- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- total solid

Results for

Total solid - Import export

HARRER UND KASSEN GMBH

Germany

NIR– InLine measurement device, For continues measurement of organic components Description The HK4 is an NIR (Near Infrared) In Line measurement device with state of the art technology. Which can measure all organic components in solids like meat and in liquids with different viscosities like milk, oil. The HK4 can be installed at pipelines, tanks / vessels, cutters, mincer, etc.. With only one measurement you can measure simultaneously valuable components like fat, protein, lactose, solids content, etc. for the dairy industry and fat, protein, collagen, water, etc. for the meat industry. Through the modular construction (Sensor and evaluation unit are separate), the sensorcalibrations.

Request for a quote

FLOTTWEG SE

Germany

Transport and disposal costs, at over 70 percent, represent by far the largest cost item in sludge dewatering. A powerful dewatering assembly is thus an important criterion. With a Flottweg HTS Decanter in the C series, you can achieve the highest possible total dry solids in the dewatered sludge, thereby continuously saving on transport and disposal. More than 50 years of experience in the dewatering of sewage sludge and continuous further development have gone into the design of the Flottweg HTS Decanter. This experience, combined with references from the entire world, makes Flottweg one of the leading providers of mechanical separation technology. The HTS Decanter is attractive for its performance, its efficiency, and its high cost-effectiveness. The decanters in the Flottweg C series cover a throughput range from about 5 to over 150 cubic meters per hour. We can offer you comprehensive know-how and customized systems.

Request for a quote

FLOTTWEG SE

Germany

Sewage sludge dewatering offers enormous potential savings for operators of sewage treatment plants. Dewatering sludge means reducing the quantity of sludge for disposal. Depending on system capacity, 1 percent more dry substance can lead to cost savings in the five- to six-digit range. The dewatering performance of the Flottweg Xelletor Series is significantly better than even its predecessors. It sets new benchmarks for throughflow, dry substance, and polymer and energy consumption. The Xtra in performance at low consumption in comparison with our high-performance C Series: ►Xtra dewatering performance: Up to 10 percent less sludge volume due to higher total dry solids in dewatered sludge ►Xtra polymer savings: Up to 20 percent savings on flocculant consumption ►Xtra capacity: Up to 15 percent more throughflow ►Xtra energy savings: Up to an additional 20 percent energy savings

Request for a quote

ÁRIK 21 - AGRO KFT

Hungary

Parameter Specification Total Solids 72% min Fat 10% min Milk Solids Non-Fat 15% min Sucrose 45% min Protein 2% Vitamin A 700 mcg / 100g Vitamin D 120 mcg / L / 100g

Request for a quote

ATMOSFER MACHINERY

Turkey

Our RO system offers a versatile production capacity from 250 to 4,000 liters per hour. It features a stainless steel high-pressure pump and a user-friendly 7" touch screen PLC interface. To ensure precision and efficiency, a digital flow meter measures production and wastewater quantities, and flow rates can be adjusted with a stainless needle valve. Pressure sensors on the touch screen monitor network and membrane input pressure, automatically stopping the system and displaying errors if preset pressure values are exceeded. Users can monitor the Total Dissolved Solids (TDS) value on the touch screen. The system includes three high-quality solenoid valves controlled by the PLC microprocessor for precise management. The electric panel ensures safety and longevity with Motor Protection and phase Protection functions. The system is housed in a visually appealing stainless cabinet.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LMK THERMOSAFE LTD

United Kingdom

For fast, efficient and safe drum heating - a great replacement for old inefficient and expensive steam ovens. Fully ATEX, IECEx and ETL (NA) certified. MELTS SOLIDS ¤ HEATS LIQUIDS ¤ TOTALLY SAFE Designed to heat 205L drums or smaller steel vessels. THERMOSAFE® is a proven alternative to multi-drum ovens and the solution to a host of process heating problems, even in Hazardous Areas SIMPLE SAFE EFFICIENT FAST CLEAN FLEXIBLE MAINTENANCE FREE T: +44 (0)1440 707141 E: sales@drumheating.com

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

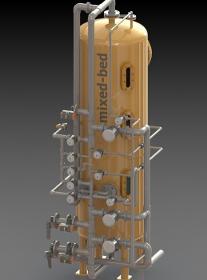

Both cation and anion resin can be feed in to an ion exchanger tank and mixed to create a mixedbed ion exchanger. A mixedbed ion exchanger is more complicated than other types of ion exchangers because it has to separate and regenerate the two resins. The carefull mixing of the cation and anion resin allows a very high degree of deionization. Mixed bed ion exchangers produce the highest quality demineralized water of any of the ion exchanger units. Working mixedbed ion exchangers deionize water with up to 50 ppm TDS (Total Dissolved Solids). Polishing mixedbed ion exchangers are located after cation and anion exchangers or reverse osmosis units Strong acid cation and strong base anion resins are used in mixedbed ion exchangers, as complete demineralization is the objective. A small volume of inert resin can also be used to facilitate separation of the cation and anion resin beads during regeneration

KGA ENCLOSURES LTD

United Kingdom

Product Features: • All steel, heavy duty construction designed to house heavy, heat producing items such as power supplies. • Bottom of unit is 16 gauge steel, top is 18 gauge steel. • Finished in a rugged beige powder coat. • Top half is of an upside down "U" shape design for easy removal, bottom half is also "U" shaped but includes a fold on all sides including front and back for extra strength and mounting of top case. • Top case section is heavily ventilated for excellent air circulation with an attractive slant (also doubles as a lifting area - both front and back). • Top lip extends 0.75" (19mm) on both sides adding 1.5" (38mm) to the total depth. • Bottom is solid except for 4 holes for mounting heavy duty rubber feet. • Includes nickel plated self-tapping screws and screw on 0.75" (19mm) high, rubber feet (1421T7).

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series DF 050 - DF 600 Mixing, stirring, cooking and sterilising are basic operations in food production and processing. The BOLZ-SUMMIX cookers with their conical construction and rotating mixing screw, have proven particularly useful for processing natural products such as coffee beans, cocoa nibs, gluten or nuts such as chestnuts. Various processes can be realised such as a heat treatment process by direct steam injection and heated jacket with continuous mixing, injection/absorption of process liquid, cooking and sterilising as well as extraction of components. Special properties for the customer’s benefit: Short process time with gentle and effective product mixing and intensive heat transfer Injection of steam via a ring channel Vacuum and pressure rated equipment Total drain of solid and liquid in a short time Flexible hence suited for a wide range of products, process and heat treatment Quick adding of required process liquids

Request for a quote

BALABAN 54 MAKINA DIS.TIC.LTD.STI

Turkey

These mixers are used to add the milk powder to milk or water. Mainly, these units are used to acquire milk by adding milk powder for applications where actual milk is not present as well as to increase the total amount of solid materials in the milk during yoghurt production. Capacity: 10000- 30000 LT/H

Request for a quote

SOLOVIAN

Turkey

Key Specifications/Special Features • Total solids content, (TSC), % wt.Min 61.5 • Dry Rubber Content (DRC),% wt.Min 60.0 • Non-rubber content % wt.Max (TSC minus DRC) 2.0 • Total Alkalinity (NH3)% wt • Min 0.60 • Max - • Mechanical Stability Time (MST) sec.Min 650 • Coagulum content % wt of TSC.Max 0.05 • Copper content, mg/kg,% of TSC.Max 8 • Manganese content, mg/kg, %of TSC.Max 8 • Sludge content, % wt of TSC. Max 0.10 • Volatile fatty acid (VFA).Max 0.20 • KOH number. Max 1.0 Good grades: 60% HA - 60 % DRC concentrated High Ammonia Latex 60% MA - 60 % DRC concentrated Medium Ammonia Latex 60% LA - 60 % DRC concentrated Low Ammonia Latex Packaging: Bulk / Drums / FlexiBag

Results for

Total solid - Import exportNumber of results

12 ProductsCompany type

Category

- Control boxes - electric (1)

- Dairy products (1)

- Detergents and soaps - professional (1)

- Drainage systems and equipment (1)

- Fats, edible (1)

- Foams, rubber (1)

- Heating, industrial - installations and equipment (1)

- Import-export - mechanical engineering (1)

- Powdered and condensed milk (1)

- Water purification - systems and equipment (1)

- Water treatment, industrial - systems and equipment (1)