- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing of

Results for

Processing of - Import export

EOSWISS PHARMA

Switzerland

We plan and perform your complete process validation. From the first gap analysis and risk management, planning, execution and reporting. We support you with full project management, providing support where needed. You free your ressources for your projects, we take care for validations and all connected activities. You reach your goals safely, quicker and faster.

Request for a quote

EOSWISS PHARMA

Switzerland

Freeze-drying is an important process for preserving and formulating pharmaceutical and biotechnological active ingredients. If an existing process is changed or transferred, the entire cycle must be modified. We advise on the adaptation of a freeze-drying cycle or scale up. Contact us for an initial discussion! Analysis We analyse existing data, model the process and verify the settings before the conversion. For them, this means: high transfer security, short project times, low overall costs. Adaptation of a freeze drying How do we go about it? For the time being, we analyse all existing data and "build" a model of freeze drying from it. The model is based on the physical principles and the real data of their current plant. Consequently, our predictions and forecasts are accurate. From the model, we obtain the settings for the new freeze-drying process. Before the step into production, these settings are verified with a small system.

Request for a quote

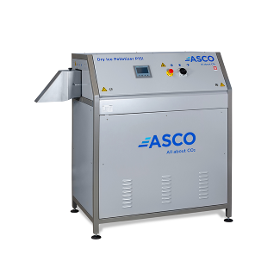

ASCO CARBON DIOXIDE LTD

Switzerland

The Dry Ice Pelletizer P75i with a production capacity of 750 kg/h (1'653 lb/h) is the workhorse among the ASCO dry ice pelletizers. It is built for longterm operation incorporating a heavy duty type hydraulic system controlled by an integrated PLC with touch screen interface. Fully automatic control of oil temperature and dry ice snow production process guarantees continuous dry ice production without any supervision right from the beginning. The P75i can be ordered as a version with a reduced noise level or with an automatic extruder plate changer. Simply change the production from one set pellet size to another size at the push of a button. The Dry Ice Pelletizer P75i is the most powerful model in the range of ASCO iSeries dry ice production machines. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P15(i) is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 150 kg/h (331 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As an optional model of ASCO's iSeries, it can be equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Whether for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P15(i) is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

BÜCHI AG

Switzerland

Glass-lined steel reactor: 250 - 10'000 liter Pressure: -1.0 (FV) to +0.5 bar Temperature: -60 °C (-90 °C) to +200 °C Material: Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, tantalum Chemical process equipment consisting of glass-lined reactors or mixing tanks with distillation overhead in borosilicate glass can be operated at full vacuum and low pressure. A large variety of chemicals can be processed in such plants due to the highly corrosion resistant materials used. The design varies between multipurpose product / process specific set ups. Feeders and receivers are made of glass for smaller units and of glass lined steel for larger setups. Shell and tube type heat exchangers are built with inner tubes made of borosilicate glass, glass-lined steel, silicon carbide, tantalum or other metals depending on process parameters and other requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÜCHI AG

Switzerland

Probes for process control Probes are available to measure the different process parameters. These values can be displayed on our monitoring instrument and recorded in our bls software, see measure & control. Frequently measured parameters are: temperature pressure stirrer speed torque pH IR probes, probes to control particle sizes etc. from other suppliers can be integrated into our pressure reactors or stirred autoclaves.

Request for a quote

MÜLLER MARTINI AG

Switzerland

The Vareo PRO is the most ideal perfect binder for print finishing specialists and printing plants that use conventional printing modes or are engaged in digital printing. The threeclamp perfect binder with a mechanical performance of up to 1,350 cycles per hour can be loaded manually or automatically with book blocks. Whether for medium, short or ultrashort runs, right down to runs of one copy, the Vareo is an allrounder and stands for outstanding binding quality. The first book can be sold, even from book blocks consisting of individual sheets.

Request for a quote

MÜLLER MARTINI AG

Switzerland

The SigmaLine lll connects digital printing and print finishing into one unique complete system, allowing fully automated production in one pass – from the PDF file to the gathered book block, even for VDP production down to print runs of one copy. With web widths between 20” and 42” and power of up to 1,000 fpm (305 m/min), it is the most flexible, efficient and costeffective system for digital printing applications on the market.

Request for a quote

MÜLLER MARTINI AG

Switzerland

The bookline will help you reliably produce large print runs using conventional printing processes with quick processing times. But it can also expertly handle individual products or small print runs with size changeovers from digital print products. Thanks to its userfriendliness the bookline is ideally suited as an introduction to industrial hardcover production. It provides the highest product quality even when used for a wide range of applications.

Request for a quote

KOMAX HOLDING AG

Switzerland

The bt 288 features two twisting lines, making it the perfect solution for efficient wire set processing – even where large quantities are involved. The Komax bt 288 is based on the proven and tested technology of the bt 188 T. With a second twisting line, this semiautomatic twisting machine offers virtually double the production efficiency without any reduction in processing quality. And with its small footprint, it takes up hardly any space at all. The bt 288 calculates the cut length automatically and – in conjunction with the flat gripper option – can be used to twist three or four wires. The intuitive software (operated via touchscreen) enables you to save the twisting parameters.

Request for a quote

BOSSARD GRUPPE

Switzerland

You create great products. Bossard Assembly Technology Expert services help you find the right fastening solutions for manufacturing and make your company more competitive by slashing time to market. Production engineers and product designers are full of continuous innovation, process optimization and efficiency – factors that are key to gaining a competitive edge in the manufacturing business. From the moment you begin to develop a new product, our Assembly Technology Expert services deliver the smartest solution for all possible fastening challenges. Using the three-stage methodology helps reduce your production time and significantly cut costs. Design – focusing on fastening joints to design perfect products Optimize – hone your fastening process to perfection Educate – become an expert in the science of fastening

Request for a quoteResults for

Processing of - Import exportNumber of results

12 ProductsCountries

Company type