- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser processes

Results for

Laser processes - Import export

DOGRAR METAL

Turkey

Tube and section laser cutting provides many advantages such as new design opportunities, declining manufacturing steps or easier welding methods from machinery to furniture sector. Thanks to Trumpf TruTube 3000 Fiber that we have included in our machiner in 2021. we can process tubes and sections up to 170 mm diameter or side dimensions. Laser cutting of tubes and sections, used in a wide range from the machinery industry to the furniture industry, offers you new pipe and profile construction possibilities that cannot be realized with traditional methods in pipe and profile construction. All kinds of contours and shapes that cannot be made with traditional methods are achieved with laser with low tolerances and at the same time saving time. In addition to the ease of processing, you can also simplify further manufacturing steps with the created contours. For example, with the positioning aids obtained by creating male and female contours on opposite sides

Request for a quote

TEPROSA GMBH

Germany

We are specialized in performing thermal shock testing of electronic and mechanical assemblies and have a lot of experience with the requirements of the automotive industry and medical technology. On behalf of our customers, we perform environmental and climatic tests according to customer specifications and applicable standards, thus uncovering optimization potential. We will be happy to advise you with regard to your testing tasks and, together with you, transfer the entire testing process into a specification sheet. OUR OPPORTUNITIES 2-chamber system air-air Test chamber volume up to 130 liters Temperature range hot chamber 50°C to 200°C Temperature range cold chamber -80°C to -100°C Change between chambers <15 seconds Maximum test material weight 25 kg State monitoring of the test specimens during the test

Request for a quote

BRM LASERS

Netherlands

Since laser cutters process virtually all materials, they are an asset to almost any organisation. There are so many opportunities and applications! From cutting small parts for scale models to cutting acrylic for POS displays like bread bins in supermarkets. In completely different industries, hundreds of satisfied customers work with a BRM laser cutter. Our best-selling BRM Original laser cutters are available in several sizes with working areas of up to 1000 x 1600 mm. If you are looking for a larger working area, please check our BRM Open Bed machines. These have a working area up to 1500 x 3000 mm. These larger machines are often used by production companies, among others. The technology of a laser cutter is fascinating! In the machine, a powerful beam of light is generated. When this beam comes into contact with a material, it evaporates. This allows you to cut through materials. Inside the machine is a glass tube

Request for a quote

3D-MICROMAC AG

Germany

Besides the processing of rigid and flexible materials on rigid substrates, we also offer the processing of flexible materials using sheet-to-sheet or roll-to-roll processes: - Laser micro structuring and ablation - Laser processing “on-the-fly” or “step and repeat” - Roll width up to 300 mm possible

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Excimer Laser-Lift-Off using line-beam systems - Laser drilling and ablation using scanner systems or mask projection - Laser engraving of optical materials - Materials: polymers, polymer compounds, glass materials

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Laser cutting, dicing, and filamentation - Laser drilling – available as trepanning or percussion process - Laser micro structuring and ablation, e.g. with FSLA technology - Laser micro engraving, both on the substrate surface and as sub surface engraving in transparent materials Laser-Lift-Off (LLO) using DPSS laser and scanner systems Materials: ceramics, metals, polymers, glass materials, semiconductors, compound material

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Polymer catheter shafts and components, as well as insulated wire and cable, can be precisely machined through non-contact laser ablation.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Tubes, sheets, and CNC-machined components can be laser-cut components. With laser beam sizes ranging from 20 to 300 microns, AMETEK EMC has the expertise to precisely create stents, frames, flex-shafts and instruments as well as cutting complex geometries with close feature-to-feature positioning, such as small holes or narrow slot arrays. Material thicknesses from 0.05mm to 4mm and tube diameters from 0.3mm to 100mm can be laser-cut with high precision and repeatability.

Request for a quote

SC PROFINOX SRL

Romania

We provide laser cutting services for stainless steel or aluminium sheets and pipes. High precision and fast execution are ensured by high-performance equipment and the experience of the Profinox team! Our laser cutting services have a number of benefits: Versatility – the tool can be used for a wide range of materials, with Profinox providing laser cutting services for stainless steel, aluminium or copper sheets and pipes; The power used for the laser metal cutting process is lower; The laser cutting procedure involves minimal deformation; Low costs for laser cutting; No contact between the part and the tool; Enhanced surface quality; Minimal burrs: this advantage provided by the laser metal cutting process also eliminates the need for further machining; Possibility to create and obtain complex shapes. Furthermore, the laser cutting process is silent and fast, ensuring a high precision of +/- 0.1 mm. If you have materials exceeding the maximum

Request for a quote

SC PROFINOX SRL

Romania

Are you looking for sheet metal and profile cutting services? Profinox provides guillotines and mechanical saw machines. By using them, cutting time and costs will be greatly reduced! If you need linear edge sheet metal cutting processes at a lower cost than the laser cutting process, we recommend that you opt for guillotine sheet metal cutting – an ideal machine for performing such cutting tasks. If your needs include metal profiles that you want to cut to certain lengths and angles, we also have a high-performance mechanical saw with a high cutting speed. Therefore, whether you are looking for sheet metal or metal profile cutting services, Profinox will meet your needs.

Request for a quote

CUSTOM CRAFT LIMITED

United Kingdom

In a world where consumers have more choices than ever, brands must find ways to stand out from the crowd. One way to do this is with laser engraving. Laser engraving uses a concentrated beam of light to create an image on a substrate. This process can be used on various materials, but it’s especially well-suited for wood. Laser-engraved wood has a unique look that helps it stand out from other printed materials. The rich colors of the wood are brought out by the laser engraving process, resulting in a stunning visual that is sure to capture attention.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

PERGEL METAL

Turkey

Laser cutting is carried out by special machines. All of the machines have the latest technological features. A fine and successful cutting technique is applied. It also provides the expected success in PVC cutting. Because the machine is strong; it applies a fast process in thick material cutting, aluminum, galvanized cuts. In particular, laser cutting, foil-coated cutting processes give more effective results than other materials. The burn trace is minimal and minimal. Our company is successful in this regard.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting bending aluminum sheet metal parts

Request for a quote

NOVELTY STEEL

Turkey

Laser cutting is a cutting process which enables cutting metallic and non-metallic materials with different thicknesses for metal fabrication works. The cutting operation is based on a laser beam which is guided, formed, and bundled. While traditional metal cutting processes involve applying large-scale tools with enormous power to the metal, the laser beam completes its task without any direct contact to the work piece. This prevents any wearing, deformation and damage to the tool and the work piece. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is laser cutting and bending. The material is stainless steel. The finish is cleaning and deburring.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is aluminum. The process is CNC laser cutting and bending.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is aluminum/stainless steel. The process is CNC laser cutting and bending. The finish is sandblasting and anodizing.

Request for a quote

FÖHRENBACH GMBH

Germany

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

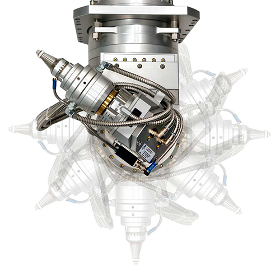

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR Stainless steel: SS304, SS316 Aluminum alloy Process: Flame/plasma/laser cutting Punching/bending CO2 welding Machining Application: Agricultural & farm machinery Off-shore industry Construction equipment General machinery

Request for a quoteResults for

Laser processes - Import exportNumber of results

135 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (47)

- Laser apparatus and instruments (8)

- Metal engraving - machine tools (7)

- Laser printing (6)

- Medical Equipment (6)

- Cutting - steels and metals (5)

- Lasers - medical applications (5)

- Steels and metals - welding and brazing (5)

- Import-export - medical and surgical equipment (3)

- Bending - steels and metals (2)

- Construction - Machines & Equipment (2)

- Import-export - electrical and electronic equipment (2)

- Industrial sheet metal work (2)

- Medical and surgical instruments (2)

- Pad printing (2)

- Shop fittings (2)

- Aluminium alloys (1)

- Brakes, servo-brakes and accessories (1)

- Cars - electrical and electronic parts and components (1)

- Chemical metal treatment (1)