- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding engineer

Results for

Welding engineer - Import export

EMSIL TECHTRANS SRL

Romania

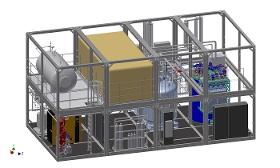

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards

Request for a quote

AAAGILER GMBH

Germany

Work clothes and protective workwear is more than just an outfit - it is your shield in demanding work environments and serves as a company's external image. Our exclusive collections of workwear offer a wide range of protective features that give you the safety, design and comfort you need. Whether you work in the chemical industry, welding, refrigeration, engineering, construction, skilled trades, offshore & marine, airports or other challenging tough jobs, our high quality clothing has been specifically designed to meet your health and safety needs and requirements.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

ILK IHRACAT AS.

Turkey

At steeling.net, we specialize in manufacturing top-quality heavy equipment blades designed to withstand the toughest conditions. Utilizing advanced laser cutting, CNC bending, and precise welding techniques, our blades are engineered for maximum durability and performance. Ideal for construction, mining, and agricultural machinery, these blades offer exceptional cutting efficiency and resistance to wear and tear. Each blade is custom-made to fit specific machine types and applications, ensuring a perfect match and optimal functionality. Our heavy equipment blades are crafted from high-strength materials, providing reliable and long-lasting solutions for your heavy-duty needs. Choose steeling.net for superior heavy equipment blades that enhance the efficiency and longevity of your machinery.

Request for a quote

MECASEM

France

Shot blasting is used for the production of metal parts subject to repetitive and cyclical stresses (landing gear, suspension parts, welding, engines, etc.). Faced with major safety constraints and problems of lightening the parts used, the interest of this technique is to be able to increase performance, slow down corrosion and increase the durability of the parts without increasing their weight. Our specialists can assist you in the development of your materials and products and in the control of industrial risks. At Mecasem, we have the latest shot blasting technologies at our disposal in order to best meet our customers' requirements. Our suspended load shot-blasting machine allows us to obtain a more varied range of impacts and opens up new perspectives for use.

Request for a quote

BAMBINA WORKWEAR

Turkey

High Visibility Reflective Work Jacket & Pants. Engineer pants with cargo and utilty pockets. Jackets can be designed for summer and winter seasons.

Request for a quote

DOREY

France

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant - a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Request for a quote

DOREY

France

The HG 50 is a versatile high-speed banner finishing machine engineered for welding, cutting, and grommeting operations all within a single station. Designed for a one-person operation, it eliminates multiple processes and minimizes material handling. This integration results in a significant increase in usable floor space and streamlines operations, optimizing both efficiency and productivity for businesses.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overhead cooling units for rail bound vehicles Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Assembly Test run Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

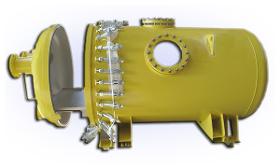

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Fittings made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Casing made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

The machine is manufactured in FMS’ production facilities and assembled at the end client’s site, including Mechanical and control systems design Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Internal assembly Test run at FMS’ facilities Assembly including hydraulics, pneumatics and electronics Control systems

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The rutile-basic-coated special-purpose electrode has a non-conductive and water-repellent coating for manual wet underwater welding. It is suited for assembly and repair welding in up to 20 m water depth for offshore and harbour construction, shipbuilding, and steel hydraulic engineering. High-quality welds require appropriate weld preparation, well-trained personnel, and compliance with recognised standards of good practice.

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

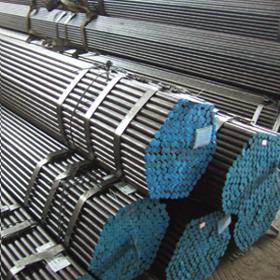

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

Bright steel EN 10278 The surface is significantly improved due to at least one additional work step – the primary material is beeing drawn, pickled or grinded for this purpose. The bending behaviour can be significantly improved due to additional heat treatment. Facts and Figures Diameter (OD)19,0 mm – 120,0 mm MaterialS235JRC S355J2 C15, C30, C45 other materials upon request Treatment condition+C, +SH, +SL (h7) +QT, annealed TestsUS testing (extra charged) ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quoteResults for

Welding engineer - Import exportNumber of results

29 ProductsCategory

- Machinery and equipment, used and reconditioned (5)

- Punching machine tools (4)

- Supply vessels (4)

- Flanges (2)

- Blades and knives, industrial (1)

- Casting, steel (1)

- Laser - cutting and welding machines (1)

- Machine tools - metal machining (1)

- Mechanical engineering - custom work (1)

- Pipes and tubes, stainless steel (1)

- Pipes and tubes, steel (1)

- Protective and work clothing (1)

- Shot blasting - steels and metals (1)

- Shotblasting materials (1)

- Spare parts for cars (1)

- Steels and metals - surface treatment and coating (1)

- Suits - men (1)

- Textiles - Machines & Equipment (1)

- Ultrasonic cutting machines (1)

- Welding, electric - equipment and supplies (1)