- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding engineer

Results for

Welding engineer - Import export

AAAGILER GMBH

Germany

Work clothes and protective workwear is more than just an outfit - it is your shield in demanding work environments and serves as a company's external image. Our exclusive collections of workwear offer a wide range of protective features that give you the safety, design and comfort you need. Whether you work in the chemical industry, welding, refrigeration, engineering, construction, skilled trades, offshore & marine, airports or other challenging tough jobs, our high quality clothing has been specifically designed to meet your health and safety needs and requirements.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overhead cooling units for rail bound vehicles Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Assembly Test run Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Welding Mechanical engineering Surface treatment Preassembly at FMS’ facilities Test run using weights Measuring vibration On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

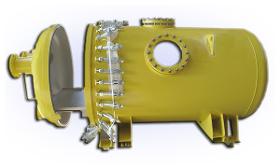

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Fittings made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Casing made of aluminium EN AW 6082-T6 Prefabrication of individual components High-grade, complex aluminium welding Mechanical engineering Flexural testing up to 170 KN Pressure testing Helium leak testing Bead blasting Partial surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

The machine is manufactured in FMS’ production facilities and assembled at the end client’s site, including Mechanical and control systems design Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Internal assembly Test run at FMS’ facilities Assembly including hydraulics, pneumatics and electronics Control systems

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The rutile-basic-coated special-purpose electrode has a non-conductive and water-repellent coating for manual wet underwater welding. It is suited for assembly and repair welding in up to 20 m water depth for offshore and harbour construction, shipbuilding, and steel hydraulic engineering. High-quality welds require appropriate weld preparation, well-trained personnel, and compliance with recognised standards of good practice.

Request for a quoteResults for

Welding engineer - Import exportNumber of results

15 ProductsCountries

Company type