- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum coating

Results for

Vacuum coating - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Mid-frequency magnetron sputtering technology has gradually become the mainstream of sputtering coating technology. Coating: Multi-function metal coating, composite membrane, transparent conductive coating, Increase return to shoot coating, electromagnetic shielding coating, decorative coating, etc. Power supply: DC magnetron sputtering power supply, MF sputtering power supply, high pressure ion bombard power supply. Target: DC magnetron sputtering target, MF twin targets, planner target, cylinder target. Vacuum chamber structure: Vertical signal door, Vertical double doors. Pump system: Molecule pump (diffusion pump)+Roots pump+ Holding pump(optional: turbo pump, poly cold system) Air system: Mass flow controller (1-4road) Ultimate vacuum: 6x10-4pa (no-loading, clean chamber) Pumping time: No-loading from air to 5x10-3pa<13mins Workplace motion mode: 6 axis/8axis/9axis public and self-rotation

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Shoes Heel Vacuum Coating Machine/Shoe Heel Metallizing Plant/shoe Heel Metallization Machinery

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

We use this vacuum degasser to clean all kinds of products before do the coating. This degas chamber is venting the gas,air and other impurities through putting in the heated N2. This vacuum degasser will greatly shorten the vacuum time, reduce the oxygen corrosion, protect the machine and prolong the life time of the equipment. It enhances the adhesion of the film in the products.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Jewelry ion spray chrome Coating machine/jewelry pvd vacuum coating equipment,pvd plating machine

Request for a quote

HEAVYDRIVE GMBH

Germany

Coated and vapour coated panes etc. are delicate therefore we have special non rub off suction plates for all our vacuum lifting devices ready for residue free handling. Non-marking plates leave no traces on vapour coated or mirrored panes for instance.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

SolarPaq® temperature profiling systems are designed for specific use in solar photovoltaic (PV) manufacturing. These systems, consisting of user-friendly Insight™ software, Datapaq® Q18 data loggers, stainless steel thermal barriers, thermocouples with PTFE or mineral insulation and accessories, provide you with the tools required to obtain the highest production yields. The Datapaq Q18 logger features rugged, reliable and accurate data acquisition circuits, clear status indicators and an intelligent battery management system. It also features start/stop buttons, time or temperature trigger, memory capacity of 300,000 readings and measures wide temperature ranges from -200°C to 1370°C/-328°F to 2498°F. SolarPaq Profiling System for CiGs Panel Coating SolarPaq temperature profiling system for CiGs Panel Coating monitors the glass substrate as it passes through the vacuum coating process. Its core, the DQ1840 datalogger, is housed

Request for a quote

INFICON GMBH

Germany

THE STANDARD IN GAS ANALYSIS Excellent Performance and Great Value for General Vacuum Applications As manufacturing technologies advance and quality standards change, the need to understand your process and maintain product quality is more important than ever. Transpector MPS can help you optimize your process by monitoring process conditions, detecting contaminants, and checking for leaks. Transpector MPS offers the robust performance of the Transpector brand of RGA at an excellent value for our customers. Transpector MPS is available in both 100 amu and 200 amu versions, which gives you the flexibility of performing a wide variety of functions including general leak detection, vacuum diagnostics, and hydrocarbon analysis. This versatility makes Transpector MPS the sensor of choice for vacuum furnace, heat treating, and vacuum coating applications. (1) at 10% of peak height (2) during an eight hour period, after a half hour warm up; in FC mode only (3) 256 millisecond dwell time

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

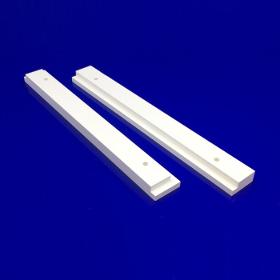

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

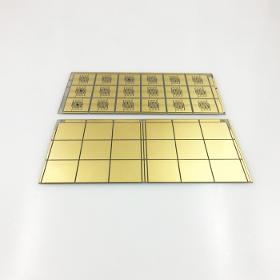

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China plastic casters swivel wheel supplier, Soruce factory with lowest prices. Plastic casters swivel wheel, nylon casters with brake, locker process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China injection molding factory custom all kinds of plastic products for world clients. Plastic wheel project: Plastic wheel barrow wheel process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

screw and barrel for rubber extruder Material: HVOF Spray Coating Screw, PTA Spray Welding Screw, Nitriding Screw Application: For use in the Injection Moulding Machine , Extrusion Moulding Machine, Bakelite Moulding Machine, and Rubber Moulding Machine. Processing Dimension:Min External Diameter Ø 12mm, Max External Diameter Ø 250mm,Effective length Ø 8000mm . Machining SCREW Heat-treatment, Nitriding treatment, Electroplated hard-chrome finish, High-frequency quenching, Spray coating bimetallic-alloy, Vacuum quenching. Customer’s specification and drawing are accepted in the manufacturing various materials of pillars, columns, tie bars, guide rods which applicable to various plastic, rubber injection molding machine, hydraulic machine, diverse machine tool etc. (Special dimension and spec. are also acceptable. )

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

Aluminum mirror, silver mirror, gold mirror, deflection mirror

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

Aluminum mirror, silver mirror, gold mirror, deflection mirror

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our anti reflective coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, anti reflective glass, AR coating

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

Using selected low-loss, self-healing polypropylene films and sophisticated manufacturing techniques such as high-vacuum drying and special coating patterns, the best of ELECTRONICON™s design expertise and highest care in manufacturing have been spent to prepare these capacitors for your most demanding applications, and toughest ambient conditions. Our long-life MKP UHDTM contain three delta-switched capacitor elements of short height and large diameter. The optimized combination of winding length, film size, and winding geometry substantially reduces inherent power losses and allows us to achieve highest surge and rms current ratings as well as an overvoltage strength and switching stability which before would have been known only of impregnated paper capacitors. An MKP UHD™ handles up to 250% of its rated current and current surges of 400 x IN. The permitted operating temperatures range from -40°C up to 70°C maximum temperature (average over 24 hours: 60°C).

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Parylene is the short name for the polymer group of poly-para-xylylene. Parylene coatings offer a wide range of benefits. Parylene ... are fully conformal: i.e. they adapt to complex substrate contours such as sharp edges, drill holes or blind holes are pinhole-free from a film thickness of approx. 0.5 µm. are chemically insoluble and resistant to a wide range of chemicals. have very good barrier properties against moisture and chemicals. have a high dielectric strength. have dry lubricating properties (low coefficient of friction). are hydrophobic: contact angle of H2O between 92 ° and 98 °. are transparent between 90 and 96 % in the visible wavelength range (depending on type). are biocompatible: types C and N parylene can be deposited, which can be certified according to USP Class VI, ISO 10993 and FDA.

Request for a quote

VACUUM EL SYSTEM LTD.

Bulgaria

Vacuum El System offers powder coating service for a variety of parts, ranging from small components to large metal cabinets and constructions. Parts are painted according to their application with either epoxy-polyester or polyester powder, utilising the latest technology and equipment from Wagner. Prior to painting all parts go through pre-treatment process to ensure their surface is clean, degreased and phosphated. Strict quality control checks coating thickness, structural integrity, gloss level and visual appearance. Our automated paint booths ensure a fast turnaround and high throughput of powder coated components. Maximum booth capacity is 4100mm x 1600mm x 2500mm and 800kg.

Request for a quoteResults for

Vacuum coating - Import exportNumber of results

22 ProductsCountries

Company type