- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum coating

Results for

Vacuum coating - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Mid-frequency magnetron sputtering technology has gradually become the mainstream of sputtering coating technology. Coating: Multi-function metal coating, composite membrane, transparent conductive coating, Increase return to shoot coating, electromagnetic shielding coating, decorative coating, etc. Power supply: DC magnetron sputtering power supply, MF sputtering power supply, high pressure ion bombard power supply. Target: DC magnetron sputtering target, MF twin targets, planner target, cylinder target. Vacuum chamber structure: Vertical signal door, Vertical double doors. Pump system: Molecule pump (diffusion pump)+Roots pump+ Holding pump(optional: turbo pump, poly cold system) Air system: Mass flow controller (1-4road) Ultimate vacuum: 6x10-4pa (no-loading, clean chamber) Pumping time: No-loading from air to 5x10-3pa<13mins Workplace motion mode: 6 axis/8axis/9axis public and self-rotation

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Shoes Heel Vacuum Coating Machine/Shoe Heel Metallizing Plant/shoe Heel Metallization Machinery

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

We use this vacuum degasser to clean all kinds of products before do the coating. This degas chamber is venting the gas,air and other impurities through putting in the heated N2. This vacuum degasser will greatly shorten the vacuum time, reduce the oxygen corrosion, protect the machine and prolong the life time of the equipment. It enhances the adhesion of the film in the products.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Jewelry ion spray chrome Coating machine/jewelry pvd vacuum coating equipment,pvd plating machine

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

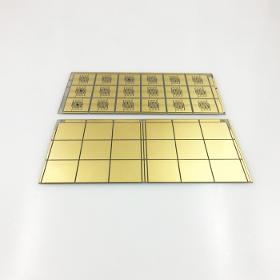

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China injection molding factory custom all kinds of plastic products for world clients. Plastic wheel project: Plastic wheel barrow wheel process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China plastic casters swivel wheel supplier, Soruce factory with lowest prices. Plastic casters swivel wheel, nylon casters with brake, locker process: plastic injection molding materials :Abs,POM, PVC,PC, polyethylene, nylon 6, nylon 66, polypropylene, copolymerized polypropylene, polyester, PD-PE, NBR, etc. Surface treatment: Deburring, ABS Chrome plated, vacuum coated etc. We are a professional plastic injection molding manufacturer from Ningbo China, we customize a variety of plastic wheels for all industries.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

screw and barrel for rubber extruder Material: HVOF Spray Coating Screw, PTA Spray Welding Screw, Nitriding Screw Application: For use in the Injection Moulding Machine , Extrusion Moulding Machine, Bakelite Moulding Machine, and Rubber Moulding Machine. Processing Dimension:Min External Diameter Ø 12mm, Max External Diameter Ø 250mm,Effective length Ø 8000mm . Machining SCREW Heat-treatment, Nitriding treatment, Electroplated hard-chrome finish, High-frequency quenching, Spray coating bimetallic-alloy, Vacuum quenching. Customer’s specification and drawing are accepted in the manufacturing various materials of pillars, columns, tie bars, guide rods which applicable to various plastic, rubber injection molding machine, hydraulic machine, diverse machine tool etc. (Special dimension and spec. are also acceptable. )

Request for a quoteResults for

Vacuum coating - Import exportNumber of results

10 ProductsCountries

Company type