- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel

Results for

Stainless steel - Import export

STAINLESS BAND LTD

United Kingdom

Health and safety is of paramount importance to all industries. Our introduction of edge rounding and dressing eliminates the sharp edge, known as a burr that occurs during the production of steel strip and coil. Our updated edge dressing machines are capable of producing both large and small quantities of stainless steel strip and coil with a kinder safer rounded edge or full round edge. We can edge dress on site to a maximum width of 150mm. Certificates of conformity, showing the exact chemical composition of the material are supplied with each delivery. We provide: Bevelled Edge - Used for spiral wound gasket production, with 90º angles. Sak - Fully Rounded Edge - Many clients require material to have a fully rounded edge (SAK). GK - Slit edge Standard material with a maximum burr 5% of the material thickness. WAK - Flat rolled edge - Many clients require material to have a deburred edge (WAK).

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band’s in-house slitting line offers the capability for slitting up to 1250mm wide coil x 0.20 - 1.50mm thickness in 304/316L/321 and 430/409. Other grades are available on request. Also offering material as PE or PVC coated/with foil. Coil sizes range from 200kgs to 3500kgs depending on final widths. This unique line means Stainless Band can handle coils up to 8.5 tonnes on-site made from stainless steel AISI 304/316. This will reduce pricing and also improve delivery times to clients for wide coil and also standard products that Stainless Band provide. They offer good formability, corrosion resistance, toughness and good mechanical properties. As a result they are widely used for insulation and engineering applications. These grades are non-magnetic in the annealed condition. The density of our wide coil is 8.03kg/cm3-0.29 Ibs/in3. The modus of elasticity is 200 Gpa.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316.

Request for a quote

STAINLESS BAND LTD

United Kingdom

At Stainless Band we pride ourselves on supplying a wide range of steel strapping and boxed banding for delivery to the USA/Canada. Standard materials 0.015“ and 0.020“ thickness, other sizes can be produced to suit order requirements. Grade 304 and 316. Full Round Edges (100% safe edges). We can provide, boxed banding, oscillated banding, pancake coil and aluminium box banding as well as wing seals/closed seals in stainless steel and aluminium.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band work with high technology industries. Our slitting and shearing services are available at 0.10mm - 3mm thickness and from 2.50mm wide. We can cut to length from 100mm long to 4000mm long. We provide a comprehensive temper rolling and edge dressing service including deburring round edge and straightening. We have in-house bobbin winding facilities on plastic bobbins or large wooden spools and can apply protective coatings to product if required. As will all Stainless Band products in-house testing takes place and material test certificates are supplied with every delivery. You are in safe hands with Stainless Band.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316

Request for a quote

STAINLESS BAND LTD

United Kingdom

At Stainless Band we have the capacity to polish material in coil form or blanks in various grades including AISI 304-S15- 1.4301 EN 10088-2/ASTM A240. We can offer the following finishes from 120 to 320 Grit as well as standard 2B or BA finished. Material can be made into blanks with lengths from 100mm to 3000mm long. Standard thicknesses 0.10ms from m - 4.00. and widths from 2.50mm to 1500mm maximum. Our standard tolerance is EN ISO 9445:2006 but others are available. We can provide coating films, PE and PVC surface protection. Finishes can range from smooth and slightly reflective through course, medium, fine and bright and reflective.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Rolled stainless steel is intended for the production of visible and durable buildings, parts and goods. Stainless steel is especially popular in everyday life, construction, mechanical engineering and medicine. Rolled stainless steel has the form Matte; Polished; Mirror. Depending on the requirements and place for the installation of stainless steel, a selection of its type is made. Stainless steel is resistant to aggressive environments and, if used correctly, is a durable material, because it is no secret that products made of this metal, just like gold, are passed from generation to generation. According to the method of appointment, stainless steel can be used both for food, for example, steel 08X18H10, and for non food products. Stainless steel is produced at factories in our country (according to GOST) and abroad (according to DIN). Stainless steel sheet DIN EN 10088 2 (strip) is intended for the production of children's playgrounds

Request for a quote

A2Z FASTENERS

United Kingdom

All types of nuts, bolts, washers, set screw and many more types of fasteners available in different material and sizes. Materials include stainless steel, bright zinc plated, brass , galvanized, steel and aluminum. We also have a huge size range starting from 1mm to 50mm in thread diameter also large range in length.

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

ASMS659 is a heat and corrosion resistant steel. We hold this grade in round bar form. The material is typically used for parts requiring good corrosion resistance which will be subjected to elevated temperatures during fabrication and service. The material is particularly good for parts requiring oxidation resistance up to 816oC. Material is supplied in the solution heat treated condition.

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

Alloy 17-4 PH is a chromium-copper precipitation hardening martensitic stainless steel with Cu and Nb/Cb additions. 17-4PH Stainless Steel combines high strength, hardness (up to 572°F / 300°C), and moderate corrosion resistance. Alloy 17-4 PH withstands corrosive attacks better than any of the standard hardenable stainless steels and is comparable to Alloy 304 in most media. The alloy is subject to crevice or pitting attack if exposed to stagnant seawater for any length of time, although it is corrosion resistant in some chemical, petroleum, paper, dairy and food processing industries(equivalent to 304L grade). Mechanical properties can be improved (high strength and superior corrosion resistance) when precipitation hardened from Condition A to one of the Condition H tempers. We supply 17-4 PH in the H1150D condition. This is double aged at a temperature between 1140° F and 1160° F for 3.75 hours to 4.

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

Base material for cold drawing is ASTM A276. UNS S32760 F55 solution annealed material that complies with Condition A. After cold drawing (strain hardening) material meets ASTM A276, UNS 32760 F55 Condition S. Material that meets required impact test requirements will be further designated as variant 'FG', 'FLT', or 'FLT+'

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

13-8 Mo VIM-VAR steel is a precipitation hardening martensitic stainless steel/ It offers excellent strength, fracture toughness and transverse mechanical properties. The material is resistant to stress, corrosion cracking and has the high strength characteristics common to the family of precipitation hardening steels. The alloy is double vacuum remelted (VIM-VAR) which assures low gas content, improved homogeneity and superior cleanliness

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

ASMS659 is a corrosion resistant steel. We hold this grade in round bar form in both the solution treated condition (Condition A) and in the H1025 precipitation treated (aged) condition. The material is typically used for part s requiring corrosion resistance and high strength up to 300oC. The material exhibits good ductility and strength in the transverse direction in large section sizes SIZES STOCKED: Condition A – 9.5 mm dia – 152.4 mm dia H1025 condition – 12.7 mm dia – 152.4 mm dia

Request for a quote

ANOPOL LTD.

United Kingdom

A clean stainless steel surface will generate its own passive oxide layer when exposed to oxygen. It is this oxide layer that gives stainless steels their corrosion resistant qualities, it is possible however to accelerate the formation of this layer by chemical passivation.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We hold a complete range of stainless steel handrail tube in all standard diameters. By maintaining strong relationships with our suppliers, we can source additional components or fittings upon request. These components allow for quick installation of even the most complex and attractive stainless steel railings and balustrade systems. >Material is available in both grades 304 (1.4301) and 316 (1.4401), and comes either in un-polished, satin polished or mirror polished finish.

Request for a quote

DSM INDUSTRIAL ENGINEERING

United Kingdom

DSM can create almost Stainless Steel Bar Sinks to almost any specification. this means that you can be sure that you're getting a product that fits your space perfectly! We even give a 25-year guarantee with each and every product that we create.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAINLESS WIRE SUPPLIES LTD

United Kingdom

Stainless Steel Bright Wire, Annealed Wire, Cold Heading Wire, Spring Wire, Wire for Braiding, Wire for Weaving, & Welding Wire

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

A complete turnkey service for all Technical Brushes & Seals from concept through to delivery and after-sales. Please contact us for information.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Our aluminium boxed banding is available from stock in widths from 12.70mm (1/2”) to 25.00mm (1”) wide and thickness 0.30mm (0.012”) to 0.50mm (0.020”) Standard grade 1050 HH other grades are available at request. Coils can be supplied as standard 2kg rolls or as boxed banding with safe edges. Supplied on wooden pallets and shrink-wrapped. Maximum pallet weight 1500kg. A full export service is available for worldwide supply. Aluminium wing seals in 12.70mm (1/2”), 19.05mm (3/4”) and 25.00mm (1”) sizes are also available, and are compatible with aluminium or stainless steel banding. Certificates of conformity, showing the exact chemical composition of the material are supplied with each delivery.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Customers who use narrow width strip can increase productivity with oscillated wound coils as large as 1000kgs. The benefit of this larger wound coil is that the coil needs to be changed less frequently and therefore reduces downtime. Common uses for oscillated wound is the building industry and automotive sector, this process has been proven to increase machine output by 40% on pressing lines. Our oscillating wound is available in thicknesses 0.40-3.00mm with a width to 3.00-80mm. With a coil weight of 100kgs or coil OD 1,000,00mm and pack width optional 200/350mm. Our stainless steel oscillating wound is WAK edge dressed on wooden spools. The inside diameter is 406, 508 flash butt welding method with reannealing. The welding method is 90 degree TIG-skew tolling, seam smoothened. Marking is in accordance to client specification.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Hot rolled angle is in demand and applicable in mechanical engineering, construction and in everyday life. It is used to make Concrete supports; Mounts; Brackets; Arches; Ladders, stepladders; Wall partitions; Armored doors; Fences and fences; Sports equipment and exercise equipment; Children's playgrounds (playgrounds); Lifting equipment; Steel structures ; Parts and assemblies (mechanical engineering). By the type of execution, it is rolled with equal edges (equal flanges) GOST 8509, with different edges (unequal flanges ) GOST 8510 and bent. An equal flange metal corner is rolled at Ukrainian factories of the established length 6 and 12 meters, the geometry of the shelf is from 25 to 300 mm, the thickness of the edge is from 3 mm or more. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

BETA VALVE SYSTEMS LTD

United Kingdom

Our Stainless Steel valves from ACL are employed in a large variety of industrial sectors: water treatment, electrical appliances, industrial process, heating and air-conditioning, medical equipment, automotive, textile, food, pneumatic and many more.....

Request for a quote

JC CATERING & BAR SUPPLIES LTD

United Kingdom

Our stainless steel gastronorms are stackable and can be hidden away to save space, making them very practical and ideal for using in restaurants, hotels, and buffet serving situations.

Request for a quote

ANOPOL LTD.

United Kingdom

Stainless steel derives its corrosion resistant properties from a thin oxide film on the surface, often referred to as a passive layer. Surface contamination can prevent the formation of the passive layer and cause stainless steel to corrode. Heat tint or weld burn discolouration are such surface contaminants and require removal.

Request for a quote

ANOPOL LTD.

United Kingdom

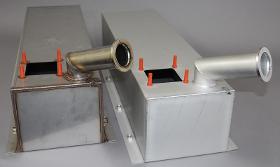

Anopol can design, build and install plant and equipment for customers to carry out their own electropolishing, pickling & passivation.

Request for a quote

ANOPOL LTD.

United Kingdom

Anopol offer comprehensive in-house and on-site subcontract services for cleaning, pickling, passivating and electropolishing of Stainless Steel with projects having been carried out by our site teams in the UK and throughout the world.

Request for a quote

ANOPOL LTD.

United Kingdom

The ANOPOL range of products for Cleaning, Pickling and Passivating stainless steels removes contamination, improves corrosion resistance and can produce a clean, aesthetically attractive appearance. In addition ANOPOL offers 2 types of Test Kits, one for checking the presence of free iron on a surface and the other for differentiating between grades 304 and 316.

Request for a quote

ANOPOL LTD.

United Kingdom

Electropolishing is in effect electroplating in reverse. Instead of depositing a coating of another material on a surface the process of electropolishing is to remove a surface layer, typically 20-40 micro-metres in depth in the case of stainless steel.

Request for a quoteResults for

Stainless steel - Import exportNumber of results

38 ProductsCountries

Company type