- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding technology

Results for

Welding technology - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

eim Klicken auf die Ergebnistabelle öffnet sich das entsprechende Datenblatt, bitte beachten Sie die Einträge für Basismaterialien im Datenblatt

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

The new non-copper-clad filler rods have excellent wire feed properties, also with very long hose packages and high wire advance speeds. The excellent current transition in the contact nozzle is achieved with these clean wire electrodes by wetting the surface by means of a special additive (takes over the function of the very-thin copper layer). This additionally provides for sufficient corrosion protection, also in case of storage over longer periods. The performance capability of this surface finish becomes clear particularly

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

A new generation of bright welding wires With the development of WDI PLATINARC, we have succeeded in combining the good properties of copper-plated and non-copper-plated welding wires. The Platinarc welding consumables are characterised by therefore by: Low contact tip wear Best wire feeding properties Minimal silicate precipitation in the weld sea Low splash formation Low copper content in welding fumes Stable electric arc

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

WDI's welding wire production at the Hamm/Westf. and Rothenburg/Saale /Wettin.Löbejün) sites can look back on a history of almost 50 years. Unalloyed and low-alloyed inert gas and submerged arc wire electrodes have been manufactured at WDI's main plant in Hamm/Westphalia since 1975 and at WDI in Rothenburg in central Germany since 1993. Production at both sites was gradually expanded and today, with a production capacity of up to 60,000 tonnes p.a., is one of the largest production facilities for welding wires in Europe. There is hardly a steel processing company in Germany or Europe that is not familiar with the wire electrodes from Hamm and Rothenburg. Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The future is lightweight – with Flexweld®. Flexweld®, the unique joining process, offers countless benefits, with one of the biggest advantages being the considerable weight reduction in the age of lightweight construction. Moreover, no additional machinery is required to incorporate it into an existing car body assembly line. significant weight saving, which provides long-term reduction in CO2 emissions joins lightweight materials to high-strength metals can be incorporated into existing assembly lines since it is possible to use the same production and welding equipment no additional qualification for workers needed complete system including full feeder and processing technology mixed production possible by adapting the spot weld gun software

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

In our workshop, welded assembly parts can be produced using TIG, MIG, MAG, Stainless and Aluminum welding technologies.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

In our workshop, welded assembly parts can be produced using TIG, MIG, MAG, Stainless and Aluminum welding technologies.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the pipe made by stainless steel 304,mainly use for the connector.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

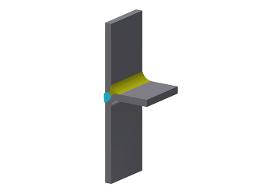

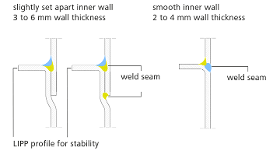

TECHNOLOGICAL INNOVATION OPENING UP NEW MARKETS The new automated Lipp welding process will again shake up tank construction market just as the well established Lipp double fold system did decades ago. It is a perfect combination of the long experience in metal forming and state of the art welding technology. KEY BENEFITS OF THE LIPP WELDING TECHNOLOGY Automated welding proces, on site Visual weld monitoring and technical documentation Reinforcement ribs for enhanced structural stability and reduced material costs High quality and repeatability Fast installation Choice of different material grades and types CERTIFICATES SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY BLACK STEEL SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY STAINLESS STEEL Beside black steel, various grades of stainless steel and duplex steel can be auto welded. In addition to the new potential markets and applications, the Lipp automated welding technology will increase the competitiveness

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our tasks also include joint process optimization with our customers in order to enable more efficient production and thus a reduction in set-up and downtimes. Our spooling systems are a good example of this type of cooperation and continuous further development. We connect the strips using state-of-the-art welding technology and rewind them oscillating on a variety of spools Strip widths from 1.5 mm up to 60 mm Extension of the strip length to more than 200,000 meters in one strip depending on the material Individual laying widths from 100 to 400 mm Special decoiling racks with decoiling widths of 800 mm and maximum decoiling weights of 2,500 kg

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our tasks also include joint process optimization with our customers in order to enable more efficient production and thus a reduction in set-up and downtimes. Our spooling systems are a good example of this type of cooperation and continuous further development. We connect the strips using state-of-the-art welding technology and rewind them oscillating on a variety of spools Strip widths from 1.5 mm up to 60 mm Extension of the strip length to more than 200,000 meters in one strip depending on the material Individual laying widths from 100 to 400 mm Special decoiling racks with decoiling widths of 800 mm and maximum decoiling weights of 2,500 kg

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP® Large Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The largevolume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. Speciality No additional nitrogen system necessary.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote

KASAG SWISS AG

Switzerland

Nonporous welding and sealing technology are the central criteria for building vacuum chambers and vacuum apparatuses. KASAG has specific knowhow that it has gained over many years as well as a great deal of experience. Comprehensive, internal tests, such as the helium-leakage test, guarantee the absolute leak-tightness of your KASAG products. With KASAG, you remain leak-proof.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR STORING BIOMASS TO BE USED FOR ENERGY PRODUCTION OR ANIMAL FEED The LIPP System is based on a world wide unique and genuinely simple principle of tank production. Steel coils, machines and accessories are transported to the construction site, the production of the tank takes place on site – fast, efficiently and flexibly in height and diameter. In an automated, two stage process, a profile is formed from the steel strip which is joined in a second step – at the same time, the container rotates spirally. The tight and stability supporting connection of the steel band can be effected by the LIPP Double Seam as well as the LIPP Welding Technology. Compact and space saving High functional safety Reduced retention time in the digester Reduced energy losses during storage Low maintenance and durable Automatic feeding Storage losses as a result of oxidation are avoided

Request for a quote

EC PLAZA

South Korea

GOGS CO., LTD. has received presidential award in 2008 for our patent technology at KINPEX. Our machine is highly specialized in heavy industry such as marine engineering, shipbuilding and etc. Our machine SHI(Samsung Heavy Industry), STX shipbuilding, Seongdong Shipbuilding & Marine Engineering, Hanjin Heavy Industries and etc. - 2-CORE control using PLC-CSI communication technology - High quality welding of 1mm thin plate at a distance (up to 100mm) - Lightening and decrease in failure rate using the All In One Cable - Multi-feeder that is possible to set operation conditions of a welding machine (Control of crater current and voltage, Power supply for auto carriage providing error messages) - Memory function of welding conditions - IoT function for smart control - Maximization of interlocking with auto welding machine (Smart welding Integration System(C-SWIS)

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

GUARANTEED OPTIMUM STORAGE FOR A WIDE VARIETY OF MATERIALS The storage of bulk materials needs to be not only cost effective but also safe, and systems should be easy to integrate in production processes. LIPP Double Seam technology and welded LIPP tanks have proven to be particularly suitable for bulk storage applications in industry and agriculture. LIPP silos provide a high level of stability and total leak tightness and protect bulk materials from moisture. The smooth internal walls of the silos are a benefit that pays dividends when storing special media. All kinds of bulk materials Grain Soya Silage fodder Woodchips Pellets Clinker brick Cement SILOS FOR STORING GRAIN AND OTHER FOODSTUFFS Grain, soya and other foodstuffs are precious commodities and a major asset in agriculture and they need to be stored particularly carefully. With the tried and tested Lipp Double Seam System, Lipp silos offer major benefits in terms of design and leak tightness.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our company specializes in a wide range of welding services, with an emphasis on high quality welding welds. We use modern technologies that guarantee excellent results. We carry out welding of a variety of materials, including carbon/structural steel, stainless steel and aluminum. Our production facility meets stringent quality standards, such as PN-EN ISO 3834-2:2007 and PN-EN 1090-2:2018-09. We have implemented modern welding technology for group 1.1 and 1.2 carbon steels in accordance with PN-EN ISO 15614-1:2017-08. Our skills include working with steels such as S355J2 and steels with lower yield strengths, especially for material thicknesses above 3 mm for fillet welds (3-23 for butt welds), welded using the MAG-135 method. We provide professional execution of any steel welding service.

Request for a quote

BASAK LAZER

Turkey

We offer welded construction solutions using gas metal arc, argon, MIG, TIG and Laser welding technology according to the requirements of our customers. Welding is the process of joining two or more materials with the effect of heat and/or pressure, with or without the use of additional materials. In addition to the joining process, the welding process is used in coating and filling processes. Today, there are many different welding methods. It is a type of process that is used extensively in the industry. Welded manufacturing is defined as a special process in international standards. For this reason, there are international standards in order to guarantee and level the quality level in welded manufacturing.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

WDI Spannstahl and its subsidiary nedri Spanstaal B.V in Venlo, Netherlands, are among the most important manufacturers of prestressing steel in Europe.The company has a recognised high level of expertise in the field of prestressing steel production. Since its foundation in 1925, NEDRI Spanstaal BV has gained a respected position and excellent reputation in the field of prestressing steel technology in Europe and far beyond.This expertise is a guarantee of top quality and sustainability when using our products for infrastructure projects, for onshore and offshore structures as well as in precast concrete construction. Our dedicated and experienced employees are the foundation for the perfection of our products. NEDRI Spanstaal BV is certified by Lloyd's Register Quality Assurance in accordance with ISO 9001 - 2008 and is a member of ESIS: European Stress Information Service.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quoteResults for

Welding technology - Import exportNumber of results

80 ProductsCountries

Company type

Category

- Wires and cables, steel (21)

- Tanks, metal (7)

- Welding work - steels and metal (6)

- Laser - cutting and welding machines (4)

- Textiles - Machines & Equipment (3)

- Industrial robots (2)

- Steels and metals - welding and brazing (2)

- Storage tanks (2)

- Welding robots (2)

- Welding, electric - equipment and supplies (2)

- Apparatus for gymnasiums (1)

- Autogenous welding machines (1)

- Construction, industrial - contractors (1)

- Diamond tools (1)

- Fences (1)

- Filtering equipment and supplies (1)

- Finished Metal Products (1)

- Food Processing (1)

- Harvesting machinery and equipment (1)

- Mechanical engineering - custom work (1)