- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding technology

Results for

Welding technology - Import export

HELAPET LIMITED

United Kingdom

Helapet offers unrivalled quality in the design and manufacture of our inline disc filters, both as off-the-shelf products or custom made specials. We supply filters for OEM and end-user applications in a wide range of markets including pharmaceutical, environmental monitoring, print, food and drink and electronics. Helapet strives to introduce added value to our filtration products, using consultancy based manufacturing and comprehensive testing to meet customer expectations. Our Vari-Disk® Service allows clients to select from a wide range of filter media, inlet/outlet connectors and housing sizes to best suit individual filtration requirements. Compliant to ISO 13485:2013, our membrane disc filters are in-house manufactured using the latest injection moulding and ultrasonic welding technology to deliver a top-quality product. All Helapet filters are tested before despatch and supplied with full lot traceability and certification.

Request for a quote

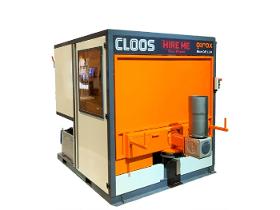

KEY PLANT AUTOMATION LTD

United Kingdom

High performance plug and weld robotic welding cells. Cost effective, production boosting and floor saving, the pay by the hour robotic welding cells are delivered ready to weld, simply plug and go – it’s as easy as that! All cells are two station, Loading whilst welding, and are protected by a light barrier and safety fence. Hassle free delivery – straight to your facility and workshops. With their one lift, easy to transport modular design, the robotic welding cells are delivered direct, hassle free to your facility. Pay by the hour rental Ready to use, plug and weld Cloos welding technology One lift, easy to transport Save production floor area

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

CTT has demonstrated outstanding expertise and an innovative spirit in the field of new energy vehicle chassis manufacturing. The company employs a range of advanced machining processes, from precision cutting and CNC bending to automated welding technology. Each step ensures high-performance and high-quality products. Additionally, professional surface treatment and precision machining of the chassis components further enhance the durability and reliability of the products. In terms of quality control, CTT has implemented a rigorous inspection process to ensure that every product meets high standards. After accurate assembly and comprehensive performance testing, CTT provides strong support for the chassis manufacturing of new energy vehicles, winning widespread trust and recognition from customers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Welding technology - Import exportNumber of results

3 ProductsCompany type