- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding

Results for

Welding - Import export

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing offers a range of welding solutions including MIG welding, TIG welding, robotic welding, projection welding and spot welding for aluminium, mild steel and stainless steels. Our highly trained weld team are some of the best in the industry and our quality is second to none. Robotic Welding Alpha Manufacturing's installation of a robotic welding has increased our capacity to offer high accuracy weld detail in volume as well as 100% product repeatability. Robotic Welding is the perfect solution for customers who require high volume, highly accurate, repeatable products. Alpha's robot welder boasts high-end features such as Cold Metal Transfer technology to eradicate spatter and reduce burn-through and distortion. The Robot also comes equipped with Seam Finding technology to ensure the robot always welds true to joining parts.

Request for a quote

SHEERSPEED SHELTERS LTD

United Kingdom

This speed tent is ideally designed for all your butt fusion and Electrofusion welding needs. Standard Specification: - Translucent Waterproof PVC, reinforced, flame retardant - top of side panels and roof section – allowing maximum amount of NATURAL light into work area - Heavy-duty Waterproof PVC material (500gms) coated on both sides – 3/4 height of side panel - 100% waterproof seams - Wet storage properties - Smooth wipe clean surface - Robust die cast central joints - Centre joint cover protection (INTEGRATED) non conductivity & finger protection - Fibreglass framework - Rubber protected feet for extended product life - Non-conductive - 3off guy straps & tent pegs - All spare parts available - No loose components – integrated frame and cover

Request for a quote

ERSEM MECHATRONIC LTD.

United Kingdom

We can manufacture metal parts as you designed. Or we can design for you.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

The water and gas pipe (DU) is produced from hot rolled sheet metal and is necessary for the installation of water and natural gas supply pipelines for residential and non residential buildings. Due to its low cost, the pipe is in demand in everyday life, mechanical engineering and at construction sites; metal products and steel structures , machine parts and other popular materials are produced from it . The vgp pipe is easy to install, its service life is from twenty to fifty years or more (time tested). In comparison with plastic counterparts, it is an excellent heat dissipating product and is more resistant to high temperatures and loads. Pipe DN GOST 3262 75 standard sizes from 15 to 50, wall 2.5 4 mm, length 6 lm. Longitudinal electric welded pipe is necessary for the production and construction of structural products, while the dimensional grid of longitudinal welded pipes differs in a larger direction from DU pipes F external 10 2000 mm; Wall up to 40 mm;

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

The water and gas pipe (DU) is produced from hot rolled sheet metal and is necessary for the installation of water and natural gas supply pipelines for residential and non residential buildings. Due to its low cost, the pipe is in demand in everyday life, mechanical engineering and at construction sites; metal products and steel structures , machine parts and other popular materials are produced from it . The vgp pipe is easy to install, its service life is from twenty to fifty years or more (time tested). In comparison with plastic counterparts, it is an excellent heat dissipating product and is more resistant to high temperatures and loads. Pipe DN GOST 3262 75 standard sizes from 15 to 50, wall 2.5 4 mm, length 6 lm. Longitudinal electric welded pipe is necessary for the production and construction of structural products. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Wire rod is an excellent consumable for the production and manufacture of knitting, spring, welding wire; electrodes for electric arc welding; hardware products; masonry and other mesh; ropes (cable) ; formwork manufacturing; concrete structures; metal structures . Wire rod can be either hot or cold rolled carbon steel. It is drawn on special drawing machines by drawing to a thickness of 5 to 15 mm onto special winding spools. The weight of one coil of wire rod is on average from 160 kg, depending on the initial diameter, order or consignment of goods. A circle of small diameters is made from rolled hot rolled wire by cutting; the product can also be supplied in bars. Quality The quality of the wire rod corresponds to GOST 30136 and is confirmed by certificates. Steel grade 3PS, 1PS, 2PS, 1KP, 2KP, 3KP, 1SP, 2SP, 3SP. Rolled wire is produced with the following strength classes B standard; B increased. You can contact us by mail - marketing@stalevar.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

2 and 3 axis tilt turn welding positioners for lifting, tilting and rotating the workpiece. The perfect automated solution for lifting, tilting and rotating workpieces of various capacities, shapes and sizes 360 degrees. Key Plant welding positioners are designed to significantly improve the productiveness of your welding and fabrication process. They increase quality and consistency of the weld, both by hand and automation. Their easy to use operation and accessibility with integrated equipment; also significantly enhances operator ergonomics. Available to buy and hire Comprehensive stocks Extensive capacity options Worldwide delivery

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

The ultimate cobot welding system available to buy and hire. ‘Ready to weld’ complete package The cobot welder includes all components being necessary for automated welding – perfectly matched to each other and easy to mount. The compact ” Ready to weld” cobot package is delivered completely ready for operation which ensures a problem-free integration into existing production processes. Exact, intuitive and safe A torque sensor in each axis allows the Cobotto be programmed and moved precisely. The intuitive operation significantly increases work efficiency. The user can make individual adjustments on the user-friendly touch control panel with macros specially developed for welding. In addition, the Freedrive option with foot switch and the intelligent safety concept guarantee sensitive and safe control of the cobot welder. Another special feature is the simple restart after an emergency stop as no extensive unlocking or free movement of the robot is necessary.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

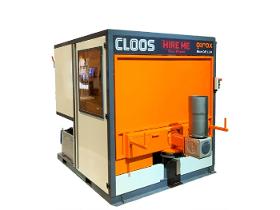

High performance plug and weld robotic welding cells. Cost effective, production boosting and floor saving, the pay by the hour robotic welding cells are delivered ready to weld, simply plug and go – it’s as easy as that! All cells are two station, Loading whilst welding, and are protected by a light barrier and safety fence. Hassle free delivery – straight to your facility and workshops. With their one lift, easy to transport modular design, the robotic welding cells are delivered direct, hassle free to your facility. Pay by the hour rental Ready to use, plug and weld Cloos welding technology One lift, easy to transport Save production floor area

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Enhance your automated welding processes for inner, outer, circumferential and longitudinal welding applications with Key Plant column and boom welding manipulators. Key Plant column and boom manipulators are developed to upgrade your fabrication throughput, and augment the quality of your weld production. We supply machines for a range of manufacturing environments; from pipe fabrication shops to tanker assembly lines, Key Plant provide the best solution to suit your project requirements. Key Plant have built a portfolio of global leading column and boom welding manipulators, available to buy, rent or lease. Our range consists of Mobile Pipe, Standard, Extra-Heavy and Telescopic models. But if your project demands are non-typical, our in-house capabilities and next-level engineering expertise enable us to develop special purpose machines for those more ‘complexed’ project needs.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Our heavy duty, built to last conventional welding rotators are designed and manufactured to tolerate the hardest, hard-wearing and unrelenting workload environments. The powered drive units are controlled by a five-function pendant with a variable speed potentiometer, giving the operator full control of the rotating workpiece. Available to buy and hire Comprehensive stocks Up to 500 tonne capacities Worldwide delivery

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TUSKER INDUSTRIAL SAFETY

United Kingdom

Tusker Industrial have produced an extensive range of welding safety gear including high-temperature fabrics designed to protect personnel, plant and equipment. Our industrial welding blankets and industrial fabrics provide solutions to the hazards associated with welding and fabrication and also dust protection, heat protection, sound insulation and chemical protection. Our high-tech materials and blankets can be manufactured to customer specifications, or are available in a comprehensive range of off-the-shelf options.OUR WELDING SAFETY SOLUTIONS Get in touch with our team if you require a solution for: Welding protection (including welding spatter protection, glare and spark protection) Heat retention and heat absorbing materials, thermal insulation and pipe insulation Grinding curtain Heat resistant material Heat reflective material Abrasion resistance Molten metal containment Temperature resistance Dust protection Sound insulation Acid and oil resistance

Request for a quote

TUSKER INDUSTRIAL SAFETY

United Kingdom

Tusker Series Elephant Frames, Manhole Tents and Welding Umbrellas- ready assembled, foldaway and mobile Available in a range of sizes with a selection of covers to suit, our elephant frames and shelters offer an excellent quality solution for protection from the elements and for both welding and non-welding applications.

Request for a quote

TUSKER INDUSTRIAL SAFETY

United Kingdom

If you’re looking for a welding bay system, welding booth, or a bay system for any other purpose, no matter how extensive, Tusker Industrial Safety can deliver. Our technical team will consult with you and design a welding booth to meet your exact requirements. With a wide range of curtain materials (including PVC strip curtains) and fixing systems available, our versatile, modular solutions will suit your application. We can provide all the necessary supplementary documentation including technical drawings, risk assessments and method statements. A dedicated project manager will keep you informed at every stage of the process.

Request for a quote

TUSKER INDUSTRIAL SAFETY

United Kingdom

At Tusker, we design and manufacture an extensive range of fire-retardant mobile welding screens, welding curtains, welding frames and welding tents, as well as a comprehensive range of industrial partitioning solutions and PVC strip curtains. For our customer’s flexibility, we can produce welding screens and tents in an array of different materials, including PVC and canvas. We pride ourselves on producing high-quality safety solutions and exclusively manufacture our products in the UK. The perfect safety solution for welding and manufacturing environments, our screens, tents and curtains can also be used for non-welding applications, such as x-ray shielding, dust booths and as radiation protection in medical environments or in scanning areas in airports. Our products can be used across a wide range of industries, including: Automotive Aviation Food Manufacturing Heavy Machinery Mining Railways Warehousing

Request for a quote

ANOPOL LTD.

United Kingdom

Stainless steel derives its corrosion resistant properties from a thin oxide film on the surface, often referred to as a passive layer. Surface contamination can prevent the formation of the passive layer and cause stainless steel to corrode. Heat tint or weld burn discolouration are such surface contaminants and require removal.

Request for a quote

SEEKO INTERNATIONAL

United Kingdom

Our RX 1 Helmet supplied with our F300T ADF & the FA100 Advanced PAPR. Please see individual product listings for product details.

Request for a quote

SEEKO INTERNATIONAL

United Kingdom

The FA100 is a TH3P S L rated PAPR unit as tested according to EN:12941. Designed with welders in mind, the FA100 offers high levels of protection, a robust & strong design whilst maintaining comfort levels not usually available. Alongside the standard waist belt, the FA100 also has a unique shoulder harness option to reduce stress on the lower back. Simple and clear status display Brush-less Motor for smooth and ultra quiet running Variable Airflow Speed Control offering 175L/Min or 225L/Min Removable Li/ion Battery Run time 10hrs+ Oversized controls for use with gloves metal spark arrester Light weight @ Less than 1.1kg

Request for a quote

SEEKO INTERNATIONAL

United Kingdom

Super Tough Lightweight Nylon Shell. Range of ADF's available, each offering an optical class of 1/1/1/2 or better. Tested and CE certified to EN 175B and ANSI Z87.1 Offers extended coverage of the ears & neck. Contoured flares to help channel fumes away. Pro head gear with 3 positional longitudinal adjustments & 5 angular positions Suitable for use with FA100 Advanced PAPR Unit Available with a safety helmet adapter. Fully customisable graphics available on request & subject to minimum order quantities.

Request for a quote

HADE SAFETY

United Kingdom

We produce high-quality TIG Welding Gloves according to the CE standards. All sizes of welding gloves are available as per customer's requirements (25cm, 35cm, and 40cm) and leather thickness is 1.1mm to 1.3mm. We use high-quality leather material to increase the overall safety of the worker in any extreme condition.

Request for a quote

WORCESTER ENGINEERING

United Kingdom

We offer ZURICH certified Coded Welding Services as follows BS EN ISO 9606-1 : 2017 BS EN ISO 15614-1 : 2017 LEVEL 2 Our approval codings cover a wide range of applications within our target industries. We encourage enquiries for 'assembly & weld' opportunities. Our hygienic workshops offer a clean and efficient environment for multiple batch / jig work. We're happy to quote full job or just labour, free issue material. We have storage facilities and happy to discuss call off. We are happy to certify our workforce to any coding required to undertake customer requirements. Our coded welding staff are also placeable, providing cover for holidays, illness and staff shortages at your premises.

Results for

Welding - Import exportNumber of results

28 ProductsCountries

Category

- Welding robots (5)

- Nuts and bolts, custom-made (5)

- Autogenous welding machines (3)

- Safety equipment, work (3)

- Welding, electric - equipment and supplies (2)

- Pipes and tubes, steel (2)

- Technical textiles for industrial applications (2)

- Welding, soldering and brazing - equipment and supplies (1)

- Industrial sheet metal work (1)

- SMALL METAL PARTS (1)

- Nuts and bolts (1)

- Cleaning and maintenance - equipment and supplies (1)

- Dairies - machinery and equipment (1)

- Fire-resistant clothing (1)