- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spraying system

Results for

Spraying system - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® Spintec top loader spray chamber washing systems are the solution for fast parts cleaning in maintenance! The parts to be cleaned are placed in the washing basket of the system from above. During the washing process, cleaning fluid is sprayed onto the parts from below, above and from the sides. The basket rotates inside the machine, resulting in an even washing result. The detergent reservoir is located in the bottom of the machine and is also equipped with a heater.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

LALK GMBH &CO. KG

Germany

It has an integrated water spray system that ensures optimal saw blade cooling and immediate disposal of sawdust. Due to the extremely efficient working system the water consumption is low and it complies with current safety standards. Also the saw is very robust because of its welded steel construction. The table pad with non-slip rubber coating is also manufactured with great care and combined with the precisely running, easy-to-use cutting table with adjustable angle stop precise cuts are guaranteed.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

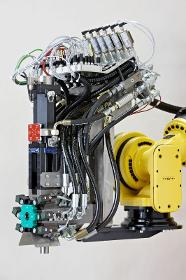

Eckardt Umformtechnik GmbH Contact-free lubrication Flexible & clean application Our spray systems apply oils and release agents fully contact-free. Making use of this method you guarantee the medium is applied cleanly and evenly, which allows you to act flexibly if not all areas of a material are to be lubricated uniformly. One huge advantage of our spray systems is their extremely fast changeover times to use different grades of oils. Oil/release agent storage; manual and fully automatic control and monitoring of the spray process. We offer our customers a wide range of options. Features & benefits • Minimum setup times when changing spray medium • Different spray nozzles available • Suitable for all fluid media and numerous oil grades Individual solutions for all application purposes EOS systems are perfectly designed to meet the needs of industry to apply oils and release agents. They are solidly built and exceptionally easy to maintain; they reliably and precisely control

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BENEFERT

Netherlands

BeneSOL 0-25-0 is a natural product of mineral origin subjected to an innovative physical process, without chemical alterations and an organic compatibility certification for application in organic production programs. The processing of the fertilizer increases the surface area and dispersibility, allowing it to be injected under agitation in all the different irrigation, fumigation and spray boom systems available on the market. Since it is categorized as dispersible powder it has a high agronomic effectiveness and reactivity. This product provides a high level of calcium and silicon, which is fundamental for the productivity and induction of the plant’s immune system and which improves the condition of the fruit and its post-harvest viability. This product is certified for use in organic agriculture in compliance with EC834/2007 and EC 889/2008.

Request for a quote

FRIMO GROUP GMBH

Germany

FRIMO PURe Mix mix heads are available as two-component or multiple-component mix heads for various PU product manufacturing. Different sizes for the smallest and the largest output rates are available. FRIMO offers a patented PU spraying system for the production of high quality PU surfaces, such as for automotive interiors.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TITANIUM The new generation of wave soldering systems – lead free soldering without corrosion. TITANIUM is the innovative soldering solution developed by STRECKFUSS SYSTEMS. It uses titanium, an agent which is extremely lead free solder resistant. For this reason, titanium works perfectly in lead free soldering processes. An oxide film immediately covers all material damages and thus prevents corrosion. In contrast to wave soldering systems with stainless steel components, titanium is not subject to corrosion even when lead free solder is used. By means of a simple and safe solder bath exchange, TITANIUM makes it possible to switch flexibly from a standard soldering process to lead free production. This ensures maximum flexibility at minimum costs and easy handling. TITANIUM is a complete system and includes: Spray fluxer with extraction hood Double wave 3- D wave (for the prevention of solder bridges) Infrared preheating Microprocessor controls Soldering frame transportation system

Request for a quote

PURASOL GMBH

Germany

Especially suited for filling of high viscosity pastes, creams, jellylike substances; no changing of the product because of the mechanical separation of the substance - in a flexible bag - from the propellant gas

Request for a quoteResults for

Spraying system - Import exportNumber of results

10 ProductsCountries

Company type