- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining unit

Results for

Machining unit - Import export

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Phoenix Machinery Hygiene Converting Division manufactures and retrofits Diaper Machines with the following equipments: Low Waste Back Ears Unit (BEU) Frontal Tape Cut & Place (FTCP) Refastenable Tape Cut & Place (RTCP) Sublayer Cut & Place (SLCP) Horizontal Stacking & Counting System (HSC) Backsheet Lamination Unit (BLU)

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

Scaffolding making machine line is the machine line, which for production of scaffolded metal boards for construction industry. Scaffolding Machine Line General Units Decoiler Straightener and Feeder Eccentric Press Roll Form Unit Stacking Unit For high speed scaffolding panel production results and for matching with our customers scaffolding panel design, we use continuously scaffolding roll forming machine on our scaffolding machine line. On roll forming unit, station quantity and rollform roller diameters are designed according to our customer’s scaffold board design. The scaffolding roll forming unit will be designed for having the best results. Also our eccentric presses have all necessary capabilities and can do precision work during scaffold production. It will work synchronized with other scaffolding machine line units.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNIC MACHINES

Turkey

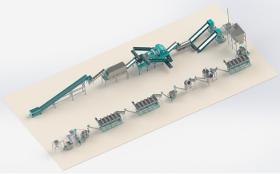

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quoteResults for

Machining unit - Import exportNumber of results

8 ProductsCompany type