- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linings

Results for

Linings - Import export

FORMEX MAQUINARIA

Spain

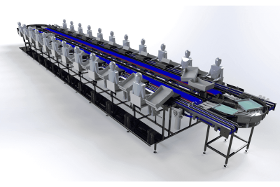

•Automatic and modular workstations for the production of muffins, cupcakes and other bakery products. •Modular lines consist of a series of machines prepared to flexibly meet your requirements. Mono-production or multi-production, mid-range or industrial, depending on your needs. •By studying your product and desired output we can create a workstation to suit your needs. The configurations are very versatile, allowing to extend the working line to increase production or diversify the product. •MODULES: Tray Loader + Capsuling Machine + Muffin Dispenser / Cupcake Dispenser / Pastry Dispenser + Topping Dispenser + Injector of already baked product. •The technical specifications vary depending on the modules and the final configuration of the line, please ask for a personalised quotation for the details of your desired line.

Request for a quote

GAICTECH

Spain

These Cleaning Lines are meticulously designed to enable operators to achieve high productivity levels and optimum performance in tuna processing. Tailored to meet the specific needs of each client, these lines offer optional features such as different designs based on available space, the choice between a closed circuit for unclean fish and clean loins (recommended) or a straight-line design, and the possibility of individual tables for each operator. Dimensions are adapted to client production requirements, and the construction is made of durable and hygienic stainless steel AISI 316-304. The lines facilitate the entry and exit of boxes with clean or unclean fish, either automatically or manually, and feature transport of unclean fish, clean loins, and waste in independent, differentiated areas. Production control options include the ability to monitor each operator in real time, with total and per operator yields and traceability. Custom programs can be tailored to client

Request for a quote

FRAMEX

Spain

Sporty line torch with adjustable elastic band for arm, head… 8 COB white lights with 3 lighting modes (2 direct modes + 1 flashing light). Available in a wide range of colors, battery powered (3xAAA not included) an presented in an attractive design box. 8 COB Lights. 3 Light Modes, Fixed and Flashing. 3 Batteries AAA Not Included

Request for a quote

UBIOTEX QUALITY LIFE S.L.

Spain

EFFECTS AND ADVANTAGESRelief cuts and small wounds in the distal part of the finger and nail. They do not take up space inside the shoe.COMPOSITION EXTÉRIEUR 70% nylon, 30% lycra elastic. INTÉRIEUR 100% gel pur MAINTENANCE Rinse with cold water, soap and air dry. Do not expose them to direct alue. Store in a cool, dry place, protected from sunlight. Once dry, before use, we recommend lightly sprinkle with unscented talcum powder inside. Do not iron and do not twist.

Request for a quote

UBIOTEX QUALITY LIFE S.L.

Spain

EFFECTS AND ADVANTAGESProtects against calluses, blisters and claw toes or hammer. No bulge within the shoe. Trimmable tube 15 cm.COMPOSITION EXTÉRIEUR 70% nylon, 30% lycra elastic. INTÉRIEUR 100% gel pur MAINTENANCE Rinse with cold water, soap and air dry. Do not expose them to direct alue. Store in a cool, dry place, protected from sunlight. Once dry, before use, we recommend lightly sprinkle with unscented talcum powder inside. Do not iron and do not twist.

Request for a quote

AV ALUMITRAN S.L.

Spain

AV Alumitran was the first company in Spain to manufacture thermal break profiles for its metalwork systems with high-density resin and polyamides

Request for a quote

PLÁSTICOS CLOSSA

Spain

The production of CLOSSA includes the injection of technical, aesthetic and design parts. We work for different sectors of the industry as White line industry. We manufacture precision technical parts for various sectors of the industry. They are made-to-measure plastic parts for a very demanding industry. We have a state-of-the-art 3D scanner machine that allows us to do reverse engineering or point cloud, among other things.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: •Production line consisting of four stations: - Two automatic injectors. - One automatic dosing machine for chocolate coating. - Unit for spreading the topping on top of the coating. •A single urn keeps the injectors and the dosing machine heated, so that the product is kept at a stable temperature at which the dosing is smooth and trouble-free. •The line is no more than 5 metres long and can be operated by a single person at the start of the conveyor. •A double conveyor belt system moves the trays with the completed product to the start of the line. ADVANTAGES •High degree of automation in a small space, 5 metres. •Handled by a single operator. •Uniformity in the product.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Diversity and complexity of products: -Living element: variable volume and shape. -Delicate and fragile: easy to damage during handling. Coated with gelatine, chocolate, etc. -Unsteady: Lightweight, easily dislodged. CHARACTERISTICS OF THE MACHINES: -Versatile production line that can operate with different types of trays and papers. -An Omron technology robot arm allows us to increase the versatility and efficiency of the whole line, as the same robot can work with different tray formats. -A dispenser for muffin and fiancée capsules that places the capsules on the tray. -A muffin dispenser with seven nozzles, with volumetric dose regulation. -Two interchangeable seed dispensers. ADVANTAGES -Uniformity of the product. -The automation of the whole allows us to obtain a production of approximately 8,400 macarons/hour or more than 8,000 units/hour in muffins, madeleines or financée.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT Elongated biscuit made of spongy dough with almond strips on the surface. Deposited in 450x900mm trays with 7 pieces per tray. The biscuit expands in the oven. CHARACTERISTICS OF THE MACHINES: -Production line composed of two stations: oGTF biscuit and biscuit dough dosing and forming machine. oTape topping unit. -The operator places the tray with moulds at the beginning of the conveyor and picks it up full at the end. -Afterwards he places it on the baking trolley. -Excess almond that has not stuck to the biscuit is recovered. -Moulds can be changed to make products with different number of fixed or rotating nozzles; smooth or curled. -Option to make other types of products in semi-liquid or hard dough. ADVANTAGES -Improved dosage, uniform pieces, faster production. -The dough does not degas. -Better ergonomics for the operator. -Removable head allowing complete cleaning and disinfection.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Lasagne with respective layers of pasta, bolognese, béchamel and cheese on top. -Two product sizes. MACHINE CHARACTERISTICS: -Three distinct zones connected by conveyor belts: oCutting area for the pasta sheet, placed by the operators in the moulds. oDosing area with five multi-purpose dosing machines, alternately positioned to apply the different layers of the lasagne. Volumetric dosing, equipped with servomotor for a homogeneous dosage. o Spun cheese dosing area. -From the control panel and by means of a touch screen we configure the speeds and accelerations of each belt to comply with the desired production. ADVANTAGES -Automated production for high volume processing. -All the processes are completed in a reduced space. -The entire line is easily disassembled for easy and effective cleaning, and its components are suitable for cleaning with pressurised water.

Request for a quote

FORMEX MAQUINARIA

Spain

CHARACTERISTICS OF THE MACHINES: -Production line consisting of six stations: oTray loader. oContainer dispenser. oCandy dispenser. oCooling tunnel. oCustard dosing unit. oThermosealing unit. -At the beginning of the line we manually place the trays in the loader. -In the next module, the dispenser automatically places the flan containers in the different positions of the tray. -The next unit is a dosing unit with which the caramel is dosed at a temperature of 170°C. -The trays pass through a tunnel with several fans to cool the caramel. -Afterwards we dose the custard. -Finally the unit for thermo-sealing the containers. ADVANTAGES: -Automated production for high volume production. -Six preparations are completed in a reduced space. -Safety in the work process.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

Mechanized parts for machinery for production, packaging and packaging lines.

Request for a quote

GAICTECH

Spain

The Tunidae Classification Line is a sophisticated system designed for the automatic calibration of tunas, leveraging both size and weight metrics to ensure the highest yield during the cooking process and facilitate selective storage. This line is capable of handling up to 50000 kg/hour for fish up to 15 kgs/unit with a single line, and offers the option for expanded production through multiple parallel lines for outline-based classification. Weight-based classification capacities are tailored according to the range of sizes to be classified, ensuring versatility and adaptability to specific production requirements. Constructed from durable and hygienic stainless steel AISI 316-304, the system incorporates advanced features such as the combination of outline and weight classification for large-scale productions with high accuracy. It also allows for the preliminary manual classification of species, or through machine vision cameras, to remove non-predominant species

Request for a quote

GAICTECH

Spain

Tailored to the specific needs of the seafood processing industry, this Pelagic Classification Line is engineered to automatically calibrate various pelagic species such as sardine, mackerel, and horse mackerel by size or weight. This ensures the highest yield during cooking processes and facilitates selective storage. Constructed from high-quality stainless steel AISI 316-304 for durability and hygiene, the line can accommodate up to 3 + 1 (oversize) classifications, with options available for additional classifications upon request. It features grading by divergent bars and mobile trays for the collection of calibrated sizes, with the option to install conveyors for each calibre. The machine's tilting can be adjusted based on the specific fish being graded, and the opening of the divergent bars is variable to accommodate different sizes. Pre-installation for fresh water supply is included to ease the movement of fish through the system

Request for a quote

GAICTECH

Spain

The Sardine Packing Line is expertly crafted to enhance the manual packaging process for pelagic species such as sardines, anchovies, mackerel, and horse mackerel, ensuring efficiency and optimal presentation. Constructed from high-quality stainless steel AISI 316-304, it offers durability and meets stringent hygiene standards. Tailored to the specific production requirements and packaging formats demanded by the market, this line is designed with ergonomics in mind, facilitating ease of use and minimizing operator fatigue. It features a special design for rectangular formats like ¼ Club, Dingley, or similar, allowing operators to achieve higher yields through dynamic packaging methods that result in an excellent presentation of the fish. The line also includes options for directing containers to grills or cookers and is equipped for integration with an automatic feeder of empty containers, further streamlining the packaging process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MEPLASJAR, S.L.

Spain

DESCRIPTION: Chalk line with 20 mts of cotton line. The green case is made of poliestirene and it has a perfect adjustement. Commonly used in the buliding and construction industry. The chalk line is he fastest way to mark straight guidelines on flat surfaces. The blister includes: 1 chalk line reel with 20 metres of cotton line. 1 chalk refill bottle (250gr) CHARACTERISTICS: • Green case for perfect adjustment. • Does not stain. • Comes loaded with 60 g chalk. • 20 metres of cotton line. • High retention of excess material • 250 gr chalk refill bottle

Request for a quote

PACKFEEDER

Spain

The in-Line series from Packfeeder has a wide range of systems and models of machines for unscrambling bottles of different dimensions, characteristics and materials, with speeds that can be adapted to the different production needs. The in-Line Packfeeder bottle sorter system can work efficiently with packages of very different volumes, from small dimensions of 3-4ml to large packages of more than 1L, at a wide range of speeds that can reach 500 u/min. The STD range of the in-Line series is comprised of different sized feeders that adapt to the different volume needs of packages and production speeds. They all provide extraordinary versatility, which allows for them to work with countless products, as they can be configured according to the needs of a wide range of industrial sectors.

Request for a quote

STE TECPHARM

Spain

The Granulation Line integrates into a single frame and control panel all options for solid forms production process: ■ Mixing and Granulation: High Shear Granulator. ■ Drying: Fluidized Bed Dryer. ■ Calibration: Conical and Cylindrical Calibrators. It minimizes the space requested in clean-room, reduces the risks of cross-contamination, and gives maximum versatility to process development and scalability studies.

Request for a quoteResults for

Linings - Import exportNumber of results

21 ProductsCountries

Company type