shot that meet the requirement of particularly high demands. Cylindrical cut wire shot blasting abrasives are cut from wire. The length of the grain is equal to the diameter. Grain shapes of different roundness are produced through the subsequent rounding of the cylindrical raw material, rounded from G1 – G3. Cut wire shot has a particularly long service life and are known for low dust generation.

Request for a quote

ÖZKA MACHINE AUTOMATION

Turkey

Full Automatic Rewinding And Changing Unit Counter And Quantity Reporting Film Finish Sensor Coil Finish Sensor Cutting With Hot Wire Omron Plc Control System Omron 7" Touch Panel Omron Main Driver Mindman Pneomatic System

Request for a quote

ÖZKA MACHINE AUTOMATION

Turkey

Chanhing roll full automaticlly Total quantity and total meter reporting Stop auto. when paper core is finished Stop auto. when stretch film is finished OMRON PLC Control System OMRON 7" Touch Pane OMRON MAIN DRIVER MINDMAN PNUEMATIC SYSTEM Cutting with hot wire

Request for a quote

BORNEMANN GMBH

Germany

Special types are type stamps, which run through a special production, as the complexity of some shapes demands special production. Wire-cut or 5-axle special types for segments or segment stamping can be produced in every form. The selection of the materials is guided by the use.

Request for a quote

BORNEMANN GMBH

Germany

Roller die Roller die for the roller process of round work pieces with or without starting slope. These dies can be given flexible texts from individual insert milling or wire-cut excavations. The selection of materials depends on the relevant use. During production, we are guided by your drawings or data.

Request for a quote

SUZHOU CSL PRECISION CO., LTD

China

Our expertised engineers and technicians use advanced equipments like multi-axis CNC machining,CNC Turning, CNC Turning&Milling Combination, Grinding, Wire Cutting, CNC auotmatic Lathing/Swiss Machining to turn your designs into reality quickly, accurately and at a competitive price.

Request for a quote

STEEC

France

Since it was founded in 1979 STEEC offers, has been offering the service of machining parts for moulds and dies for all types of industries based on wire spark erosion cutting in particular. Because of this STEEC is recognized for its expertise in this field of activity both in France and in Europe as a whole.

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quote

STEEC

France

Spark erosion involves removing material from a conducting part and eroding it to give it the desired shapes and dimensions by means of electrical discharges. In the wire sparks erosion process an unwinding metal wire, under tension, is immersed in water or in another insulating liquid (dielectric) with the part to be worked. The current transmitted forms an electric arc which gives rise to precise, programmed degradation of a section of the part. The residues created by wearing of the part are removed by the water or dielectric liquid. STEEC carries out both spark erosion and fine wire micro spark erosion operations Wires spark erosion and machining Equipped with the latest wire spark erosion technologies, STEEC is able to carry high precision cutting with wires of standard sizes whose diameter may vary from 0.15 to 0.25 mm in all types of mechanical parts.

Request for a quote

KW HYDRAULIK GMBH

Germany

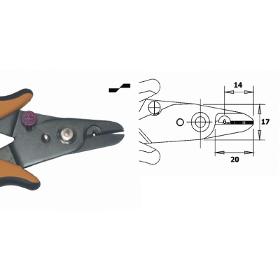

Wiring Duct Cutting Tool

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

Tweezers for cutting small wires, INOX, Length 95mm

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

Shear-wire stripper to cut Kevlar¨ and to strip optic fibres. Fixed at ¯ 0.18mm. Length 148mm

Request for a quote

KW HYDRAULIK GMBH

Germany

Bus Bar Working Stations for Bus Bars and Flat Material Punching Tools for Bus Bars and Flat Material Cutting Tools for Bus Bars and Flat Material Bending Tools for Bus Bars and Flat Material Brochure Tools for Control and Switchgear Cabinets Tools for Laminated and Flexible Bars and Earthground Sheet Metall Hole Puncher DIN Mounting Rail Cutting Devices Wiring Duct Cutting Tool Punching Tools for Sheat Metall

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-tai has the comprehensive processing capacity rolling, welding, NDT, leak test, heat treating sandblasting, painting, lathing, milling, boring, grinding, wire cutting, drilling, assembling. Hongfeng has 70 sets of various types of machining include 12 units of CNC boring & milling machine 5 units of CNC lathe. Advanced and perfect testing method provide good protection for quality control. Huan-tai also has long-term cooperation of many kinds of outsource supplier, such as forging, casting, and plating. So Hongfeng has enough capacity to achieve in different industry .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-tai has the comprehensive processing capacity rolling, welding, NDT, leak test, heat treating sandblasting, painting, lathing, milling, boring, grinding, wire cutting, drilling, assembling. Hongfeng has 70 sets of various types of machining include 12 units of CNC boring & milling machine 5 units of CNC lathe. Advanced and perfect testing method provide good protection for quality control. Hongfeng also has long-term cooperation of many kinds of outsource supplier, such as forging, casting, and plating. So Huan-tai has enough capacity to achieve in different industry .

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

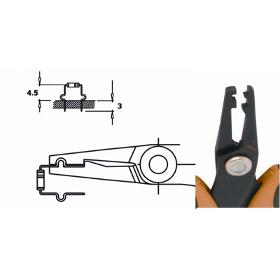

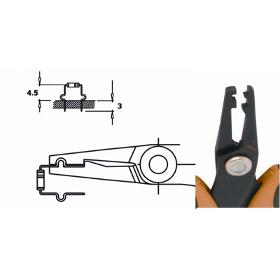

Forms the component wire in C-shape and cuts the residual part at 4mm. ESD. Steel thickness 3mm, Length 150mm

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Tool making & construction: The key to success We know the different industry-specific requirements for stamped parts and parts suppliers. Therefore, our day-to-day work includes very demanding tasks, which we overcome speedily and process reliably. Our spectrum of services for tool construction includes: 3D-CAD/CAM construction and programming (solid works, Peps, HSMworks) Wire-cut EDM (also contract manufacture) with workpiece sizes up to max. 600x400x350 mm Drilling erosion (start hole shooting) with workpiece sizes up to max. 250x350x300 mm Milling technology with workpiece sizes up to max. 650x500x500 mm Turning technology with workpiece sizes up to max. dm 210 x 1000 mm Flat grinding with workpiece sizes up to max. 600x300x375 mm and more…. Even complicated customer requirements are never a problem for us, but are instead a welcome challenge.

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

Forms the component wire in C-shape and cuts the residual part at 4mm. ESD. Steel thickness 3mm, Length 150mm

Request for a quote

SPIROL

Germany

The Series 550 Cosmetic Coiled Pin was designed specifically for cosmetic cases to ensure the perfect balance of strength and flexibility. The 1-1/2 coil construction ensures that the Cosmetic Coiled Pin exerts sufficient radial force to achieve the long-term desired swing torque while protecting the plastic from excessive stresses. The use of SPIROL Series 550 Cosmetic Coiled Pin will simplify your design and manufacturing process. Uniform radial spring force results in controlled hinge movement and a hinge quality that remains consistent over time. Controlled hinge movement is achieved with wider tolerances and lower moulding costs than when a Solid Pin or cut wire is used. Finally, low insertion force and compression of the pin during installation minimises hinge stress and scrap. The net result is the prolonged useful life of the assembly.

Request for a quote

FERPLAST SNC

Italy

TABLE MONOBLOC SEALER WITH MANUALLY OPERATED SEALING BAR AN INCORPORATED ROLL HOLDER The SP 600 is equipped with sealing bar with NI-CR wire for simultaneous cutting and welding of the film. Allows to obtain a polyethylene or polypropylene bag, perfectly welded and trimmed, using the normal fold film. Suitable for use in laundries, shirt factories, the textile sector in general, but is also suitable for the food sector for the packaging of the bread. Operation: Place the coil with the open side facing the operator Insert the open-film blade between the two flaps Unroll the film to the desired length Lower the sealing bar and cut the bag Enter the product in the bag and make the welding of the side remained open.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Trimmed for peak performance The construction industry is booming – and this has been the case for decades and all across the world. The need for new buildings, bridges and general infrastructure is constantly increasing. In terms of modern urban development, the demolition of buildings that are no longer up to date is part of everyday life. The stress on the tools used for this is easy to imagine. Demolition shears are used, for example, to cut angle iron or wire mesh, or to cut concrete ribs and steel rods. Our shearing knives or shear blades for mobile demolition shears are designed exactly for these massive stresses and have been used for many years on construction sites all over the world.

Request for a quote

VOM HOFE KALTSTAUCHDRAHT GMBH

Germany

11SMn30 - 1.0715 11SMnPb30 - 1.0718 11SMn37 - 1.0736 11SMnPB37 - 1.0737

Request for a quote

ROLF KÖRNER GMBH

Germany

Filter belts are used for a continuous filtration of polymer melt. These filter belts, but also wire mesh pre-cut parts, are manufactured in various dimensions and weaves. For high demands the fabrics are available with high tenacity warp wires. Plasma cut edges assure a continuous and frictionless passage of the filter belts Materials:Stainless steel, plain steel, combinations of various materials.

Request for a quote

RONIX GMBH

Germany

It is a small fella in huge industries like building and tower constructions, bridges, dams, steel structures, mines, etc. The high-grade Ronix Tower Pincer 10″ is a Ronix-designed hand tool made for gripping, twisting and cutting wires and nails in one operation. It is engineered and manufactured from hardened, precision Cr-V steel to cut edges of wires and pulling nails (with the help of its round head design) in any different applications. That is why it is an extremely durable product at construction sites and includes the best material to help extend the life of its grip.

Request for a quote

RONIX GMBH

Germany

Ronix Maxi RH-1368 Long Nose Pliers perform as expected of a long nose or needle nose plier. They are 8′′ (200mm) in size and allow operators to work precisely. The modern design of the jaws, as well as the hardened and tempered drop-forged steel and TPR handles, are just a few of the features that make these pliers ideal for bending, shaping, and cutting. Long nose pliers are unique in that they can bend, cut, and grip where fingers and other hand tools cannot. This hand tool could be useful for electricians, network engineers, jewelry makers, and anyone who needs to cut and bend wires, cables, and metalworks. Even if you're not on this list, you should have a pair of these long-nose pliers in your toolbox. To know more about RH-1368 scroll down and read the ‘detailed description’.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The electric cutting machine impresses with its compact build, quick processing times and flexible applications. Special features: Easy operation due to its 5“ display Simple insertion of wires Horizontal working level for improved insight into the operating area Guided conduction of cut wires Possibility to generate complete projects on the machine Optional extension for multiple infeed with the Z+F EVOFEED Full integration into the WPC is possible Multiple infeed Z+F EVOFEED By providing up to 12 conductors it is possible to sequentially process complex projects in a simple and effective way. The automatic feeding process makes manual interference obsolete and allows the processing of different cross-sections or colors according to the respective planning. This is very time-saving for the overall process, as individual jobs and projects can be processed autonomously.

Request for a quoteResults for

Wire cutting - Import exportNumber of results

111 ProductsCountries

Company type

Category

- Building hand tools, non-power (10)

- Industrial cutting machine tools (9)

- Mechanical engineering - custom work (7)

- Cutting, plastics - machinery (6)

- Machine tools, metal machining - parts and accessories (5)

- Milling - steels and metals (4)

- Steels and metals - surface treatment and coating (4)

- 3D scanner (3)

- Air disinfection - equipment and systems (3)

- Mining and quarrying - machinery and equipment (3)

- Tools, pneumatic (3)

- Electrical insulation (2)

- Metal industrial presses (2)

- Steel, carbon (2)

- Wire drawing and wire rod working machines (2)

- Wire rods - ferrous metal (2)

- Bearings, crankshaft (1)

- Biscuit making (1)

- Components and parts for small household appliances (1)

- Copper wires and cables (1)