- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding

Results for

Welding - Import export

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing offers a range of welding solutions including MIG welding, TIG welding, robotic welding, projection welding and spot welding for aluminium, mild steel and stainless steels. Our highly trained weld team are some of the best in the industry and our quality is second to none. Robotic Welding Alpha Manufacturing's installation of a robotic welding has increased our capacity to offer high accuracy weld detail in volume as well as 100% product repeatability. Robotic Welding is the perfect solution for customers who require high volume, highly accurate, repeatable products. Alpha's robot welder boasts high-end features such as Cold Metal Transfer technology to eradicate spatter and reduce burn-through and distortion. The Robot also comes equipped with Seam Finding technology to ensure the robot always welds true to joining parts.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Enhance your automated welding processes for inner, outer, circumferential and longitudinal welding applications with Key Plant column and boom welding manipulators. Key Plant column and boom manipulators are developed to upgrade your fabrication throughput, and augment the quality of your weld production. We supply machines for a range of manufacturing environments; from pipe fabrication shops to tanker assembly lines, Key Plant provide the best solution to suit your project requirements. Key Plant have built a portfolio of global leading column and boom welding manipulators, available to buy, rent or lease. Our range consists of Mobile Pipe, Standard, Extra-Heavy and Telescopic models. But if your project demands are non-typical, our in-house capabilities and next-level engineering expertise enable us to develop special purpose machines for those more ‘complexed’ project needs.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

The ultimate cobot welding system available to buy and hire. ‘Ready to weld’ complete package The cobot welder includes all components being necessary for automated welding – perfectly matched to each other and easy to mount. The compact ” Ready to weld” cobot package is delivered completely ready for operation which ensures a problem-free integration into existing production processes. Exact, intuitive and safe A torque sensor in each axis allows the Cobotto be programmed and moved precisely. The intuitive operation significantly increases work efficiency. The user can make individual adjustments on the user-friendly touch control panel with macros specially developed for welding. In addition, the Freedrive option with foot switch and the intelligent safety concept guarantee sensitive and safe control of the cobot welder. Another special feature is the simple restart after an emergency stop as no extensive unlocking or free movement of the robot is necessary.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

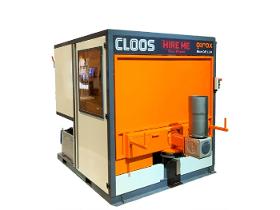

High performance plug and weld robotic welding cells. Cost effective, production boosting and floor saving, the pay by the hour robotic welding cells are delivered ready to weld, simply plug and go – it’s as easy as that! All cells are two station, Loading whilst welding, and are protected by a light barrier and safety fence. Hassle free delivery – straight to your facility and workshops. With their one lift, easy to transport modular design, the robotic welding cells are delivered direct, hassle free to your facility. Pay by the hour rental Ready to use, plug and weld Cloos welding technology One lift, easy to transport Save production floor area

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Our heavy duty, built to last conventional welding rotators are designed and manufactured to tolerate the hardest, hard-wearing and unrelenting workload environments. The powered drive units are controlled by a five-function pendant with a variable speed potentiometer, giving the operator full control of the rotating workpiece. Available to buy and hire Comprehensive stocks Up to 500 tonne capacities Worldwide delivery

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANOPOL LTD.

United Kingdom

Stainless steel derives its corrosion resistant properties from a thin oxide film on the surface, often referred to as a passive layer. Surface contamination can prevent the formation of the passive layer and cause stainless steel to corrode. Heat tint or weld burn discolouration are such surface contaminants and require removal.

Request for a quote

WORCESTER ENGINEERING

United Kingdom

We offer ZURICH certified Coded Welding Services as follows BS EN ISO 9606-1 : 2017 BS EN ISO 15614-1 : 2017 LEVEL 2 Our approval codings cover a wide range of applications within our target industries. We encourage enquiries for 'assembly & weld' opportunities. Our hygienic workshops offer a clean and efficient environment for multiple batch / jig work. We're happy to quote full job or just labour, free issue material. We have storage facilities and happy to discuss call off. We are happy to certify our workforce to any coding required to undertake customer requirements. Our coded welding staff are also placeable, providing cover for holidays, illness and staff shortages at your premises.

Results for

Welding - Import exportNumber of results

8 ProductsCountries

Company type