- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vertical machine

Results for

Vertical machine - Import export

APD MAQMASTER

Spain

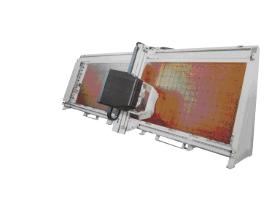

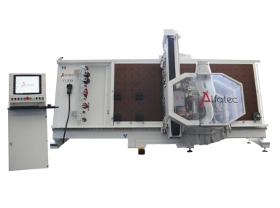

Three, four and five controlled axis configurations Bakelite work surface Extreme versatility to adapt to different materials such as PVC and plexiglass Working ranges: 3500×1600 – 2000 mm, 5000×1600 – 2000 mm, 6000×1600 – 2000 mm Work areas divided into 6/8/10 vacuum zones, automatically activated by the software according to the dimensions of the processed panels Benefits: Speed and precision in CNC machining of aluminum panels Greater comfort and productivity for operators Significant space savings compared to horizontal machines Versatility to work with a wide range of materials

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. Metalworking - CNC Vertical machine LX-0 5AX vertical linear motor machine, with automatic grease supply unit, in-process measurement function Renishaw MP-10 touch probe, Fanuc automatic measurement and alignment. Tool break detection and length measurement function (laser type) and automatic changer of the 3R system. Ott Jacob Tool Tensioners and 9 Tools.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

FERPLAST SNC

Italy

SEALING MACHINE/BAGGING MACHINE MOD. SUPER - FOR MASSIVE PRODUCTS Machine consists of a loading tube on which a tubular film with a width of 50 cm is fitted. and a manually operated sealing bar. The loading tube is slightly inclined and facilitates the sliding of the product inside the film, without causing sudden falls. By lowering the sealing bar a perfectly sealed bag is obtained and at the same time the bottom of the next bag is created, a hot cutting system separates the two packages. The SUPER bagging machine can be positioned at the entrance barriers of hypermarkets, supermarkets, shopping centers, to reduce theft, small objects but it is also widely used for packaging technical items, clothing, linen, etc.

Request for a quote

FERPLAST SNC

Italy

CHAMBER VACUUM PACKAGING MACHINE DZ 410 T - VERTICAL Vacuum packaging machine for packaging in vertical envelopes containing coffee, rice, tea, powder products, fluid products, etc. The machine is built in stainless steel (AISI 304) and equipped with an electronic volumetric sensor with 3 programs digital panel. The compact size chamber and the vacuum pump with a capacity of 20 m3/h. ensure high productivity. Also available with filter for packing powdery products such as hazelnuts flour, milk powder and products with similar characteristics. The filter must be requested at time of order. The packaging machine is equipped with a painted wheeled support. Max thickness bag mm. 0.20 (0.8 total with bellows). By equipping the machine with jigs realized according to the specific dimensions of the product to be packaged, it is possible to obtain squared packs. The templates are not included with the machine.

Request for a quote

FERPLAST SNC

Italy

FPXBAG-NEW is an innovative semiautomatic vertical packaging machine which combines different existing technologies with unique innovations. FPXBAG-NEW is an easy to use, economical and functional form-fill-seal machine which creates 3 hermetic sealing bags starting from a plain foil roll. Compared to the other vertical machines, FPXBAG-NEW has an innovative system of forming box which allows to get a fast format change. This systems reduces the machine shot-down and we gain in productivity. Moreover the two clamps of the horizontal sealing allow to keep the forming bag in position reducing the any break possibility. The key factor of the FPXBAG-NEW is the versatility of the machine which can seal any kind of film, this thanks to the incomparable sealing system. The machine is supplied with 1 forming tube type 200 (suitable for making bags with a width of 185 mm). On request it is possible to have forming tubes with different sizes, type 200 and type 250.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : 2018 CNC control : HEIDENHAIN iTNC 640 Number of simultaneous axes : 5 Stroke X axis : 2000 [mm] Stroke Y axis : 600 [mm] Stroke Z axis : 550 [mm] Feed rate on X, Y and Z axes : 20000 [mm/min] Traversing feeds X, Y and Z axes : 40000 [mm/min] Axes acceleration : 2.5 [mm/sec²] Min. distance spindle nose / table : 30 [mm] Table length : 1250 [mm] Table width : 800 [mm] Max. load on table : 500 [Kg] Rotary tilting table surface : 600 x 600 [mm] Stroke C axis : table revolution : 360 [°] Max. speed C axis : 25 [rpm] B axis swivelling stroke : -110 / +110 [°] Spindle type : ISO 40 Max. spindle speed : 15000 [rpm] Spindle power : 17 [kW] Tool changer magazin number of stations : 80 Max. tool length : 300 [mm] Max. weight of single tool : 7 [Kg] Total max. weight in tool changer magazin : 400 [Kg] Total power required : 57 [kVA] Supply voltage : 400 [V] Number of hours under power : 17840 [h] Weight : 15000 Kg

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2020 CNC control : HEIDENHAIN TNC 640 Number of simultaneous axes : 5 Stroke X axis : 650 mm Stroke Y axis : 850 mm Stroke Z axis : 500 mm Traversing feeds X, Y and Z axes : 36000 mm/min X axis ball screw, Ø x pitch : 40 x 12 mm Y axis ball screw, Ø x pitch : 40 x 12 mm Z axis ball screw, Ø x pitch : 40 x 12 mm Angular A axis stroke : +/- 120 ° Angular C axis stroke : 360 ° Min. distance spindle nose / table : 150 mm Max. distance spindle nose / table : 650 mm Spindle type : HSK-A 63 Max. spindle speed : 20000 rpm Tool changer magazin number of stations : 60 Max. tool length : 300 mm Max. weight of single tool : 8 Kg Total max. weight in tool changer magazine : 480 Kg Max. tool diameter : 125 mm Total power required : 60 kVA Number of hours under power : 5683 h Number of running hours : 3183 h Machine weight : 12000 Kg Machine dimensions : 3390 x 3940 x 2970 mm With equipment

Request for a quote

EMSIL TECHTRANS SRL

Romania

Perfect for vertical boring and milling

Request for a quote

EMSIL TECHTRANS SRL

Romania

Turning Machines Horizontal and vertical lathes

Request for a quote

FERPLAST SNC

Italy

Suitable for all types of neutral or printed film (preferably with antistatic treatment) or tubular polyethylene with thickness from 0.06 mm to 0.13 mm or tubular polypropylene with from 0.03 mm to 0.05 mm thick, and cartene normal or high density. Furthermore, with the FP BAG EVO it is also possible to use expanded polyethylene (FOAM) in tubular reel with a maximum thickness of 1.5 mm. It can use reels with a width of 80-300 or 100-500 mm without disassembly of parts or changing settings. The packaging machine automatically perform the forming of the bag with the upper opening. The filling of the bag and the subsequent closing can be done manually by an operator who starts the cycle of the machine through a button, or automatically by means of feeders, manipulators, weighers. The reel change takes a maximum of thirty seconds. The machine cycle time for the preparation of a bag 200 mm long is about four seconds.

Request for a quote

FERPLAST SNC

Italy

VERTICAL VACUUM SEALING MACHINE FOR BAGS - ALSO WITH MAP GAS INLET The sealers mod. DZQ 600 LS/DZQ 800 LS are multifunctional machines suitable for sealing and vacuum packing large bags and sacks, also in MAP (with technical gas injection). The vacuum pump of 20 mc./h. it minimizes air intake times and the machines are equipped with valves for the injection of inert gas for packaging in a modified atmosphere. The double sealing bars with a width of 10 mm. and compressed air closure ensure perfect sealing on any type of material, even of high thickness. The bars are closed by means of a double button command (dual safety control). The sack support surface is adjustable. Thickness max. bag mm. 0.20 (0.8 total with bellows) By means of selectors and potentiometers it is possible to set the "sealing", "empty time" and "gas injection time" functions. The machine is equipped with two nozzles which, when the vacuum option is activated, descend into the bag and perform suction.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-RL Vertical round bottle labeling machine is a self adhesive labeling machine design for round bottle labeling with single label pasting. It is original technology from Italy, high speed labeling and stable.The whole machine frame is adapt 304 stainless steel,servo motor driven the labeling head, PLC control,frequency speed adjust.The labeler can equip with a date coder for printing date, LOT number, also bar code.The detection function is as an option, such as automatically rejection for missing label,automatic warning on missing label, automatic rejection for no date printing etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STATEC BINDER GMBH

Austria

The SYSTEM-F, a fully automatic vertical form-fill-seal packaging machine, produces pillow bags and gusset bags with or without carrying handle and a filling weight between 5 kg and 50 kg from flat film. The System-F is particularly ideal for packaging powdery and moderately free-flowing products. Thanks to an adjustable format set, different package sizes can be produced. The format and/or production can be changed by one person in just a few minutes. This is made possible by a rotating magazine, which is installed directly on the machine and holds several format sets of different sizes ready at all times. The vertical FFS packaging machine impresses with its compact design and low space requirement. Further options allow this bagging machine to be adapted to a wide range of requirements.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Robust and extremely low maintenance Powerful Variable strap width ASLF 'Anti-Strap-Loss-Function' Constant strap control Automatic Strap feed Strap width 5 - 12 mm, either Operation Terminal with Soft-Button DAT 'Direct-Access-Technology' Torque controlled strap tension, adjustable GreenTech energy concept, low power consumption Intuitive operator interface OPTIONAL: Machine movable Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

FERPLAST SNC

Italy

The PANDYNO FPPD vertical inserters allow to an operator to fill and seal the packs avoiding the use of preformed bags. The operator must in fact insert the product to be packaged in the magazine tube, on which a few meters of tubular film have been previously loaded. The product goes down into the tubular film up to the support surface. The operator manually closes the sealing bar by applying a slight pressure on the bar. The welding machine in a single operation carries out the welding of the package, the cutting of the film and the welding of the bottom of the next envelope. This operation takes place using an electromagnetic blocking device. By equipping the bagging machine with several loaders, it is possible to increase the productivity of the machine. To avoid waiting times it is also possible to pre-load different magazine tubes so that they can be quickly replaced once the film is finished. The standard model can be placed on a bench and comes with a charger of your choice.

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Industrial Robot Intelligent Production Horizontal Machining High-precision Testing The production facility is equipped with more than 400 sets of horizontal machining centers, vertical machining centers and high speed CNC, mainly Mazak, Nachi-Fujikoshi and Doosan. Our company is approved by ISO9001 quality management.

Request for a quote

APD MAQMASTER

Spain

Vertical CNC woodworking machines with closed table. Vertical CNC machines with three, four and five controlled axes equipped with a fixed Bakelite work table. Suitable for any type of processing, recommended for those who work a lot of panels, since the closed top technology allows both suction cup and nesting operations

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : CNC control :HEIDENHAIN iTNC 530 Number of simultaneous axes : 5 Stroke X axis : 600 [mm] Stroke Y axis : 450 [mm] Stroke Z axis : 450 [mm] Table length : 325 [mm] Table width : 325 [mm] Max. load on table : 200 [Kg] Table surface Ø : 450 [mm] Spindle type : HSK-A 63 Min. spindle speed : 100 [rpm] Max. spindle speed : 20000 [rpm] Spindle power : 13.5 [kW] Tool changer magazin number of stations : 120 Max. tool lenght : 250 [mm] Max. weight of single tool : 6 [Kg] Max. tool diameter : 125 [mm] Supply voltage : 400 [V] Machine weight : 7700 [Kg] ATC weight : 800 [Kg] Automatic Pallet Changer weight : 1200 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Hermle Model C1200V Year 1999 Condition Used Made in Germany Control Unit Heidenhain 530 X-axis travel 1200 mm Y-axis travel 900 mm Z-axis travel 500 mm Table size 700 x 900 mm Number axis 3 Spindle speed 16000 rpm Tool change unit 30 Dimensions L 4000 x W 3500 x H 3500 mm Weight 12000 Kg

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Stama Model MC 010 Year 1990 Condition Used Control unit Fanuc O - M X-Axis travel 500 mm Y-Axis travel 380 mm Z-Axis travel 330 mm Table length 650 mm Table width 380 mm Table load 200 kg Spindle taper SK 30 Spindle speed 6000 rpm Motor power 5.5 kW Tool magazine 10 places Dimensions L 2000 x W 1600 x H 2500 mm

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Huron Model K2X8 Five Year 2006 Condition Used Made in France Control unit Siemens 840D X-axis travel 650 mm Y-axis travel 700 mm Z-axis travel 450 mm A-axis travel -45°/+180° C-axis travel 360° Spindle table angle 0°/90° Table diameter 500 mm Maximum workpiece weight 250 kg Spindle taper HSK-63A Spindle speed 24.000 rpm

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC milling with 3-axle by vertical machining centres of up to 2000x500x600 mm; - CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC milling with a 4-axle vertical machining centre of up to 2000x540x440 mm.

Request for a quoteResults for

Vertical machine - Import exportNumber of results

164 ProductsCountries

Company type

Category

- Machine tools - metal machining (32)

- Food industry packaging machinery (25)

- Laser - cutting and welding machines (10)

- Packing and packaging - machinery and equipment (10)

- Food packaging (5)

- Milling - machine tools (3)

- Milling - steels and metals (3)

- Paper - Printing - Machines & Equipment (3)

- Balancing machines and systems (2)

- Custom packaging (2)

- Cutting - steels and metals (2)

- Machine tools, metal machining - parts and accessories (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Package sealing machinery (2)

- Steels and metals - machining (2)

- Adjustment - machine tools (1)

- Agglomeration and emulsification machines for the food processing industry (1)

- Agriculture - Machines & Equipment (1)

- Aluminium alloys (1)

- Boring, plant and equipment (1)