- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum brazing

Results for

Vacuum brazing - Import export

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

NKCG engineering configures solution optimized for the specific heat treatment process using FEA/CFD and other advanced tools. NKCG systems are being used in various applications such as Carburizing | LPC | Sintering | PVD/CVD | Vacuum Brazing | Inert gas and vacuum atmospheres

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

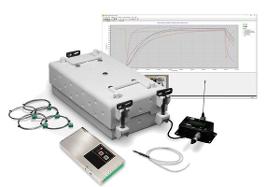

The Controlled Atmosphere Brazing (CAB) and Vacuum Furnace Tracker Systems from Fluke Process Instruments feature the Datapaq TP6 data logger, a reflective or sealed for CAB thermal barrier, thermocouples and our intuitive Insight™ Software to create a complete solution. The CAB Furnace Tracker Systems featuring the TB4000 & TB4002 thermal barriers operate in environments up to 800°C (1472°F) and are designed for frequent use in the aggressive atmosphere present in this process. The Vacuum Brazing Furnace Tracker Systems, which include the VB1150 & VB1151 thermal barriers, make use of reflective plate technology to eliminate the need for insulation and ensure that out-gassing from the system is minimized so production is not disrupted when profiling. Both systems can be used to conduct temperature uniformity surveys (TUS) in compliance with CQI 29. Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek-MicroCoil 1.3 x 2.3 mm used in the "Brazed-Together" energy-saving nozzle heater is wound tightly onto a precision tube with good thermal conductivity and encapsulated and thermally insulated by means of an outer housing. For even more reliable heat transfer, the heater can optionally be vacuum brazed. The "Brazed Together" design combines many advantages: high accuracy, good heat conduction, high power density, mechanical stability and, last but not least, up to 20% higher energy efficiency. Freek is one of the technology leaders in the field of hot runner heating and supplies the who's who of the industry. Energy efficiency is one, if not the central innovation topic here. Manufacturers of high-cavity PET hotrunners and moulds in particular benefit from the BT nozzle heaters, and in several ways: because the less energy that is put into the system, the less energy has to be taken out on the cold side, the mould. This saves even more energy and shortens the cycle time.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

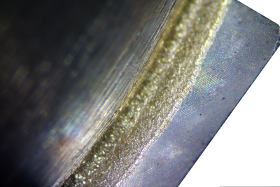

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ TP3 data logger * 10 or 20 thermocouple channels * Temperature range: -100 °C – 1370 °C/-148 °F – 2498 °F * Sample interval: 0.1 sec – 50 min without telemetry; 1 sec – 50 min with RF radio data transmission * Memory: 3.6 million data points * Robust stainless-steel machined case * High logger accuracy: ±0.3°C (±0.5°F) Comprehensive thermal barrier range for * Heat treatment and TUS * Vacuum carburizing and vacuum heat treatment * Aluminum solution treatment and age hardening * Steel slab and billet reheat * Controlled atmosphere brazing * Aluminium vacuum brazing Specialized software for TUS applications is trusted by hundreds of our customers to meet the stringent requirements of AMS2750E and CQI-9 certifications. Fluke Process Instruments offers a wide variety of PTFE, glass fiber or mineral insulated thermocouples to withstand harsh environments and high temperatures, conforming to the highest standards and providing the most accurate data possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARUP ALU-ROHR UND PROFIL GMBH

Germany

Our charge air cooler tubes help you meet the requirements necessary to comply with today’s evolving emissions regulations. Whether you need a standard or custom profile, our tubes are tailored to provide the performance and durability required by today’s turbocharged engines. • Profiles from 30 mm to 85 mm in tube height • Metal strip gauges as thin as 0.35 mm • A wide array of aluminum alloys for both CAB and vacuum-brazing applications

Request for a quoteResults for

Vacuum brazing - Import exportNumber of results

7 ProductsCountries

Company type