- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- non-dairy

Results for

Non-dairy - Import export

SP GROUP

Spain

Our PE ECO is a polyethylene-based complex. It is a 100%-recyclable mono-material, meaning it can replace non-recyclable structures. This material has been developed by SP Group to meet the guidelines set out by the European Commission to increase the recyclability of packaging. PE ECO has been added to our Eco Range, which contains all SP Group’s recyclable and mono-material packaging solutions. Properties: It stands out for its transparency and its capacity to withstand heat treatments such as pasteurisation, hot-fill and microwaving processes. Applications: Market applications for this material: Processed meat and dairy products, such as cured sausage products and cheese, frozen fish and seafood, dried fruit and other dried food products, ranging from spices and superfoods to cereals and legumes. It is also a good option for many products in the non-food sector, for example personal hygiene products, gels and shampoos, and cleaning products, among others.

Request for a quote

FORMEX MAQUINARIA

Spain

CHARACTERISTICS OF THE MACHINES: -Production line consisting of six stations: oTray loader. oContainer dispenser. oCandy dispenser. oCooling tunnel. oCustard dosing unit. oThermosealing unit. -At the beginning of the line we manually place the trays in the loader. -In the next module, the dispenser automatically places the flan containers in the different positions of the tray. -The next unit is a dosing unit with which the caramel is dosed at a temperature of 170°C. -The trays pass through a tunnel with several fans to cool the caramel. -Afterwards we dose the custard. -Finally the unit for thermo-sealing the containers. ADVANTAGES: -Automated production for high volume production. -Six preparations are completed in a reduced space. -Safety in the work process.

Request for a quote

FORMEX MAQUINARIA

Spain

CLEANLY DOSES AND INJECTS FOOD MASSES OF DIFFERENT DENSITIES AND CHARACTERISTICS: viscous, liquid, soft, creamy, dense, sugary, etc. THE MIXTURE CAN HAVE SOLID PARTICLES INCORPORATED. For small and medium productions, although they can also be integrated into a working line or conveyor to achieve a higher degree of automation. IDEAL FOR DISPENSING PRODUCTS SUCH AS: muffins, plum-cakes, tartlets, custards, jams, sauces, fruit fillings, delicate fillings such as mousse, salad dressings, soups, Russian salad, creams with cereals, dairy products, etc. A WIDE RANGE OF ACCESSORIES AND DOSING OUTPUTS provide versatility when working with different products efficiently: mould conveyor, hose and hand gun, transfer pump, rotary cutting gun, injector nozzles, elevator, etc., elements that will make your work more precise.

Request for a quote

FORMEX MAQUINARIA

Spain

Dispenser for liquid, soft or semi-soft dough. -For medium and large productions, 170-230 trays/hour, approx. -Fully automatic: tray feed, positioning for filling and tray outfeed. -The volumetric dosing of the product is exact and guarantees the same dose in all the dosing nozzles. Different elements of the dosing machine can be custom-configured: number of nozzles, tray width, heated tank, conveyor belt, etc., to adapt to the characteristics of the product to be dosed. FOR MAKING: muffins, sponge cakes, sobaos, cakes, shortbread, cakes, pancakes, mayonnaise, marble sponge cake, yoghurt, custard, mousse, sauces, milkshakes, creams, products without solid particles.

Request for a quote

SAPLI SOLUTIONS

Spain

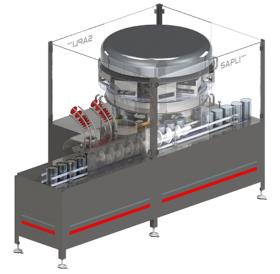

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAPLI SOLUTIONS

Spain

• Vacuumgassing seamers from Sapli are high performance solution for low and high production speeds. • The modular principle allows adding new seaming stations in the future, in case of increasing of production capacities. • Suitable for the seaming and vacuum gassing products in tinplate, aluminium, paperboard and plastic cans packaging across a wide range of industrial sectors. • Perfect sealing technology with adjustable working speeds. • Easy and intuitive format change. • Adjustable levels of residual O2 level after seaming, depending on the product requirements for guaranteeing a long shelf-life of the product. • Vacuum and gassing pressures are configurable, and can be monitored on each can seaming cycle • Guarantying the highest food security and produced with EU Declaration of Conformity. • Suitable for the wide range of tin cans formats, heights and diameters. • Multiformat principle allows working with lots of packaging formats at the same machine.

Request for a quoteResults for

Non-dairy - Import exportNumber of results

7 ProductsCompany type