- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spraying system

Results for

Spraying system - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

In the spraying pre-treatment method, applying chemicals with a certain pressure on the parts creates big positive differences on paint quality and life span. By cleaning and coating the surface of the part before painting, the paint will retain its first-day quality with out any degradation for long years by strong adhesive forces. Our spray tunnels, with the help of automation systems, allow you to be able to produce automatically and continuously with out any touch. Tunnel type spray surface cleaning lines consist of parts like spray nozzles, heat exchangers, dosing pumps and ventilating systems. In our spray lines, the AISI 304 – AISI 316 stainless sheets of steel and polypropylene are used. According to needs of our esteemed customers, horizontal belt type conveyor, compact type, and rotary table type automatic plc controlled washing machines can be produced by us. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation

Request for a quote

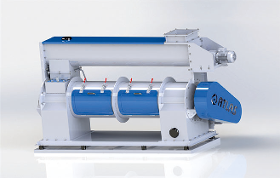

PARSMEGA MAKINA

Turkey

It ensures the production of the product with the desired properties by providing the appropriate additive for the appropriate feed. It provides continuous and homogeneous mixture with the liquid spray system and can be easily cleaned thanks to its wide covers.

Request for a quote

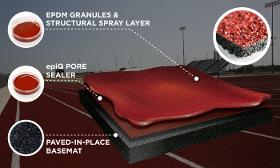

BS ATHLETICS

Turkey

At its core, a spray coating system is a method of applying a protective or decorative coating to a surface using specialized equipment that atomizes the coating material into tiny droplets and sprays it evenly across the target area. This process ensures uniform coverage and adherence, resulting in a seamless and durable finish. Key Features and Advantages: Precision Application: Spray coating systems allow for precise control over the application process. The fine mist of coating material can be directed accurately to cover even complex and irregularly shaped surfaces, leaving no gaps or streaks. Efficiency: The efficiency of spray coating systems cannot be overstated. They can cover large areas quickly, reducing application time and labor costs. This efficiency is especially valuable in industrial settings where time is of the essence.

Request for a quote

EMS MACHINERY SYSTEMS CO.LTD.

Turkey

EMS Makina Manufacturing in Turkey Top Loading Waste Transfer Stations. Steel conveyor waste transfer station is used for unloading the solid municipal wastes, that were collected from the inner-cities with smaller garbage trucks, in to bigger capacity waste transfer semi trailers so that the municipal solid wastes can be transported to the landfills economically. TOP LOADING WASTE TRANSFER STATION: CAN BE DEMOUNTED AND TRANSFERRED EASILY. HAS SPRAYING SYSTEM AGAINST BUGS AND FOUL SMELL, CHAIN TYPE, ELECTRIC ENGINE OR IF ELECTRICITY NOT AVAILABLE AIR OR WATER COOLED DIESEL DEUTZ ENGINE. 5 TON/H -90 TON/H SINGLE UNLOADING FACILITIES , 10 TON/H- 180 TON/H HIGH CAPACITY FACILITIES. For more information please contact with us. We would kindly like to help!

Request for a quote

ONURAY

Turkey

HT BEAM and ROTARY HT BEAM Fabric Dyeing Machines are a NEW TECHNOLOGY developed by ONURAY and allow flawless dyeing of all kinds of fabrics at low cost. It can be produced in different widths and capacities. (100,200,400,800 kg) Low liquor ratio ( 1/3 – 1/4 ) Internal washing and spraying system. Safe cover system. Flap system that allows bidirectional (exterior-interior / interior-exterior) operation. PLC Programmed dosing and mixer. Rapid Discharge Electronic speed-controlled pump. Fully automatic PLC controlled working program.

Request for a quote

ONURAY

Turkey

ECO-DYE HT Jet Fabric Dyeing Machines are specially designed to dye cotton, viscose or blends sensitive to friction in the best way possible. It can be produced in high and variable capacities. It can be produced in high and variable capacities. (300 kg- double cabin in single body) Low liquor ratio (1/4 – 1/6) High fabric cycle speed (500 m / min) Internal washing and spraying system. Safe cover system. Variable nozzles Wide surface filter. Teflon Coated J-Boxes. Dosing and mixer with PLC program. Rapid discharge Electronic speed-controlled pump. Fully automatic PLC controlled working program.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

It is an easily adjustable and useful machine. Work efficiency is high. Our warehouses are produced from polyester against the harmful effects of pesticides. The turbo fan is produced from Chrome (Cr)-Nickel (Ni) or galvanized sheet metal against corrosion. Angle-adjustable domestic propeller or high air flow Italian propeller is used. The water filter can be cleaned easily. It has a hydraulic mixing system. Thanks to the regulator, the pressure can be adjusted according to demand. In this way, spraying can be done at the desired flow rate. It can be easily connected to the tractor with a three-point suspension system. The turbo atomizer nozzle can rotate around its own axis to adjust the spray distance.There is a separator system in the propeller. There is an embossed and transparent level indicator on the tank.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION DC 421 MS is designed for the strait or angular cutting operations of large size of profiles made of aluminum and PVC materials by means of double head sawing units equipped with Ø 420 mm of saw blades. Two-hand run safety operation Manual adjustment of intermediate tilting angles from 90° to 45° inwards Hydro-pneumatic saw blade feed Cutting accuracy +/- 0.2 mm Manual positioning of cutting units Solid steel construction of the body Conveyor & 2 x pneumatic profile supports Automatically closing safety guards Horizontal pneumatic material clamps to ensure optimum material fixing STANDARD ACCESSORIES • Equiped with Ø 420 mm of saw blades • Roller conveyor & 2 x manual profile supports • 4 x horizontal clamps • Air gun • Spray saw blade lubrication system OPTIONAL ACCESSORIES • Profile Length Stop for cutting short pieces (DKN 70 with digital unit, DKN 71 with ruler) • Machine with the length of 5m and 6m • VCE 1570 Chip vacuum extractor

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on aluminum profiles up to 3 mm of thickness. Copy fitting operates manually and the figures on the template are machined at 1:1 ratio The aluminum profiles up to 3 mm of wall thickness can be machined with a strong spindle motor The cutting fluid controlled with a joystick is sprayed to the milling spot Slots in varied lengths and widths can be opened without using the copy milling template The length of the water drain slot is adjustable on the template Copy milling motor is directly controlled via joystick Reference stops at 2 sides of the milling machine Standard equipped with inlet-outlet conveyor Ergonomic hand control unit STANDARD ACCESSORIES • Ø 5mmx L :80mm of router bit • Air gun • 2 x profile stops both left and right • Spray tool lubrication system • 2x horizontal clamps OPTIONAL ACCESSORIES • Additional router bits

Request for a quote

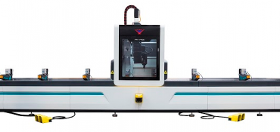

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4420 is a 4-axis servo-controlled machining center that is designed to perform drilling, grooving, notching, taping, sawmilling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin-walled steel profiles. Efficient and economic processing on the three sides of the profiles is possible with this fully automatic machining center. General Features: • It is designed to make operations on three surfaces of the profiles such as a hole, slot, corner relieve, saw cutting, tapping, flow drilling, etc. • CNC automation system providing motion control at 4-axis • Linear type of magazine unit for 11 standard tools and Ø180 mm of the saw blade • Flow drilling and tapping feature by means of encoder spindle (optional) • Automatic clamp recognition and clamp positioning are available • CNC controlled spray tool lubrication system • Pneumatically working 4 pcs of clamps for gripping the workpiece

Request for a quote

YILMAZ MACHINE

Turkey

VK 420 is designed for the precise V cutting and 90° end notching operations with minimal off cut size on aluminum and PVC profiles. Machine is constructed to minimize the off cut size Hydro-pneumatic V sawing head infinitely adjustable according to the profile Manual adjustable of back fence working in T slot mechanism Double hand safety operation External adjustment of hydro-pneumatic saw blade feeding 90 degree of notching operation (optional) STANDARD ACCESSORIES • 2 x T.C.T saw blades, Ø 420 mm • 2 x Horizontal pneumatic clamps • Service spanner • Air gun • Spray saw blade lubrication system

Request for a quote

YILMAZ MACHINE

Turkey

SK 450 is designed for the strait cutting operations of the large size of profiles made of PVC and aluminum by means of Ø450 mm of saw blade at 90°. It is ideal for the serial and precise slicing operations. Suitable for high-volume slicing of aluminum profiles for window manu facturing and industrial applications High precision servo motors and inter nationally recognized components Saving of time by means of servo con trolled workpiece infeed speed and saw blade stroke Horizontal and vertical clamping of the workpiece during the sawing operation Automatic table retraction feature that moves the cut material a small amount after cutting and before the blade came back down to prevent the re-cut & scratches High cutting accuracy by means of the robust mechanical structure Programmable spray saw blade lubrication system via control panel Large memory capacity for the cutting programs The machine shut down automatically after reaching the requested quantity

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on PVC and aluminum profiles up to 3 mm of thickness. Opening locks, drilling handles, hinges, espagnolette holes etc. on PVC and aluminum profiles Cast aluminum structure Corrosion proof bearing shaft Robust machine stand constructed from steel sheet Electroplated copy template Two pcs of tracer pins Ø5 router bit included Clamping capacity : W max.:130, W min.:10, H max:130, H min.: 20 mm STANDARD ACCESSORIES • Ø5 mm of router bit • Air gun • 2x left and right profile stops • 2x pneumatic horizontal clamps • Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits • Special copy templates • MA 240 centering apparatus • MKN 150 roller conveyor TECHNICAL SPECIFICATIONS 750W 400V 50~60 Hz / 550W 230V 50 Hz x:270 y:110 z:130 mm 14000 D/dak. RPM W:64 L:80 H:149 cm. 110kg. 72 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is designed to operate quickly and precisely lock’s holes on aluminum and PVC profile, without releasing the workpiece. Copy router with 1 vertical and 2 horizontal spindle motors ( 3 x 1.1 Kw 12.000RPM) Designed to perform quickly and precisely lock’s holes on 3 sides of the aluminum profile without releasing the workpiece Pneumatic 2 x horizontal and 2x vertical clamps Horizontal and vertical pneumatic tracers with 3 diameters Ø 5, Ø 8, Ø 10 mm Horizontal & vertical templates with standard figures for Aluminum and PVC profiles Smooth movement, high precision and great sensitivity provided with gas spring and ergonomic handles 1 m of roller support table at the right (with ruller) and left side Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits with Ø5mm, Ø8mm and Ø 10mm • Additional collets with, Ø 8 and Ø10 • Special templates Videolar TECHNICAL SPECIFICATIONS 3x1.1 kw 1 P 230 V 50-60 Hz 6-8 Bar 8 lt./ min.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 700 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 700 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard Safety locking switches on top guard and front doors Double acting clamps for operator safety STANDARD ACCESSORIES • Equipped with saw blade Ø 700 mm& 4 Kw motor • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 2 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 700 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • Laser marker set for 90 ° of cutting operation TECHNICAL SPECIFICATIONS 4kW - 3P 400 V 50~60 Hz

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 550 is designed for the strait or angular cutting operations of the large size of profiles made of aluminum materials by means of Ø 550 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable saw blade feeding speed Interior LED lighting Pneumatically opening safety guard STANDARD ACCESSORIES • Equipped with saw blade Ø 550 mm • Spray saw blade lubrication system • MKN 301 roller conveyor (3 m) • 2 x vertical and 1 x horizontal clamps • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 550 mm • VCE 1570 Chip vacuum extractor • SKN 300-450-600 conveyor • DKN 302-452-602 conveyor • 1 x horizontal clamps • Laser marker set for 90 ° of cutting operation Videolar TECHNICAL SPECIFICATIONS 4kW - 3P 50~60 Hz 400 V 2400 D/Dak. RPM D: 550 mm d:30 mm 6~8 Bar 160 Lt/dak. 106x131x156 cm 419 kg 373 kg

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION ACK 420 S is designed for the strait or angular cutting operations of the large size of profiles made of aluminum and PVC materials by means of Ø 420 mm of saw blade. Two-hand run safety operation Location points at 75°,60°,45°,30°,22.5°,15°,0° both left and right Pivoting range from -75° left to +75° right infinitely adjustable Hydro-pneumatic saw feed Adjustable back fence for most effective use of the saw blade Adjustable saw blade feeding speed Manually opening safety guard Interior LED lighting STANDARD ACCESSORIES • Equipped with saw blade Ø 420 mm • MKN 301 roller conveyor (3 m) • 2 x vertical clamps • Spray saw blade lubrication system (ACK 420S) • Air gun OPTIONAL ACCESSORIES • Additional saw blade Ø 420 mm • 2x horizontal clamp • VCE 1570 Chip vacuum extractor • DKN 300-450-600 conveyor • SKN 300-450-600 conveyor • Laser marker set for 90 ° of cutting operation • Pneumatically working top guard Videolar TECHNICAL SPECIFICATIONS 2.2kW 50/60Hz

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DORU MAKINA VE DIS TICARET

Turkey

Multi-color Intelligent Yarn Dyeing Systems Fancy Master, which has an ergonomic and easy to use construction, is designed to work efficiently with its structure that allows maximum 60 wire thread passes with plc controlled movable arm in desired report size lengths It provides the opportunity to create a soiling pattern and ground pattern color on the yarn and to get different effects on the yarn. It is designed for high efficiency operation with special software and panel design that enables the super nozzle sets to open multiple times within seconds with special electromechanical valves. The system, which is integrated with a 400-rpm rotary spray system with 16 nozzles, 1 to 16 nozzles that can be operated individually, has been specially designed to achieve the desired dot effects on the yarn. There is an automatic controlled cooling system in the dye tank and a mixer to ensure a homogeneous mixture.

Request for a quote

AGROPA LTD.

Turkey

Strengthened fiber or polyethylene tank Clean water tank Fast filling system Choke preventive, effective spraying filtration system 5 vane angle turbo fan blower Pressure regulator control handle Hydraulic agitator system High spraying provider fully galvanized fan Bidirectional nodrip nozzles with ceramic plaque 2 speed transmission 2 step regulate axle 80'turning provider wide angle shaft that is secured by a plastic cover

Request for a quote

DENMAK MAKINA LTD STI

Turkey

BPM-700 concrete spraying machines and systems designed by DENMAK MAKINA are a must-have in your equipment pool due to their low price and low processing cost and ease of use. Due to its rotor structure, it is possible to use any commonly shotcrete material. By its advanced rotor geometry, hardened steel plates and special composite rubber plates it has less air and electricity consumption on operation than its competitors. Its specific oiling system lengthens the life of rubber discs by reducing mechanical wears and optimizes the operating costs. Double sealed water and dust resistant electrical panel provides safety to the operator, which is very crucial at worksite environments. Due to the ease of spare part replacement,it doesn’t require any qualified personnel or doesn’t need any calibration or adjustment to be done afterwards. It can be used in low ceilinged and narrow spaces because of compact design.

Request for a quote

DENMAK MAKINA LTD STI

Turkey

BPM-750 concrete spraying machines and systems designed by DENMAK MAKINA are a must-have in your equipment pool due to their low price and low processing cost and ease of use. Due to its rotor structure, it is possible to use any commonly shotcrete material. By its advanced rotor geometry, hardened steel plates and special composite rubber plates it has less air and electricity consumption on operation than its competitors. Its specific oiling system lengthens the life of rubber discs by reducing mechanical wears and optimizes the operating costs. Double sealed water and dust resistant electrical panel provides safety to the operator, which is very crucial at worksite environments. Due to the ease of spare part replacement,it doesn’t require any qualified personnel or doesn’t need any calibration or adjustment to be done afterwards. It can be used in low ceilinged and narrow spaces because of its compact design.

Request for a quote

KERMAK MACHINERY

Turkey

The machine parts are made of 304 AISI stainless chrome material. High pressure water pump 800 crate washing capacity per hour Pressurized water spraying on the case is provided by special spray nozzles. Speed controlled conveyor system Visor and safety bars that can be adjusted according to the size of the frame Removable side covers for easy cleaning Internal water tank with a capacity of 500 liters. Anti-clogging sediment collector mechanical screening system 380V 50Hz 10kw electricity requirement Speed control panel for conveyor Electric control control panel Machine total length is 4 meters Washing Tunnel length is 3 meters. Height 165cm Width 100cm + 30cm electrical panel It can wash up to 600 * 400 * 350mm sized crates.

Request for a quoteResults for

Spraying system - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Textile dyeing - machinery and equipment (3)

- Textile dyeing (2)

- Sawing machine tools (1)

- Paint spray guns and accessories (1)

- Agricultural systems and equipment (1)

- Axles, vehicle (1)

- Concrete constructions (1)

- Construction machinery (1)

- Cutting - machine tools (1)

- Farm machines (1)

- Food packaging (1)

- Oils, cooking - machinery and equipment (1)

- Refuse handling - machines and systems (1)

- Sports equipment (1)

- Storage and collection of waste - equipment (1)

- Waste transportation (1)

- Waste treatment and recycling - machines and installations (1)