- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines for washing plastics

Results for

Machines for washing plastics - Import export

TECHNIC MACHINES

Turkey

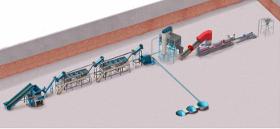

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

TECHNIC MACHINES

Turkey

We offer our Plastic Extruder Machine Lines for various industries, including construction, food, healthcare, white appliances, and automotive sectors. The most common raw materials used on our plastic extrusion machine lines include PVC, HDPE, PET, EPDM, PP, EPS, LDPE, PE, ABS, PC, PS, and others. We provide as standard Plastic Extruder Machine Lines WPC Extrusion Machine Strap Extrusion Machine Sheet Extruder Machine Rattan Extrusion Machine Polystyrene Extruder Machine Polycarbonate Extruder Machine Edge Band Extrusion Line Gasket Sealing Extrusion Machine As Technic Machines, we offer our customers optimal solutions for their specific needs in plastic extruder machine research. We provide custom solutions using twin screw extruders, single screw extruders, triplex extruders, or co-extruders. Our specialized extrusion line solutions are tailored to the final product requirements of our customers.

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Dolfin RTS series Rotational basket washing machines, washing small and complex surfaces It is a compact parts washing machine used for precise and high-level cleaning of problematic part types. The parts that are placed in the washing basket one by one by positioning and / or in bulk are first sprayed with alkaline chemical washing liquid at high pressure to every point of the parts in the device. Then the washing cell is filled with this liquid and the parts are contacted with ultrasonic sound waves. Therefore, thin section detail points, internal holes and channels are cleaned at a high level. In the process, the basket is rotated on the vertical axis and both spraying and ultrasonic effect is penetrated to every point of the part. At the end of this process, the washing liquid is directed to its own tank, while the same process is applied for rinsing and/or liquids in the other tank.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Dolfin KNV series conveyor belt washing machines are parts washing machines used for washing parts produced in series in large quantities. The parts placed at the entry point are moved towards the exit point of the device by means of the conveyor. The parts guided on the conveyor line are washed with high pressure, pre-washing, washing, rinsing, spraying with passivation liquids. At the end of the cleaning process, these parts are dried with pressurised hot air and discharged at the exit point. If desired, it can be integrated into production processes and robotic loading and unloading options are also available. While the entire device is fully automatic, all washing details are parametric. Cleaning is provided at any desired level by means of spray nozzles specially designed according to the part geometry.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

"DOLFİN- VDL series Drum (Spiral) parts washing machines are used especially for cleaning small parts with high production quantities and produced in bulk. The materials poured from the inlet part of the spiralised drum in the device are directed towards the outlet part of the drum by the spirals inside the drum. While the drum moves on its own axis according to the set rotation speed, the parts are subjected to washing (degreasing), rinsing, passivation and drying processes respectively (depending on the model). Since these processes are sequential and continuous, all processes are completed quickly and effectively in a single device. Full penetration is achieved by pressurised spraying and immersion effects in each section. It is a very functional model used especially for washing bolts, nuts, washers, or small parts of this type, and fittings, nipples, couplings and fittings processed in high quantities on cnc and automat machines.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN- VDL series Drum (Spiral) parts washing machines are used especially for cleaning small parts with high production quantities and produced in bulk. The materials poured from the inlet part of the spiralised drum in the device are directed towards the outlet part of the drum by the spirals inside the drum. While the drum moves on its own axis according to the set rotation speed, the parts are subjected to washing (degreasing), rinsing, passivation and drying processes respectively (depending on the model). Since these processes are sequential and continuous, all processes are completed quickly and effectively in a single device. Full penetration is achieved by pressurised spraying and immersion effects in each section. It is a very functional model used especially for washing bolts, nuts, washers, or small parts of this type, and fittings, nipples, couplings and fittings processed in high quantities on cnc and automat machines.

Request for a quote

EUROMACK

Turkey

AREAS OF USE - Automotive industry - Aircraft industry - Ship industry - Defense industry - Metal industry PRINCIPLE OF OPERATION The parts to be washed on the basket placed on a stainless rotary platform with a sliding system are subjected to rotary basket washing with water with high pressure detergent in a closed cabin to be placed. Washing process is carried out to clean oil, sawdust, dirt and waste from dirty surfaces from different angles by means of time-adjustable pressure water nozzles according to the part structure and pollution rate. By filtering the water with the cycle permanent system, it is designed to reduce the consumption of water, detergent, electricity and time (labor) with the least consumption of parts. OPTIONAL FEATURES - Steam Evacuation Unit - Stainless chrome body structure - Basket structure - Number of nozzles - Liquid level control system All kinds of parts washing machines can be manufactured in our company upon request.

Request for a quote

KERMAK MACHINERY

Turkey

The machine parts are made of 304 AISI stainless chrome material. High pressure water pump 800 crate washing capacity per hour Pressurized water spraying on the case is provided by special spray nozzles. Speed controlled conveyor system Visor and safety bars that can be adjusted according to the size of the frame Removable side covers for easy cleaning Internal water tank with a capacity of 500 liters. Anti-clogging sediment collector mechanical screening system 380V 50Hz 10kw electricity requirement Speed control panel for conveyor Electric control control panel Machine total length is 4 meters Washing Tunnel length is 3 meters. Height 165cm Width 100cm + 30cm electrical panel It can wash up to 600 * 400 * 350mm sized crates.

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

DOLFİN-KBN1 series parts washing machines are used before and after overhaul in repair and maintenance services, especially for washing large and heavy parts. Apart from revision workshops, it is also used for cleaning the surfaces before assembly or packaging in enterprises and factories that produce parts in series. They are special devices designed for large sized and heavy parts such as engines and parts of construction machines, power plant turbines. While the parts placed in the device are rotated on its own axis by means of the washing basket, pressurised detergent hot water is sprayed. Thanks to the pressure, temperature and chemical effect, all oil and dirt on the parts are cleaned.

Request for a quoteResults for

Machines for washing plastics - Import exportNumber of results

13 ProductsCountries

Company type