- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining unit

Results for

Machining unit - Import export

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

In our Machining Unit, all kinds of materials can be processed serially with the desired precision using CNC machines in accordance with the constantly advancing world technology.

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Phoenix Machinery Hygiene Converting Division manufactures and retrofits Diaper Machines with the following equipments: Low Waste Back Ears Unit (BEU) Frontal Tape Cut & Place (FTCP) Refastenable Tape Cut & Place (RTCP) Sublayer Cut & Place (SLCP) Horizontal Stacking & Counting System (HSC) Backsheet Lamination Unit (BLU)

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

Scaffolding making machine line is the machine line, which for production of scaffolded metal boards for construction industry. Scaffolding Machine Line General Units Decoiler Straightener and Feeder Eccentric Press Roll Form Unit Stacking Unit For high speed scaffolding panel production results and for matching with our customers scaffolding panel design, we use continuously scaffolding roll forming machine on our scaffolding machine line. On roll forming unit, station quantity and rollform roller diameters are designed according to our customer’s scaffold board design. The scaffolding roll forming unit will be designed for having the best results. Also our eccentric presses have all necessary capabilities and can do precision work during scaffold production. It will work synchronized with other scaffolding machine line units.

Request for a quote

TECHNIC MACHINES

Turkey

We offer suspended ceiling machine line which can produce the suspended ceiling with different thickness, width range production capacity and can work different raw materials. Also we design our tools for different suspended ceiling tile perforation patterns and panel types. As Lay-In, Clip-In and Lay-On suspended ceiling panels. And also we can produce our suspended ceiling tile production lines as to customer special request with until 2.000 mm width. Suspended Ceiling Machine Main Units – Press Feeding Unit – Perforation Press – Sheet Metal Cutting Unit – Conveyor Unit – Press Feeding Unit – Press for Notching and Bending So, machine units one by one as decoiler, straightener. servo feeder, press for perforation, cutting unit, conveyor, second straightener and feeder , press for bending and notching.

Request for a quote

TECHNIC MACHINES

Turkey

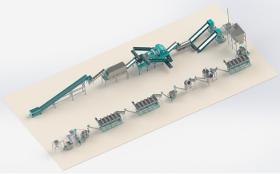

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Machine Oils MP represent a premium line of industrial extreme pressure gear and bearing oils engineered to resist micro-pitting. They have earned Flender’s approval and excel in applications where heavy loads, slow speeds, and elevated temperatures are commonplace. Machine Oils MP leverage a distinctive blend of ashless extreme pressure and anti-wear additives, resulting in a series of gear oils that meet Flender’s performance standards. These oils deliver robust protection against wear, corrosion, and oxidation, ensuring clean gear operation. They also demonstrate a propensity for minimal deposit formation and maintain high phosphorus levels over their lifespan, ensuring long-lasting safeguarding. Machine Oils MP exhibit outstanding anti-friction properties, making them ideal for use in bearings, steel transmissions, and gear units. Notably, Machine Oils MP are particularly well-suited for helical, bevel, and planetary gear units.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Meat and sausage is prepared wtih mixer afterwards they are moved by a lift and then they are dropped into machine. Machine has cooling unit which provides 4 Degree celsius for staying fresh meat and warm is controlled by plc. The machine has vacuum unit it ensures penetrate sauage into meat. meat tumbler mixer meat tumblers for sale meat tumbler ebay meat tumbler for sale south africa meat tumbler reviews meat tumbler recipes tumblr meat processing vacuum meat tumbler canada commercial meat tumbler what does a meat tumbler do how to build a meat tumbler biro meat tumbler meat tumbler canada meat compost tumbler countertop meat tumbler cabela's meat tumbler challenger meat tumbler diy meat tumbler electric meat tumbler vacuum meat tumbler for sale vacuum tumbler for meat processing meat tumbler ham hobart meat tumbler industrial meat tumbler lance meat tumbler meat vacuum tumbler manufacturers meat tumbler for sale philippines

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed. Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities. Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups. Double Embossing Technique: Ability to wrap products with two different embossing patterns. High Efficiency: Fast and uninterrupted production capacity. Flexible Production Options: Ability to process paper of different sizes and thicknesses. User Friendly Design: Easy operation and adjustable features.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Industrial Log Saw Cutting Machine plays an important role in the jumbo product production process in the paper converting industry. This machine is designed to cut large diameter toilet paper and kitchen towel rolls (logs) in specified dimensions and with high cutting precision. Jumbo products are toilet paper and kitchen towels used in the industry, which are generally large in diameter and tightly wound in the winding unit. This machine which is suitable for cutting jumbo rolls is equipped with advanced technologies to increase the speed and efficiency of the production process. Industrial Log Saw Cutting Machine is a high capacity machine used to cut jumbo rolls in specified sizes. With the eccentric cutting feature of the log saw blade and motor power, it cuts even very tightly wrapped rolls smoothly. High Cutting Speed and Precision: Capacity to make fast and precise cuts. Large Capacity: Ability to cut jumbo rolls smoothly and with little waste.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

Teknova washing liquids; they are designed to be used in modern web offset, sheet offset and flexo printing machines, manual and automatic washing units. They offer a strong cleaning performance. They are sensitive to human, machine, and environmental health with the preservatives in their formula. They have the international Fogra quality license.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Computercontrolled (CNC) test bar milling machine with installed machining programs and special clamping devices will prepare samples for tensile tests and other specific shaped sample required tests The CNC milling machine is a tabletop unit with protective doors. Preconfigured machining programs for all common sample shapes The allround enclosure ensures safety at the workstation The milling machine is optionally fitted with pneumatic clamping devices Test samples with a maximum length of 250 mm, a maximum thickness of 50 mm can be milled as standard. Optionally thickness of 100 mm is available. Delivered with workbench Test samples milled in accordance with standard dimensions Machined areas cooling with compressed air Highquality unit components guarantee long service time

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. A skid hydraulic system provides the user to shift the machine from the tractor’s control unit when the machine encounters a tree or a hard material. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed -7 mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -Hydraulic offset -36/42/48 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION FULL AUTOMATIC SCREWDRIVER MACHINE Pneumatic unit of automatic screw feeding Pedal control of automatic screwing Automatic stop after screwing Adjustable measure distance between the screw Protective sensor to prevent faulty use Height adjusment sensor for special screws Automatic clamping of profile during screwing Pneumatic range stops supporting profile Durable use of bit and easy change possibility Manual screw feed from the screen Average screwing speed 1.7 sec./pc TECHNICAL SPECIFICATIONS

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YILMAZ MACHINE

Turkey

KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles . The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the hydrauliccally crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the milimetricruler The machine is equiped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering setsquare returns to the home position under the table after crimping Powerfull hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scrathes on the profile surface

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles. The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the pneumatically crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the millimetric ruler The machine is equipped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering set-square returns to the home position under the table after crimping Powerful hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scratches on the profile surface

Request for a quote

NOVA KIMYA

Turkey

Usage Areas and Features: Provides powerful and effective cleaning of cylinders and screws of injection and extrusion machines. Cleans hot runner systems. It is also suitable for protective cleaning during machine shutdowns. A very high cleaning result is achieved with a low dosage. By saving time and cost, problem-free color and raw material conversion is achieved. It minimizes the number of wastage and faults. It minimizes the loss of expensive raw materials. Easy to transport, store and use. It is not necessary to mix, dry and change machine temperatures. It is not corrosive, caustic to the skin and not harmful to health. It is recommended by reputable machine manufacturers. Form of Use and Quantity: Check whether the machine temperatures are suitable for the ENJOYCLEAN type to be used. Remove the polymer to be cleaned completely from the machine and wipe the feeding unit. Use ENJOYCLEAN without mixing with other raw materials.

Request for a quote

HII

Turkey

Are stand-alone units that are not built-in for machines. This unit uses fluid to power a machine and transmit power from one location to another. It includes a reservoir of many different shapes and sizes, regulators, a pump, motor, pressure supply lines, and relief lines. Packages have multiple valve connections, which means they can operate a variety of machines using the appropriate valves. Mini power packs, on the other hand, are smaller in size and consist of a wide variety of simple mounts, making them extremely versatile. It offers a compact solution for a multitude of applications, often without the need for tube and reinforcement assembly. It is a functional design product with high performance gear pump and steel or plastic oil tank options. Special production on demand

Request for a quote

KUTES METAL

Turkey

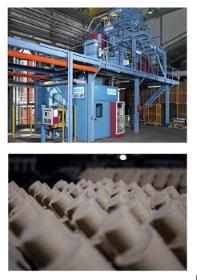

1 unit DISA 40 L. Core Machine 1 unit hottinger 25 L. Vertical Core Machine 1 unit hottinger 20 L. Vertical Core Machine 3 unit hottinger 12 L. horizontal Core Machine Laempe 9 ton/hour Sand Mixer Laempe 5 ton/hour Sand Mixer Laempe Sand Dosing Unit Laempe Central Amine GAs Unit Lazyou Double COnveyor Core Drying Oven

Request for a quote

KUTES METAL

Turkey

Shotblasting 1 Unit Wheelabrator Drum Type Continue Shotblasting Machine 1 Unit Georg fisher Drum Type Continue Shotblasting Machine 2 Unit Endümak Hang Type Continue Shotblasting Machine 2 Unit Endümak DrumType Continue Shotblasting Machine Grinding 2 Unit KOYAMA - P.S. Auto Grinding 400TTi 50 kg. • 2 Unit KOYAMA - P.S. Auto Grinding 400i 20 kg. • Manual Grinding Units

Request for a quote

KUTES METAL

Turkey

2 Unit DMG MORI NHX 5500 Horizontal Machining Center 2 Unit DMG MORI NHX 6300 Horizontal Machining Center DMG MORI NZX 2000 CNC Horizontal Turning Machine 2 Unit DOOSAN PUMA V 8300 M MODEL CNC VErtical Turning Machine DOOSAN DNM 5700 VErtical Machining Center DOOSAN PUMA GT 2100 M C axis horizontal Turning Machine Measurement Laboratory and material laboratory

Request for a quote

IMT MACHINERY

Turkey

Etcoma supplies complete Cable Tray Production Line for the production of all types of cable trays to carry the all kind of cables. All cable trays and their covers are produced in the roll forming line which is consisting of the decoiler, straightener, feeder, roll forming machine, punching unit, cutting machine and the stacking unit. Cable Tray means Cable trays carry various types of cables for power distribution, control, and communication. A cable tray system is the alternative to open wiring or electrical conduit systems which are commonly used for cable management in commercial and industrial construction.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine is designed to produce inter locks , blocks. insulated blocks, curbstone it can produce 140-150 pallet per hour 25 interlocks pcs/1 press 10 blocks pcs / 1 press press time is 25-30 seconed it has two system: full automatic and semi automatic it can be use with stacking system or with out stacked pallet must be transport with forklift for machine with stacking system. machine works on the wooden pallet there are two types of mortar reading system. It is manual and automatic weighing system cement water and sand weighn and mortar are mixed all motions on the machine provided by hydraulic system movements on the system will be controlled by PLC automation system via sensors in automaticmachine, machine press number unit of productions , problems on the machine can be seen on the PLC touchscreen panel.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce high quality of interlocks, blocks,curbstones and other concrete products as requested by the customer. One press can produce 42pcs of interlocks or 18 pcs from blocks 20x40x20cm block and curbstones. The machine can be used with a stacking system or without stacking system. The press time is 20-24 seconds. It has two working system, it can work either full automatic or semi automatic depending on user preference. Movements on the system will be controlled by a PLC. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood. There are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce interlocks,blocks,curbstones and other concrete products as requested by the customer. In one press it can produce 36 pcs of interlocks, or 12 pcs of 20x40x20cm block The press time is 18-22 seconds. It has two working system, it can work either on full automatic or semi automatic depending on user preference. The machine can be used with a stacking system or without a stacking system. Movements on the system will be controlled by plc. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood there are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed then transported up to the mixer.

Request for a quote

OZSTAR NUTS ROASTING MACHINERY

Turkey

Nuts roasting machine provides you the highest quality flavor for all kinds of nuts products such as sunflower seeds, peanuts, shelled peanuts, hazelnuts, shelled hazelnuts, pumpkin seeds, almonds, shelled almonds, pistachios, internal pistachios, and cashews. This world-class electric nuts roasting oven with advanced automation and control mechanism offers you a flawless production. With the help of energy-saving burners, it reduces the production cost by providing fewer manpower requirements and provides you with excellent results in every cooking process. There are a total of 7 roasting chambers in the belt type roasting machine. 4 of them were designed by our engineers for roasting, 1 for resting, and 2 for cooling. The pallet roasting machine is powered by four fully automatic two-stage high-efficiency gas burners. These burners are built to the highest standards for reducing pollutant emissions.

Request for a quoteResults for

Machining unit - Import exportNumber of results

34 ProductsCountries

Company type

Category

- Brick-making - machinery and equipment (3)

- Metal industrial presses (3)

- Rolling mills - machinery and installations (2)

- Machine tools, metal machining - parts and accessories (1)

- Plastics - machines and material for industry (1)

- Food Processing (1)

- Agricultural machines and accessories (1)

- Baby-care products (1)

- Blades for saws and cutting machines (1)

- Control panels - electric (1)

- Coring machinery (1)

- Crimping machines (1)

- Detergents and soaps - professional (1)

- Flour milling - machinery and equipment (1)

- Greases, industrial (1)

- Grinding - steels and metals (1)

- Industrial Vehicles (1)

- Laser - cutting and welding machines (1)

- Metallurgy - machinery and installations (1)

- Offset printing (1)