- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plc programming

Results for

Plc programming - Import export

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. We strive for clearly structured program sequences. User interfaces should be as self-explanatory as possible and intuitive to operate. It is also important to have a well thought-out concept for user authorizations and parameter management.

Request for a quote

HORNER AUTOMATION IRELAND

Ireland

15” TFT Colour All-in-One Controller with dual Ethernet & CAN and Integrated I/O. 15″ high-resolution touchscreen display High-speed dual core processor 2 x 10/100/1000 (Auto-MDIX) Ethernet LAN ports 3 RS232/RS485 serial ports 3 CAN ports 3 x USB A ports and 1 x USB mini-B port Built-In Digital and Analogue I/O with quad 500kHz high-speed counters Mic and audio connectors Support for 1080p resolution full-screen video streaming and playback Polycarbonate overlay for improved touchscreen durability 6 Models available, 5 with varying I/O 1 model without I/O

Request for a quote

HORNER AUTOMATION IRELAND

Ireland

Cscape Free PLC software combines graphical ladder diagram programming (based on IEC-1131) with operator interface development to completely integrate the control package. 1Integrated IEC languages10 Relay Ladder Logic Floating Point Maths Motion Commands Serial Read and Write Functions I/O Configuration Auto Tune PID Modem & Networking Functionality

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

From the design phase of your project, we take care of installing all the electrical and electronic components: electrical studies PLC studies and programming production of electrical diagrams, wiring and installation logbooks wiring of power cabinets, control cabinets (automation), pneumatic cabinets and frames installation of cable trays on-site connection final inspection, power up and validation

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

From the design phase of your project, our specialist technicians take care of the study and integration work for all the PLC and IT parts needed to manage and control your future facility: PLC studies and programming Integration of instrumentation and regulation on-site connection Final control and validation

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

It is the furnaces where the hardening process of various aluminum profiles is happened, in other words, the aging process. Aluminum profiles are loaded into the furnace with the help of loading cars. The profiles which are kept in the oven at about 185 °C for 6-8 hours will be harden with the aging process. The whole operation is programmed with the PLC control unit. Thanks to its safe guillotine doors, they contribute to the air circulation in the interior and provide security with the locking mechanisms.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

CODESYS Starterkit HMI Extension Easy visualization. Each Kuhnke CODESYS Starterkit can easily be extended by a CODESYS HMI Touch display. Only connect the display to the Starterkit via an Ethernet cable, connect in with power supply and download a project on the HMI device. The programming, the connection of the program with the PLC as well as the steps to create an own visualization are explained in detail by several examples that can be downloaded comfortably in our download area.

Request for a quote

DYMAX EUROPE GMBH

Germany

The BlueWave® FX-1250 is a high intensity LED flood-curing system that delivers true, high irradiance LED light for the best speed, depth, and fullness of cure from Dymax LED emitters. For the user who needs flood curing systems for large areas, the unit combines intensities over 2W/cm2, with a 5” x 5” (127 mm x 127 mm) curing area and high uniformity to provide a superior cure. Features - High intensity, high total irradiance for quick curing - Large 5” x 5” (127 mm x 127 mm) curing area - Excellent uniformity - One controller operates up to two channels - LED heads for 365, 385, or 405 nm wavelengths - Fully programmable and can store up to 16 programs - PLC touch screen interface that easily incorporated into automated systems - Efficient LED temperature management for continuous operation without overheating - Instant on-off – no warm-up period and more energy efficient - Cross platform compatibility with UVCS V3.0 LED conveyor system

Request for a quote

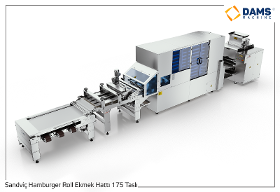

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional)

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

PRO-ASSEM SP. Z O.O.

Poland

PLC drivers programming Modification of the existing programs Preparation of the vision applications

Request for a quote

GAICTECH

Spain

The Tuna Fish Steam Cooker is expertly designed to refine the production process for tuna, focusing on increasing total fish yield through precise thermal gradient control and moisture content preservation. This ensures the fish remains moist, facilitating easier cleaning post-cooking. Tailored for flexibility, it offers adaptations for client-specific trolleys and the option for cooking without vacuum, enhancing its utility in diverse processing environments. Remote support capabilities allow for diagnostics and adjustments via PC and Ethernet, ensuring seamless operation and troubleshooting. Constructed from high-quality stainless steel AISI 304 L, the cooker is built for durability and hygiene compliance. Key features include a fully automatic cooking cycle, options for time or temperature-driven cooking directly in the fish's bone, and advanced process control via the latest generation PLC with exclusive tuna cooking programming. Temperature monitoring through thermocouple

Request for a quote

ONURAY

Turkey

HT BEAM and ROTARY HT BEAM Fabric Dyeing Machines are a NEW TECHNOLOGY developed by ONURAY and allow flawless dyeing of all kinds of fabrics at low cost. It can be produced in different widths and capacities. (100,200,400,800 kg) Low liquor ratio ( 1/3 – 1/4 ) Internal washing and spraying system. Safe cover system. Flap system that allows bidirectional (exterior-interior / interior-exterior) operation. PLC Programmed dosing and mixer. Rapid Discharge Electronic speed-controlled pump. Fully automatic PLC controlled working program.

Request for a quote

ONURAY

Turkey

ECO-DYE HT Jet Fabric Dyeing Machines are specially designed to dye cotton, viscose or blends sensitive to friction in the best way possible. It can be produced in high and variable capacities. It can be produced in high and variable capacities. (300 kg- double cabin in single body) Low liquor ratio (1/4 – 1/6) High fabric cycle speed (500 m / min) Internal washing and spraying system. Safe cover system. Variable nozzles Wide surface filter. Teflon Coated J-Boxes. Dosing and mixer with PLC program. Rapid discharge Electronic speed-controlled pump. Fully automatic PLC controlled working program.

Request for a quote

ONURAY

Turkey

SAMPLE HT BOBBIN DYEING MACHINE The Sample HT Bobbin Dyeing Machines are produced in different capacities between 1 bobbin to 10 bobbin capacities using AISI 316 quality Cr-Ni material. Sample bobbin dyeing machines, produced with air pad or overflow system, provide error-free and repeatable dyeing and finishing processes in order to be fully compatible with the machines in the plant. It can be controlled manually or fully automatically, depending on demand, and PLC programmed dosing can be done with the dosing pump and its programs. It has high technological safety equipment. (Mechanical, Electronic and Electro-Mechanical)

Request for a quote

ONURAY

Turkey

HT Bobbin dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in bobbin form. It is produced in different capacities (1 bobbin to 2000 bobbins) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Sleeve Shrink Wrap Machine is made to wrap heavy products with thick film.The finished packaging has two open ends on each side which are referred to as "bullseyes". Standard products packaged with a shrink bundling machine include firewood, canned goods, cases of water bottles, metal products, tool cases, and more. The machine can carry out two-row, three-row, four-row shrink packaging with or without bottom support,like 10 bottles (1 × 10), (2 × 5), 9 bottles (3 × 3), 12 bottles (3 × 4), 15 bottles (3 × 5), 24 bottles (4 × 6). Using worm gear reducer, products feeding and film feeding smooth without jitter. Adopt "Siemens" "PLC" program controller to realize the integration of machine, electricity and gas.Using worm gear reducer, products feeding and film feeding smooth without jitter.Specially designed sealing knife, the sealing line is firm, not cracked, and not easy to stick to the knife.The frequency converter controls the transmission speed.

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm ActivePLC™ provides a single, universal process control platform that can be standardized on many different applications, machines and projects, reducing development time, training, and spare part requirements. This industrial standard programmable logic controller runs on the Protherm ActivePLC™ process control platform with its universal PLC program that is ready to run “out of the box” without PLC programming required. The platform provides a completely flexible and uniform system to define and setup inputs, outputs, alarms, timers, advanced math functions, logic operations, PID loops, recipe operation, analog signal scaling, and even thermocouple type selection and calibration on an industry standard controller. Configuration is accomplished via the Protherm ActiveHMI™ touchscreen. Settings and logic can be backed up locally and replicated to any other Protherm ActivePLC™ hardware regardless of the manufacturer. FEATURES • Customizable HMI • Data Logging and...

Request for a quote

NORIS GROUP GMBH

Germany

Robust CPU I/O master module with powerful 32-bit processor Controls up to 16 I/O slave modules Robust design for harsh environments (shipbuilding approvals) Integrated web server for user-friendly configuration and web-based visualisation IEC 61131 compliant PLC that can be flexibly programmed (CODESYS) Integrated 32 GB SD card (e.g. logging function) and USB interface Ideal for use in shipbuilding thanks to approvals from classification societies

Request for a quote

NORIS GROUP GMBH

Germany

Robust CPU I/O master module for offshore applications I/O master module with powerful 32-bit processor Extremely robust design, suitable for the offshore sector and underwater technology Interface with underwater acoustic modems IEC 61131 compliant PLC that can be flexibly programmed with CODESYS Plug-in underwater connections Maximum depth down to 6,000 m

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The knives of knife-ring akers have to be sharpened and re-set at regular intervals. This can be a very timeconsuming and personnel-intensive job. The quality and precision of these tasks depend strongly on the accuracy and dedication of the individual worker. With the sharpening and setting robot PZSE the knives can be sharpened and set automatically. Features, Function safety housing fully automatic process ow transport to and clamping of the knife ring to the carrier disc determining the wear of all parts automatic readjustment of all wear shoes and knives sharpening of all knives in a wet grinding process cleaning torque control of clamping bolts detection of possible damage to the threads Advantages automatic sharpening and setting process setting of the knives with high accuracy electronic control of tightening torque of the knife xing bolts automatic monitoring of the thread quality of the xing bolts preventative maintenance program thanks to PLC-controlled integrated

Request for a quote

VELTRU AG

Switzerland

2-axis execution Top mounting Work range: y = 1000 mm, z = 300 mm Payload: to 6 kg For standard applications, VELTRU offers a toploading application ready to use. As all VELTRU applications, the open source PLC program could be adapted to specific customers' needs. For standard applications, the setup and commissioning can be done by interactive GUI only, without any programming. Contact us for more details!

Request for a quote

VELTRU AG

Switzerland

PLC programming technologies are widely used for development of control circuits in the packaging and assembly machinery industry. VELTRU therefore focuses their development on current PLC technology. Time critical and motion related functionalities, such as path planning, motion interpolation, and robot coordinate transformations for all VELTRU and custom robot kinematics are realized strictly in IEC 61131-3. This widely applied and used programming standard provides several benefits: • One single programming tool for all automation issues including robotics • Powerful and well-known tools for the application development • Integrated visualization modules for the developer and for the end user

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

The Sample Package Yarn Dyeing Machines are produced in different capacities between 1 cone to 10 cone capacities using AISI 316 quality Cr-Ni material. Sample yarn dyeing machines, produced with air pad or overflow system, provide error-free and repeatable dyeing and finishing processes in order to be fully compatible with the machines in the plant. It can be controlled manually or fully automatically, depending on demand, and PLC programmed dosing can be done with the dosing pump and its programs. It has high technological safety equipment. (Mechanical, Electronic and Electro-Mechanical)

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

HT YARN DYEING MACHINE HT Package dyeing machines are equipped with high technology that enables dyeing of any type of fiber made yarn in cone form. It is produced in different capacities (1 cone to 2000 cones) completely from AISI 316 quality Cr-Ni material. The maximum operating temperature is 140 ºC and the working pressure is designed as 4 Bar. The machines are equipped with high safety equipment (Mechanical, Electronic, Electro-Mechanical). Fully automatic machines with PLC control system have 5 ºC / min heating, 3 ºC / min cooling capability and can do chemical and dye dosing with PLC program. It is possible to dye muff, tops and fiber or yarn in different forms with different apparatus applications on the same machines.

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

It is produced for weaving and knitting /lycra fabrics from 5Kg capacity to 1200 kg capacity. The interchangeable flattening system provides full compatibility with operating machines with optional full or semi-automatic program control, PLC programmatic dosing.

Request for a quote

NORMIT

Slovakia

FEATURES: multi-zone tempering system provides efficient heat exchange and the formation of stable coca butter β-crystals. measurement of inlet and outlet temperatures in each zone PLC control panel, accurate correction program temperatures the unique design of the scaler and discs guarantees uniform mixing manufacturing material AISI 304 or 316 Constant viscosity glaze The glaze, after passing through the machine, has a constant viscosity, gives a perfectly glossy surface when cured and becomes stable (the glazed product does not melt in the hands). PRODUCTS: dark chocolate milk chocolate icing cocoa butter ADDITIONAL OPTIONS: chiller de-crystallizer

Request for a quoteResults for

Plc programming - Import exportNumber of results

34 ProductsCountries

Company type

Category

- Textile dyeing - machinery and equipment (7)

- Textile dyeing (5)

- Bakery and confectionery industry - machinery and equipment (3)

- Automation - systems and equipment (2)

- Motor mechanics - hand tools, non power (2)

- Packing and packaging - machinery and equipment (2)

- Adjustment - machine tools (1)

- Biomedical equipment (1)

- Chocolates, filled (1)

- Concrete preparing - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Electrical components and parts (1)

- Marine, port and underwater works - contractors (1)

- Paint spray guns and accessories (1)

- Palletising machinery (1)

- Presses, hydraulic (1)

- Steam polishers (1)

- Tile-making - machinery and equipment (1)

- Valves for pneumatic equipment (1)

- Weighbridges (1)