- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change systems

Results for

Change systems - Import export

KASAG SWISS AG

Switzerland

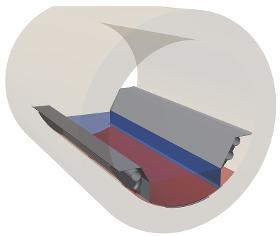

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote

KASAG SWISS AG

Switzerland

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure reactor system Reactor volume: 0.5 - 5.0 liter Pressure: -1 (FV) to +350 bar Temperature: -20 °C to +350 °C Material: stainless-steel, Hastelloy® Other materials, pressures & temperatures are available. This high pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure. The stainless steel or Hastelloy® reactors ensure high resistance against acids. The high torque magnetic drive ensures efficient mixing and stirring of the process media as well as excellent heat transfer. The system is equipped with a lifting device for vessel and electric heating. The modular setup of the limbo ls system allows changing or upgrading for new tasks at any time.

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure / high temperature reactor (HPHT) Standard Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +400 bar Temperature: -20 °C to + 400 °C Material: stainless steel, (Hastelloy® +400 °C) High-Pressure Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +500 bar Temperature: -20 °C to + 500 °C Material: stainless steel, (Hastelloy® +400 °C) This is our new high pressure and high temperature HPHT (high pressure high temperature) autoclave novoclave. This high pressure reactor system is designed for processes involving high pressures and temperatures. Safety features guarantee safe reactions under highest pressure. Designed, manufactured, and tested according to PED, AD2000. The modular setup of the novoclave system allows for changing the vessel size from 100 ml up to 600 ml using the same cover plate and electric heating block. Vessels are available in the following volumes: 100, 200, 300, 450, 600 ml.

Request for a quote

BÜCHI AG

Switzerland

Laboratory pressure reactor system - comfortable and simple operation Reactor volume: 0.25 to 5.0 liter Pressure: -1 (FV) to +60 / 200 bar Temperature: -20 °C to +250 °C Material: Borosilicate glass 3.3, stainless steel, Hastelloy® Other materials, pressures & temperatures are available. This multipurpose pressure reactor system is designed for the use of interchangeable glass and steel pressure vessels. Safety features guarantee safe reactions under pressure. The glass reactors ensure high resistance against acids, while allowing visual process control and monitoring. This is also possible under high pressure by using steel pressure vessels with sight glasses. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. The modular setup of the polyclave system allows changing or upgrading for new tasks at any time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÜCHI AG

Switzerland

Laboratory high pressure reactor system Reactor volume: 0.1 - 1.0 liter Pressure: -1 (FV) to +200 bar Temperature: -20 °C to +300 °C Material: stainless steel, Hastelloy® Other materials, pressures & temperatures are available This high pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure. The stainless steel or Hastelloy reactors ensure high resistance against acids. Visual process control and monitoring is also possible under high pressure by using steel pressure vessels with sight glasses. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. The fast action closure and vessel lift makes changing vessels quick and easy without the use of tools. The modular setup of the midiclave system allows changing or upgrading for new tasks at any time.

Request for a quote

BÜCHI AG

Switzerland

Compact metal laboratory pressure reactor / stirred autoclave with stirrer magnetic drive Reactor volume: 100 to 300 ml Pressure: -1 to +150 bar Temperature: -20 °C to +300 °C Material: Stainless steel, Hastelloy® Other materials, pressures & temperatures are available This multipurpose pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure. The steel reactors ensure high resistance against acids, while allowing high pressure reactions. The magnetic drive ensures efficient mixing and stirring of the process media as well as excellent heat transfer. The Fast Action Closure makes changing vessels quick and easy without the use of tools. The modular setup of the miniclave drive system allows changing or upgrading for new tasks at any time.

Request for a quote

KOMAX HOLDING AG

Switzerland

Alpha 488 S produces fully automatically Twisted-Pairs out of two single bulk wires completely cut-to-length and terminated, with all quality controls included. The modular composition of the system provides superb flexibility. Four processing stations at the wire beginning and two at the wire end offer extensive processing possibilities. The machine layout accommodates up to six processing modules. Wires with cross sections ranging from 2 × 0.22 mm² (AWG 24), optionally from 2 × 1.3 mm² (AWG 26), to 2 × 2.5 mm² (AWG 14), (processing set short open ends up to 2 × 1.0 mm²) can be processed in the highest quality. Alpha488S is available in the versions of four, seven and ten meters. In combination with the Komax crimping modules mci 722 or mci 712 and the Komax seals module mci 765 C as well as with the quick-change systems and the integrated quality monitoring systems Alpha 488 S ensures maximum process reliability and extremely short changeover times.

Request for a quoteResults for

Change systems - Import exportNumber of results

9 ProductsCompany type