- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servo motors

Results for

Servo motors - Import export

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Yaskawa motors,drivers,PLC and I/O boards are used in various different industries in order to maintain continous production. CIMR-AB4A0208ABA Yaskawa Best vfd drives Variable Frequency Drive CIPR-GA70B4168ABBA Yaskawa,Frequency Converter VFD SGMGH-1EDCA6C Yaskawa Servo Motor · SIGMA-II · High Speed Type · 15 KW CIMR-AC4A0139AAA Yaskawa Vector Inverter; Max motor power: 55/75kW Cımr-Ab4A0139Aba Yaskawa Drive · Cipr-Ga70B4140Abba Yaskawa Servo Drive CIMR-AB4A0103ABA Yaskawa Inverter A1000 series CIPR-GA70B4103ABBA Yaskawa Inverter CIMR-AB4A0088ABA Yaskawa Frequency Inverter SGDH-15DE-OY Yaskawa Servo Drive CIMR-AB4A0072ABA Yaskawa A1000 series Inverter CIPR-GA70B4075ABBA Yaskawa Inverter CIMR-AB4A0058ABA Yaskawa A1000 30kW/22kW Inverter JANCD-NCP01-1 Yaskawa Motoman NX100 CPU Robot Control Board

Request for a quote

PGR DRIVE TECHNOLOGIES

Turkey

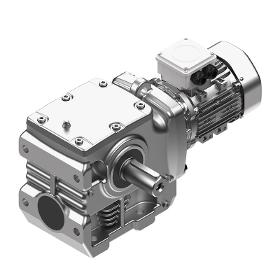

Helical and worm gear units with 90° input and output axis range. Casing with feet, flange F options Rigid case structure and suitable for heat transfer. System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards. Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...). Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

Request for a quote

PGR DRIVE TECHNOLOGIES

Turkey

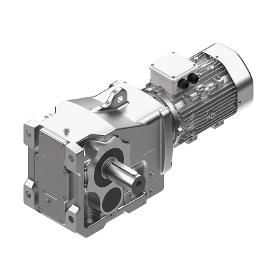

Helical bevel gear units with 90° input and output axis range. Casing with feet, flange F options. A rigid structure in case. System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards. Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...). Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

Request for a quote

ÖZKA MACHINE AUTOMATION

Turkey

Photocell Control For Jumbo Film Rupturing Jumbo Edge Motor Control System Edge Folding System Adjustment Oscillation System (Synchronous With Machine Speed) Servo Motor Controlled Rewinding System Omron Brand Servo Motors Omron Brand Plc System Omron Brand 7" Touch Panel

Request for a quote

KUZEY GLOBAL

Turkey

4 Column cutting station 80mm diameter resistant shafts in each column Lower and upper independent servo motor station groups Cutting right – left and forward – reverse motorized adjustment system Max 780°C cutting blade temperature and insulation plate. Fast blade damping system Cutting group stroke lower/upper 750 mm Needle bearing system Piston upper group dearance system Compression force 60 tons

Request for a quote

DAMS MACHINE

Turkey

Sandwiches and burgers which are coming from the cooling unit are placed between the alignment units by two staff manually or automatically with unmanned feeding system. The aligned products are divided into groups of 4.5 and 6, thanks to two valves. The number of products is controlled by the sensors during the separation of the products and the control continues until it is finished. If desired; the slicing process takes place with the slicer system and the products reach the packaging for all grouped products. The products that reach the packaging are transferred to the relevant unit through the robot arm. The packaging unit is controlled by a single servo motor.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Easy operation and clear visualization (test curves, calculations) via integrated touch display 16″ Easy to change the grips via malefemale connection Accuracy ±0.5% of full scale Precise, selfcleaning ballscrew Brushless servo motor quarantine maintenancefree operation Easy calibration of loadcell Socket connection of extensometer as standard option

Request for a quote

AHP PLASTIK MAKINA

Turkey

The universal tensile tester is used for performing tension, pressure or bending tests. The classic application is the tensile test. This involves subjecting a sample to an increasing tensile load until it breaks. According to ISO 527 , ISO 6259 , ASTM D 638 , servo controlled , long travel extensometer , ball screw , double column , USB computer controlled , windows based software • - Easy operation and clear visualization (test curves, calculations) via integrated touch display 16″ • - Easy to change the grips via male-female connection • - Accuracy: ±0.5% of full scale • - Precise, self-cleaning ball-screw • - Brush-less servo motor quarantine maintenance-free operation • - Easy calibration of load-cell • - Socket connection of extensometer as standard option

Request for a quote

AHP PLASTIK MAKINA

Turkey

The universal tensile tester is used for performing tension, pressure or bending tests. The classic application is the tensile test. This involves subjecting a sample to an increasing tensile load until it breaks. Servo controlled , long travel extensometer , ball screw , double column , USB computer controlled , windows based software • - Easy operation and clear visualization (test curves, calculations) via integrated touch display 16″ • - Easy to change the grips via male-female connection • - Accuracy: ±0.5% of full scale • - Precise, self-cleaning ball-screw • - Brush-less servo motor quarantine maintenance-free operation • - Easy calibration of load-cell • - Socket connection of extensometer as standard option

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continiously. Auotamic lateral adjustment of wrappin material. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Volumetric filling system is suitable for products which are able to free falling and homogeneous in density.the Weight of each filling is controlled by adjusting the dimensions of filling cups. Different cups with adjustable dimension should be used for different type of products.The sensitivity of target weight is equal to sensitivity of product density. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continuously. The wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continuously. Automatic lateral adjustment of wrapping material. Suitable for CE standards. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter Changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. · Sutiable for quadseal packages · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. · Printer state is checked continiously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. · Wrapping material tension is controlled continiously. · Auotamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continiously. Auotamic lateral adjustment of wrappin material. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlledwith fast and accurate servo driven specific auger (wormscrew). The auger type and diameter changes with respect to product type and target weight. · All surfaces touching to products are AISI 304 stainless steel. · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. Printer state is checked continously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. · Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. · Autamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The weighing unit is controlled by a seperate microprocessor and touch screen.Supports many usefull functions such as multi dumping, automatic product conveyor control, self cleaning, recipe record for different products, different language and etc. Different amount of weighing buckets in different dimensions should be provided with respect to type of product. Parts touching to products are easy to dismount and cleaning. All surfaces touching to products are AISI 304 stainless steel. Sutiable for quadseal packages Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. Auotamic lateral adjustment of wrappin material.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INO MACHINERY

Turkey

Double Mitre Saw with 600 mm sawblades and 6 meter cutting length; customized for aluminium profiles. Second head moving on linear guides via rack&pinion and servo drives. Both heads tilting inside 45 to outside 22.5 and 90 degrees all inbetween degrees are adjusted electronically through servo motors and harmonic reducers. The advanced reducer technology that we use on this mechanism allows the servo motors work with zero backlash and maintain the most precise angular adjustment. Thanks to the fixed roller conveyor mounted on the secondary head and the manual supports, the profiles are placed on the machine easily and cut perfectly.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing aluminium profiles. Apart from aluminium, it can also process any light alloy profiles with the help of dedicated customized cutters. The bridge carrying the high-speed electro spindle moves on linear guides by the brushless servo motors independently from the drive and processes any shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic reference point tilts up and down automatically according to the machine’s working cycle.4 pieces of profile clamping units are positioned manually by the operator according to the places that the CADCAM decides.

Request for a quote

INO MACHINERY

Turkey

CNC profile machining center with economical design cabin moving on X-Y-Z axes. It can work on aluminum and PVC profiles. Specially designed for door and window profiles. It works on profiles with a high-speed spindle moving on a steel body equipped with a CNC controller unit and servo motors. The reference point at the beginning and end of the machine is lifted manually and determines the zero point of the profiles. Profile clamping pneumatic vices are placed on linear guides in 4 units as standard equipment. It works with Uni_Link, customized software for door&window manufacturing, and the clamp positions are displayed on Uni_Link’s own interface. Thanks to the Uni_Link program, Dxf drawings of door and window profiles are exported to the machine HMI. The size of the door profile to be processed is entered, hinge type, lock type is selected, and the machine performs parametric calculations on the profile perfectly.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing on aluminium profiles. Apart from aluminium, it can also process any kind of light alloy profiles with the help of dedicated customized cutters. The bridge that is carrying the high speed electrospindle is moving on linear guides by the brushless servo motors independently from the drive and process any kind of shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic referance point tilt up and down automatically according to the machine’s working cycle.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

YILMAZ MACHINE

Turkey

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor Remote connection via internet and providing technical support

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

CMS GLASS MACHINERY

Turkey

Servo motor driven automatic glass sealing robot carries out the final sealing of the insulated glass units, providing accurate sealing of the angles and assuring high operating speed. With its robotic structure, the machine automatically can seal double, triple and structural (step, facade) glasses with maximum quality.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

2 Color Online printing machine for production lines. Servo motor driven , SIEMENS 7" Touch Control Screen and PLC controlled automation systems added. Ink pump & Ink tank for each color group included .

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

STRIP SIZING MACHINE CAN BE 2 TO 8 HEADS. BELT WIDTH 70 CM. IT IS FULL AUTOMATIC WITH ALL SERVO MOTOR.

Request for a quote

HF HAYTEK PLASTIC AND PLASTIC MACHINERY CO.

Turkey

Independently driven caterpillars using Asynchronous and Servo motors. They allow a constant pulling power. Furthermore, they reduce energy waste and the number of moving parts subject to maintenance. Long caterpillar contact length assures a good grip on the pipe and provides considerable pulling power. Caterpillars bow profile. The shape reduces stretching and wear of the caterpillars, thus prolonging the life of the machine. Motorized positioning of lower caterpillars that can be adjusted according to the diameter. Chain conveyors with neutral rubber pads on chains that do no mark the pipe. High torque can be obtained at low line speeds in servo motor haul off.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

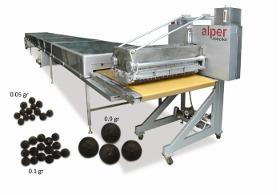

rop Line Chocolate drop size can be adjusted between 0.05 to 0.9 gr Each drop has its own piston Depositor has high precision since dosing is done by servo-motors. Depositor hopper is double jacketed and temperature controlled Depositor has agitator Easy cleaning PLC controlled Capacity: 33-600 Kg/hour

Request for a quoteResults for

Servo motors - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Food industry packaging machinery (6)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (5)

- Bakery and confectionery industry - machinery and equipment (3)

- Cocoa and chocolate - machines and equipment (2)

- Handling - Machines & Equipment (2)

- Testing equipment (2)

- Packing and packaging - machinery and equipment (1)

- Electrical & Electronic Components (1)

- Agglomeration and emulsification machines for the food processing industry (1)

- Cardboard - manufacturing machinery (1)

- Control panels - electric (1)

- Double glazing (1)

- Flexography - machines (1)

- Marble cutting machines (1)

- Roller shutters (1)

- Sugar refineries - machinery and equipment (1)

- Tapping - steels and metals (1)

- Tubes and pipes, rubber and plastic (1)

- Wrapping machines (1)