- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser processes

Results for

Laser processes - Import export

DOGRAR METAL

Turkey

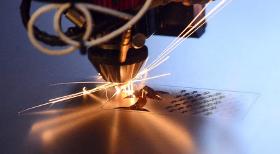

Tube and section laser cutting provides many advantages such as new design opportunities, declining manufacturing steps or easier welding methods from machinery to furniture sector. Thanks to Trumpf TruTube 3000 Fiber that we have included in our machiner in 2021. we can process tubes and sections up to 170 mm diameter or side dimensions. Laser cutting of tubes and sections, used in a wide range from the machinery industry to the furniture industry, offers you new pipe and profile construction possibilities that cannot be realized with traditional methods in pipe and profile construction. All kinds of contours and shapes that cannot be made with traditional methods are achieved with laser with low tolerances and at the same time saving time. In addition to the ease of processing, you can also simplify further manufacturing steps with the created contours. For example, with the positioning aids obtained by creating male and female contours on opposite sides

Request for a quote

PERGEL METAL

Turkey

Laser cutting is carried out by special machines. All of the machines have the latest technological features. A fine and successful cutting technique is applied. It also provides the expected success in PVC cutting. Because the machine is strong; it applies a fast process in thick material cutting, aluminum, galvanized cuts. In particular, laser cutting, foil-coated cutting processes give more effective results than other materials. The burn trace is minimal and minimal. Our company is successful in this regard.

Request for a quote

NOVELTY STEEL

Turkey

Laser cutting is a cutting process which enables cutting metallic and non-metallic materials with different thicknesses for metal fabrication works. The cutting operation is based on a laser beam which is guided, formed, and bundled. While traditional metal cutting processes involve applying large-scale tools with enormous power to the metal, the laser beam completes its task without any direct contact to the work piece. This prevents any wearing, deformation and damage to the tool and the work piece. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BACA MAKINE LTD.

Turkey

There are many different methods in the cutting process using lasers and bending which are used to cut or bend different materials into different shapes.

Request for a quote

TECHNIC MACHINES

Turkey

The coil-fed laser offers great advantages in coil laser cutting processes with the help of the continuous coil-fed laser cutting system. With the aid of a perfect construction and advanced software of the coil-fed laser machine, we provide our customers with precision, accuracy, and the possibility of rapid production from the coil to the laser cutting system. Advantages of the coil-fed laser cutting machine: • Results with minimal waste • Lower electricity consumption • Reduced labor costs • High production capacity • Low maintenance cost • NO investment in tools required • Maximum cutting flexibility • Clean, precise, and continuous cutting • Cutting bed design according to customer demand • Possibility of special design in coil-fed laser machine

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Laser cleaning is an exciting new laser process where contaminants, debris or impurities (e.g. carbon, silicon and rubber) are removed from the surface of a material by way of laser irradiation. Not only is this a low-cost solution, it is also the most environmentally friendly application technique compared to the conventional cleaning processes which are widely used in many industries around the world. Laser coating removal is an ablative process whereby laser energy is focused and absorbed by the surface, resulting in vaporization of the coating with minimal effect to the underlying level. This process can be applied to various materials including metal, plastics, composites as well as glass. APPLICATIONS Paint Removal Rust Removal Surface Preparation Facade & Fascia Cleaning Welding & Coating Pretreatment Art Restoration Mold Cleaning Contamination Removal Aerospace Parts Celaning

Request for a quoteResults for

Laser processes - Import exportNumber of results

9 ProductsCountries

Company type