- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum brazing

Results for

Vacuum brazing - Import export

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

NKCG engineering configures solution optimized for the specific heat treatment process using FEA/CFD and other advanced tools. NKCG systems are being used in various applications such as Carburizing | LPC | Sintering | PVD/CVD | Vacuum Brazing | Inert gas and vacuum atmospheres

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic-to-Metal Seal The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Controlled Atmosphere Brazing (CAB) and Vacuum Furnace Tracker Systems from Fluke Process Instruments feature the Datapaq TP6 data logger, a reflective or sealed for CAB thermal barrier, thermocouples and our intuitive Insight™ Software to create a complete solution. The CAB Furnace Tracker Systems featuring the TB4000 & TB4002 thermal barriers operate in environments up to 800°C (1472°F) and are designed for frequent use in the aggressive atmosphere present in this process. The Vacuum Brazing Furnace Tracker Systems, which include the VB1150 & VB1151 thermal barriers, make use of reflective plate technology to eliminate the need for insulation and ensure that out-gassing from the system is minimized so production is not disrupted when profiling. Both systems can be used to conduct temperature uniformity surveys (TUS) in compliance with CQI 29. Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

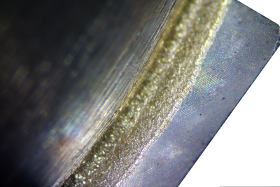

Thanks to decades of experience and innovation, the Tyrolit range includes drill bits, including TGD® technology diamond wet drill bits, which fulfil almost all construction requirements. Especially in combination with Tyrolit drill motors, they offer reliable and clean results. Tyrolit fulfils the expectations of construction professionals with durable wet core bits for precise core drilling in various dimensions. — For reinforced concrete, steel, masonry, brick, sand-lime brick, fireclay brick, asphalt and special applications — Holders and connection threads in accordance with local standards for all motor types — Perfect system solutions with Tyrolit drill motors and drill rigs — Special dimensions and customised solutions on request Tyrolit offers vacuum-brazed diamond tile drills for wet and dry drilling (with paraffin), which enable precise drilling without edge chipping in tiles, porcelain stoneware and marble slabs.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

For wet and dry drilling of tiles and ceramics, Tyrolit offers vacuum-brazed diamond tile drills that guarantee maximum drilling comfort and clean results. Our products enable precise drilling without edge chipping, even with hard materials. Wet drilling: Specially developed for ceramic tiles, porcelain stoneware and marble slabs, these drill bits ensure precise results thanks to optimum wetting of the diamonds with water. Dry drilling: Tile drill bits with paraffin filling offer excellent cooling and clean working. Drill bit sets: Tyrolit offers drill bit sets for tiles that contain everything you need for wet and dry drilling, including accessories such as a water bottle, drilling aid and tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing /Innovacera Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

WIGTEC FISCHEREDER KG

Germany

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ TP3 data logger * 10 or 20 thermocouple channels * Temperature range: -100 °C – 1370 °C/-148 °F – 2498 °F * Sample interval: 0.1 sec – 50 min without telemetry; 1 sec – 50 min with RF radio data transmission * Memory: 3.6 million data points * Robust stainless-steel machined case * High logger accuracy: ±0.3°C (±0.5°F) Comprehensive thermal barrier range for * Heat treatment and TUS * Vacuum carburizing and vacuum heat treatment * Aluminum solution treatment and age hardening * Steel slab and billet reheat * Controlled atmosphere brazing * Aluminium vacuum brazing Specialized software for TUS applications is trusted by hundreds of our customers to meet the stringent requirements of AMS2750E and CQI-9 certifications. Fluke Process Instruments offers a wide variety of PTFE, glass fiber or mineral insulated thermocouples to withstand harsh environments and high temperatures, conforming to the highest standards and providing the most accurate data possible.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Heat Treatment furnaces MOV are ideal for the treatment of sophisticated materials if high temperatures and an absolutely clean hydro-carbon free atmosphere are required. Due to the ultrahigh vacuum atmosphere as well as the extreme temperature homogeneity and the fully automatic process the furnaces are especially suitable for the economic application in industrial and medical productions, i.e. for brazing of vacuum interruptors, parts of x ray tubes, heat exchangers, parts used in the medical and aerospace industry. Applications: MOV furnaces are universally applicable if heat treatment with particularly high requirements in respect of cleanliness for exacting materials is involved, for example: • Degassing of electric or radiation tube components • Bright- and stress-free annealing of high-temperature alloys • Sintering of high-melting and heavy metals such as tungsten • Production of high-quality fluxless braze joinings of steels, steel-ceramics and many other materials.

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

For dry use on angle grinders.

Request for a quote

ARUP ALU-ROHR UND PROFIL GMBH

Germany

Our charge air cooler tubes help you meet the requirements necessary to comply with today’s evolving emissions regulations. Whether you need a standard or custom profile, our tubes are tailored to provide the performance and durability required by today’s turbocharged engines. • Profiles from 30 mm to 85 mm in tube height • Metal strip gauges as thin as 0.35 mm • A wide array of aluminum alloys for both CAB and vacuum-brazing applications

Request for a quote

INTERLINEX B.V.

Netherlands

Air pressure: 90 – 120 PSI Air consumption: 180 L p/min Tank capacity: 0,75L + 1L Air Inlet: 1/4"

Request for a quoteResults for

Vacuum brazing - Import exportNumber of results

14 ProductsCountries

Company type

Category

- Ceramics, industrial (3)

- Drilling machinery (2)

- Drill bits and countersinks (1)

- Electric vehicles (1)

- Electroheat - machines and equipment (1)

- Heat treatment furnaces (1)

- Infrared tubes (1)

- Pipes and tubes, aluminium (1)

- Steels and metals - machining (1)

- Temperature sensing devices (1)

- Vacuum cleaners - industrial (1)