- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plc programming

Results for

Plc programming - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

It is the furnaces where the hardening process of various aluminum profiles is happened, in other words, the aging process. Aluminum profiles are loaded into the furnace with the help of loading cars. The profiles which are kept in the oven at about 185 °C for 6-8 hours will be harden with the aging process. The whole operation is programmed with the PLC control unit. Thanks to its safe guillotine doors, they contribute to the air circulation in the interior and provide security with the locking mechanisms.

Request for a quote

DAMS MACHINE

Turkey

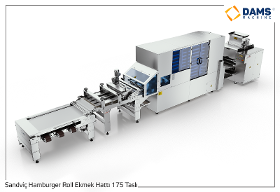

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional)

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

ONURAY

Turkey

HT BEAM and ROTARY HT BEAM Fabric Dyeing Machines are a NEW TECHNOLOGY developed by ONURAY and allow flawless dyeing of all kinds of fabrics at low cost. It can be produced in different widths and capacities. (100,200,400,800 kg) Low liquor ratio ( 1/3 – 1/4 ) Internal washing and spraying system. Safe cover system. Flap system that allows bidirectional (exterior-interior / interior-exterior) operation. PLC Programmed dosing and mixer. Rapid Discharge Electronic speed-controlled pump. Fully automatic PLC controlled working program.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ONURAY

Turkey

SAMPLE HT BOBBIN DYEING MACHINE The Sample HT Bobbin Dyeing Machines are produced in different capacities between 1 bobbin to 10 bobbin capacities using AISI 316 quality Cr-Ni material. Sample bobbin dyeing machines, produced with air pad or overflow system, provide error-free and repeatable dyeing and finishing processes in order to be fully compatible with the machines in the plant. It can be controlled manually or fully automatically, depending on demand, and PLC programmed dosing can be done with the dosing pump and its programs. It has high technological safety equipment. (Mechanical, Electronic and Electro-Mechanical)

Request for a quote

ONURAY

Turkey

HT Bobbin dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in bobbin form. It is produced in different capacities (1 bobbin to 2000 bobbins) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

The Sample Package Yarn Dyeing Machines are produced in different capacities between 1 cone to 10 cone capacities using AISI 316 quality Cr-Ni material. Sample yarn dyeing machines, produced with air pad or overflow system, provide error-free and repeatable dyeing and finishing processes in order to be fully compatible with the machines in the plant. It can be controlled manually or fully automatically, depending on demand, and PLC programmed dosing can be done with the dosing pump and its programs. It has high technological safety equipment. (Mechanical, Electronic and Electro-Mechanical)

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

HT YARN DYEING MACHINE HT Package dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in cone form. It is produced in different capacities (1 cone to 2000 cones) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

It is produced for weaving and knitting /lycra fabrics from 5Kg capacity to 1200 kg capacity. The interchangeable flattening system provides full compatibility with operating machines with optional full or semi-automatic program control, PLC programmatic dosing.

Request for a quote

BAYKON INDUSTRIAL WEIGHING SYSTEMS

Turkey

TX4 digital transmitter family is designed for static or dynamic weighing and force measurement processes to provide fast and accurate digital data through RS-232C, RS-485, Ethernet TCP/IP and bus systems as Profibus, Modbus TCP, Modbus RTU, Profinet, CANopen, EtherNet/IP, EtherCAT, CC-Link, Powerlink. TX4 transmitters have a parallel port including 1 x Output and 2 configurable as Inputs or Outputs which can be controlled directly by PLC. TX4 transmitters are programmed and calibrated via PC by BAYKON xFace software. Weighing functions such as Zeroing, Taring, Power-On zero, net indication at power on, Motion detection, configurable vibration suppression digital filter and electronic calibration without test weights ( eCal ) are important features. DIN rail type enclosure provides easy montage in control panel.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 PLUS Block and Paverstone Machine is special design machine for block and interlock production that works fully automatic.The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of blocks, paverstones, curbstones, grass stones, lentos and precast concrete elements can be produced in a serial way. 20cm block can be produced 15, interlock paverstones can be produced 36 units in one press. Machine is able to produce the insulated block upon demand. Thanks to special features developed by our engineers machine have very short cycle time. For example mould changing is wery easy and take short tme in new system. Automation system and operator panel which is developed and redesigned in long years become user friendly and useful. With our special design vibration table you can produce high quality products with less energy. We use pneumatic bellows in machine mould connections.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1230 Concrete Pavers and Block Making Machine; It is a machine that works fully automatic. The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of pavers stone , curbs, block and precast concrete elements such as grass pavers series can be produced in a serial way. 20cm block can be produced 12 units in one press with the machine,or 30 interlock stones can be produced in a press. Machine is able to produce the insulated block upon demand. Our company’s special production vibrator is used. Thus, it can produce smoothly and quickly. Pneumatic bellows cylinders are used in connection of the mold of the machine. In this way a more uniform vibration propagation in the mold is obtained. Other than the mold and the press, thin and the bold mortar sections are moved over the hard chromium-plated column mills as well.

Request for a quoteResults for

Plc programming - Import exportNumber of results

15 ProductsCountries

Company type

Category