- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ultra clean

Results for

Ultra clean - Import export

SARL REFICO

France

BLAUPUNKT 3-piece set: 2 saucepans 6.3''/7.87'' - 1 removable handle inside non-stick coating (stone effect) PFOA-free, Exterior: shiny nox stainless steel - Internal graduations for shiny stainless steel saucepans for easy cleaning. Ultra-thick diffuser capsule base 3 layers All heat sources including induction + oven dishwasher safe. Present box. 5 years warranty.

Request for a quote

SARL REFICO

France

BLAUPUNKT - Set of 3 frying pans 9.45''/10.24''/11.02'' non-stick coating (stone effect) PFOA-free, Exterior: shiny stainless steel For easy cleaning. Ultra-thick 3-layer diffuser capped bottom. 3-point riveted handles Stainless steel for all heat sources including induction + oven. Dishwasher safe. Present box. 5 years warranty.

Request for a quote

SARL REFICO

France

BLAUPUNKT 3-piece set: 2 frying pans 9.45''/11.02'' - 1 removable handle inside non-stick coating (stone effect) PFOA-free, Exterior: shiny nox stainless steel - Internal graduations for shiny stainless steel pans for easy cleaning. Ultra-thick diffuser capsule base 3 layers All heat sources including induction + oven dishwasher safe. Present box. 5 years warranty.

Request for a quote

ROBINSON CO.

Turkey

Flowing the dry cleaning of wheat, it is used for the humidity of wheat with a little consumption of water and time. At the same time, the wheat is unshelled also because of the two rotor, which turns with high speed.It can add up to 7% of water in a single flow-through.

Request for a quote

ID GROUP

France

draining thanks to its pinned backing antislip flexible easy to clean ultra sturdy selfweighted reassuring soundproofing thermal insulation soundproofing

Request for a quote

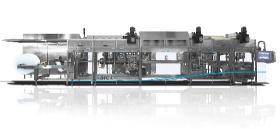

SYNERLINK

France

Our DN250 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed of 18,700 to 43,200 cups per hour. Our machine can handle various materials (PS, PET, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

SYNERLINK

France

Our AR700 cup thermoforming machine is known for its user friendliness, great reliability, simple design and layout. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Its high adaptability to changing market needs and easy operation and maintenance are ideal for high speed production lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 57,600 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical, straight and open mold cups with or without label.

Request for a quote

SYNERLINK

France

Our DP300 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. This machine versatility and technical efficiency are ideal for medium lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 28,800 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® CORUS HD ultrasonic systems have been specially designed for cleaning high-quality moulds and precision tools. In maintenance these replace the labour-intensive and often ineffective manual cleaning. The ultrasonic cleaning process can be used for all metal moulds, in particular tools for injection moulding, extrusion, rubber processing as well as aluminium and gravity die casting. A typical structure consists of three stages: 1. cleaning, 2. rinsing and 3. passivating. The usable dimensions are matched to common mould sizes. The workpieces to be washed are placed in the tank either with the aid of a washing basket or with a lifting beam. Our ErgoStation is recommended for manual rinsing, drying and post-treatment. The working area is completely enclosed, brightly illuminated and ventilated. Operation is safe and simple, as the moulded parts are loaded laterally through a sliding door and held by a lifting device during treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® VERSA GENIUS+ ultrasonic cleaning system enables individual, demand-oriented mould and parts cleaning. The modular design allows adaptation to almost all process requirements. Later expansion or automation is possible at any time. WIWOX® VERSA GENIUS+ ultrasonic cleaning systems consist of washing, jet, rinsing and drying modules as well as the corresponding accessories. The spectrum ranges from individually operated cleaning basins to fully automated, multi-stage cleaning lines. WIWOX® VERSA GENIUS+ sets new standards in modern plant design. Well thought-out details in the area of guiding the cleaning medium, agitation and process control ensure a flexible and energy-efficient process sequence that meets the requirements. You can convince yourself of the economic efficiency of the system by extensive cleaning tests in our test laboratory. The bath care accessories also play an important role in the cleaning result, the uniform process flow and the operating costs.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® USm Ultrasonic cleaning tanks enable individual, demand-oriented surface treatment in a single or multi-stage process. The modular design allows adaptation to almost all requirements and subsequent expansion or automation is possible at any time. Aqueous cleaning at temperatures between 60° and 80° C ensures absolute degreasing and particle removal. Organic or inorganic residues such as polishing paste, paint, plastic, release agents, oil carbon or lime can be easily removed by using the right cleaner. The workpieces are cleaned within a few minutes. The cleaning result is always perfect and reproducible. The subsequent rinsing process is followed by stain-free post-cleaning or preservation. The WIWOX® ultrasonic cleaning process can be used for all steel moulds as well as brass and copper parts. Especially tools for injection moulding, extrusion, rubber processing, aluminium die casting and gravity die casting.

Request for a quote

WEBER ULTRASONICS AG

Germany

The Sonosub Multi submersible transducer produces ultrasound with three different frequencies and masters a wide range of cleaning tasks: From course to ultra-fine cleaning of a work pieces or cleaning of different work pieces with individual cleanliness requirements.

Request for a quote

WEBER ULTRASONICS AG

Germany

With its two frequencies, the Sonosub Dual shines for course cleaning as well as fine and ultra-fine cleaning tasks. Equally convincing: The dual-frequency resonating elements and the seamless laser-welded body.

Request for a quote

WEBER ULTRASONICS AG

Germany

The plate transducer Sonoplate Multi grants the highest degree of flexibility. Its three frequencies allow for a 3-stage cleaning process from course, fine to ultra-fine or for the cleaning of different work pieces.

Request for a quote

ZEPTER INTERNATIONAL

Switzerland

The Santoku Knife is best known for its extra sharp edges and wears its name proudly with a marvelous ability for chopping, cutting, dicing and mincing. Very popular with budding chefs and master chefs, the 19cm, (7.5-inch) knife is made from top quality x46Cr13 blade-steel. Thanks to the 19 air vents and the wiper rail, absolutely nothing sticks to the hand-ground blade while cutting. Presentation SANTOKU TURNS COOKING INTO ART! Similar to a narrow-bladed cleaver, the Santoku knife is designed for a comfortable, well-balanced grip, while allowing for full blade use. The quality, function and design of this Santoku knife is unique. The handle, made of polyoxymethylene, is strong, practical and easy to clean. FELIX® ZEPTER®: CUTTING EDGE QUALITY & TRADITION From blade and handle sandblasting to straightening, edge polishing, etching and ultra-sonic cleaning, handcrafting the world’s best carving knife requires a dedication to quality and tradition.

Request for a quote

DEL' LA SOFT

Turkey

GENTLE ON SKIN – Ultra soft and thick to clean and refresh better than dry toilet paper alone. HYPOALLERGENIC – Alcohol-free and contain aloe and vitamin E 100% PLANT BASED – Free of chemical binders FLUSHABLE WIPES – Safe for well-maintained sewers and septics. Only flush one at a time. BONUS MOIST TOWELETTES – Includes exclusive bones moist towelettes to take on the go!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

Novafix Ultra Plate Cleaner is desi gned as a troubleshooting product, especiall y suitabl e far use on baked positive ptates with UV and hybrid inks. Novafix Ul tra Plate Cl eaner coupl es the powerfut cleaning action of the novafix plate cleaner with a fine suspension of abrasive to produce an emulsion cteaner that witl removedried ink and oxidation with ease whilst having a minimal effect on the image areas. PROPERTIES Eff ective cleaning Cost effective Suitabte far removing dried ink from stored plates and heavy duty applications. Water soluble Especially UV and hybri d inks APPLICATION Apply it manually to the blanket surf ace. After cleaning plate surface, rinse it with water. * The information on this technical data sheet is based on our general experience. The tests are carried out under controlled laboratory conditions. The information may change as conditions change. The performance of the product and the suitability of the print made depends on the printing conditions

Request for a quote

DE WITTE SA

Belgium

Knitted cloth Excellent cleaning qualities Absorbent Ultra-soft Suited for all applications: car cleaning, furniture, desks, hotel rooms, kitchen, …

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Is a self-contained filtration and fluid recovery system. The fully automated unit minimises fluid loss during cleaning and is ideal for 24/7 high volume single or multi-cell machining applications providing: Unique Dual Flow Technology ™ – maximising collection capability No user intervention required Suitable for harsh chemical environments PLC compatible Ultra-fast automated cleaning No reduction in pressure or flow Rapid return on investment Built in fluid recovery system Flow rates of up to 1800 litres per minute Double Automag Skid units are available for large flow rate/heavy contamination applications. Contact us for further information.

Request for a quote

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 8000 capping machines are specifically engineered for aseptic filling and ultra clean applications. These cappers incorporate full stainless steel construction and the most advanced corrosion-resistant materials. The open design facilitates cleaning and rinsing to optimize hygiene levels. Series 8000 machines are fully metric, perfect for global use and are suitable for plastic and aluminum caps. High Performance Features for "Aseptic" Capping Full stainless steel construction to prevent corrosion Open design for ease of cleaning and 100% rinsing Pick station drive unit designed with sloping surfaces and lubricant-free hybrid bearings to maintain cleanliness Pick station provides precision closure delivery with minimal contact points to improve hygiene Lubrication free spindles utilizing state of the art materials and design technologies to provide extended and predictable maintenance intervals of 4,500 hours Headsets specifically developed...

ZS-HANDLING TECHNOLOGIES GMBH

Germany

The LeviSolar-Gripper enables contactless gripping and depositing of solar wafers. Our technology guarantees the ultragentle and ultra-clean handling of the sensitive surfaces. When gripping the wafer, a combination of vacuum and ultrasound is used. The vacuum provides the attraction of the wafer and the ultrasound keeps the workpiece, with its repelling effect, at distance. Thus, no points of contact occur between the wafer and the gripper, and gentle handling is ensured. The LeviSolar-Gripper is available for different wafer sizes. The edge stops support the wafer to center itself and to stay in position. Features of the LeviSolar-Gripper: - Contactless overhead lifting - No carry-over of impurities and no micro scratches - No need for compressed air

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tretra 320R low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 320 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Atto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 10.5 litres of this plasma system offers enough space to serve laboratory and also small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 30 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 34 up to 50 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Pico low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 5 up to 8 litres of this plasma system offers enough space to serve laboratory and also series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Nano low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 18 up to 24 litres of this plasma system offers enough space to serve laboratory and also series production. Plasma treatment in low-pressure plasma is a proven technique for controlled ultra-fine cleaning, improvement of adhesion (activation and etching) and coating of thin layers on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues. Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 45 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 45 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Zepto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1 - 4 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quoteResults for

Ultra clean - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Surface treatment - machinery and equipment (12)

- Food Industry - Machines & Equipment (4)

- Houseware, steel (3)

- Sandblasting equipment (3)

- Cleaning and maintenance - equipment and supplies (1)

- Cleaning and maintenance products, household (1)

- Flour milling - machinery and equipment (1)

- Food packaging (1)

- Internal transport systems (1)

- Perfumes - essences and scents (1)

- Screen filters (1)

- Sheets, rubber (1)

- Tableware (1)

- Tile and tile floors, porcelain (1)

- Varnishes (1)